Space debris clearing method based on orbit ring

A space debris and orbital ring technology, which is applied to aerospace equipment, tools, transportation and packaging, etc., can solve the problems of high energy consumption, high cost, and inability to clean up space junk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

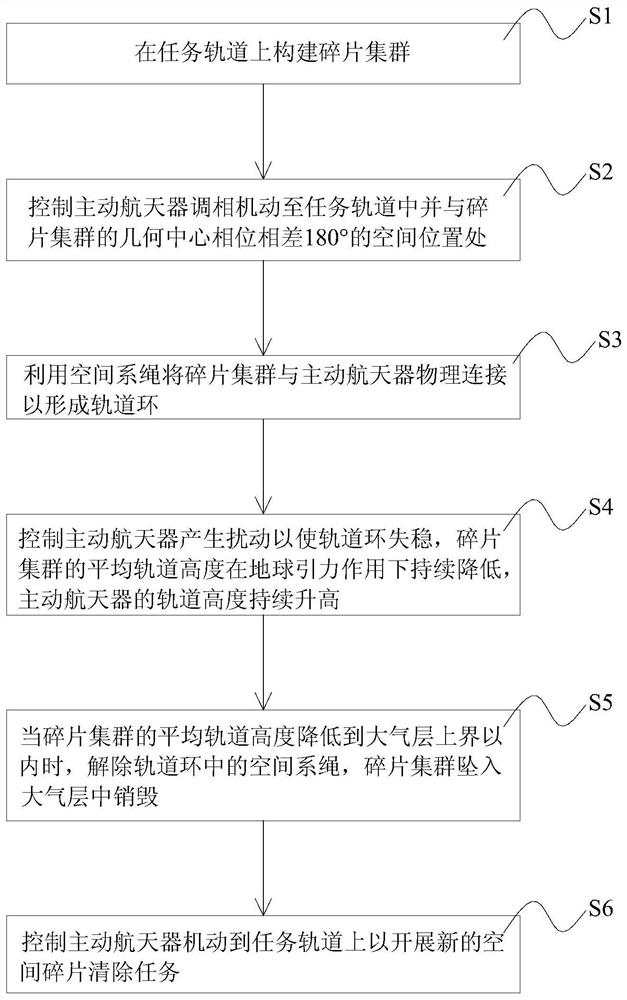

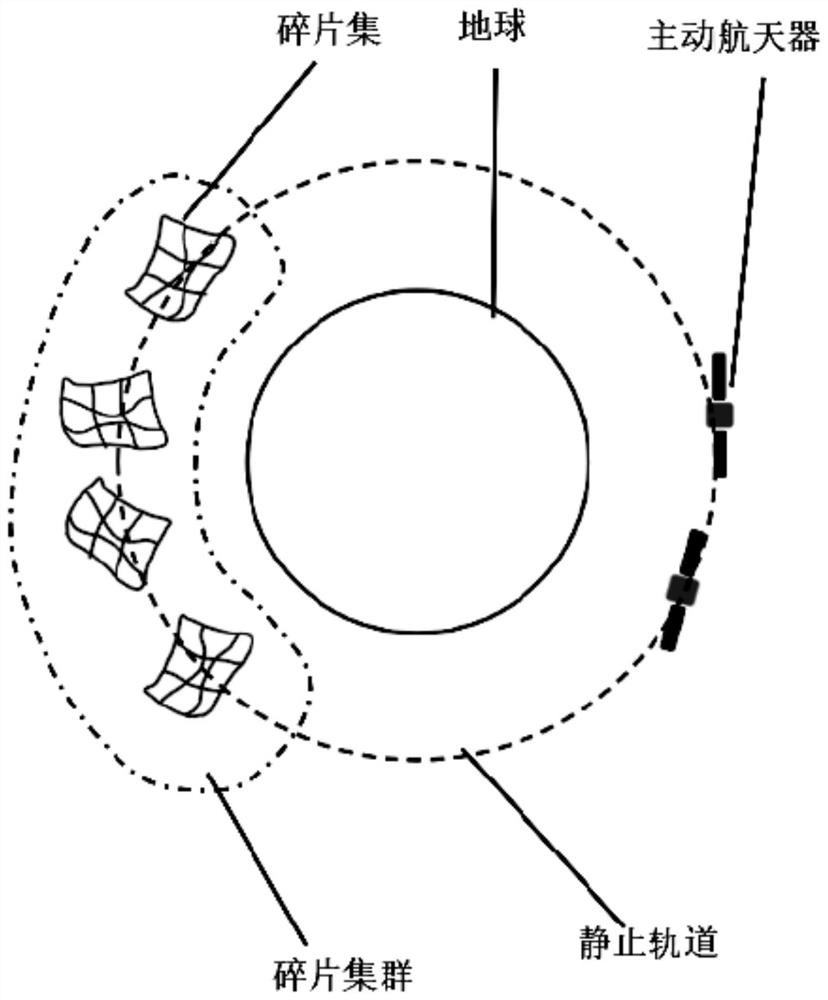

[0039] like figure 1 As shown, the preferred embodiment of the present invention provides a method for removing space debris based on an orbital ring, comprising the following steps:

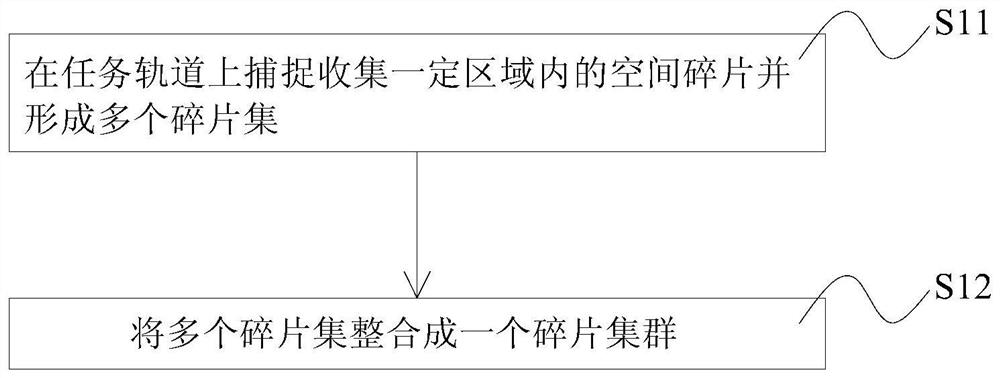

[0040] Step S1: Build a debris cluster on the mission track;

[0041] Step S2: Control the active spacecraft to move to a space position in the mission orbit with a phase difference of 180° from the geometric center of the debris cluster;

[0042] Step S3: Using a space tether to physically connect the debris cluster to the active spacecraft to form an orbital ring;

[0043] Step S4: Control the active spacecraft to generate disturbances to destabilize the orbital ring, the average orbital altitude of the debris cluster continues to decrease under the action of the earth's gravity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com