Packaging structure and conveying device

A technology of packaging structure and conveying device, applied in the directions of packaging, wrapping paper, transportation and packaging, etc., can solve the problems of forming tolerance, ineffective pressing, and inability to stack accurately, so as to reduce production cost, increase storage and transportation quantity, reduce damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The related technical content of the present invention will be clearly presented in the following detailed description of the preferred embodiments with reference to the accompanying drawings. Before going into detail, it should be noted that similar elements are denoted by the same reference numerals.

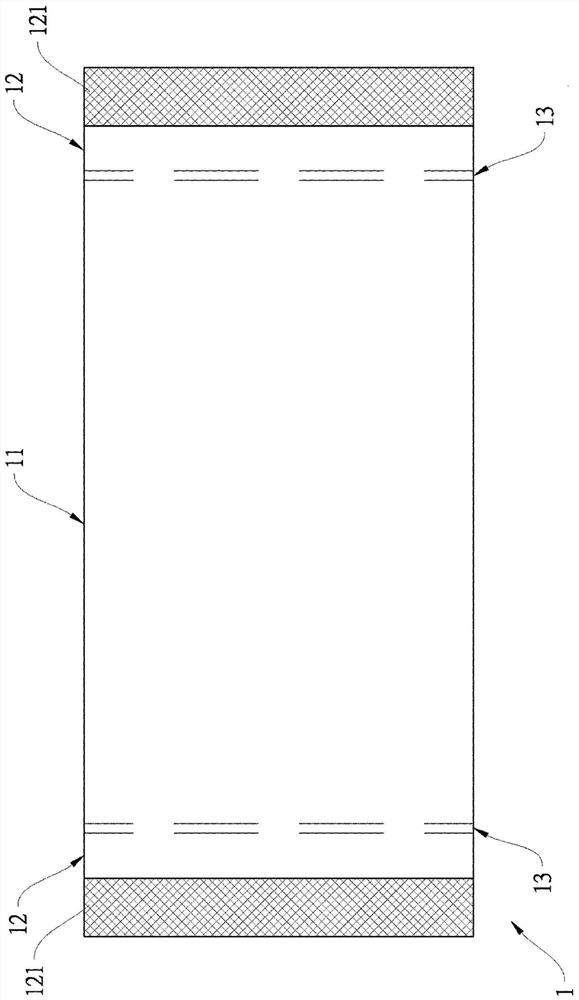

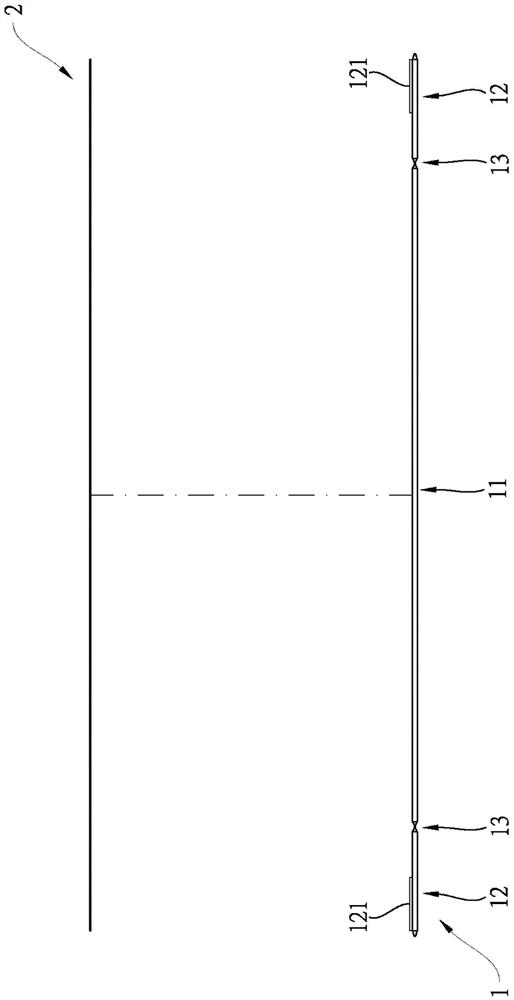

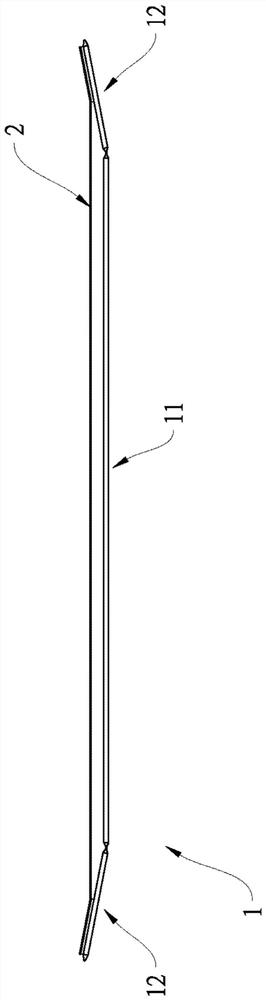

[0039] see figure 1 and figure 2 , is the first preferred embodiment of the packaging structure of the present invention, which comprises a carrying unit 1 and a film 2 with stretchability and disposed on the carrying unit 1 .

[0040] The carrying unit 1 includes a support plate 11 , and two side plates 12 respectively connected to opposite sides of the support plate 11 and capable of being bent relative to the support plate 11 . The two sides of the film 2 are respectively arranged at one end of the two side plates 12 away from the support plate 11, such as figure 1 As shown, the outer sides of the two side plates 12 are respectively provided with gluing areas 121...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com