Thermal control instrument mounting mechanism for thermal control of power plant

An installation mechanism and thermal control technology, applied in the direction of supporting machines, mechanical equipment, engine components, etc., can solve the problems of affecting efficiency, long maintenance time, inconvenience, etc., and achieve the effect of maintaining stability, fast installation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

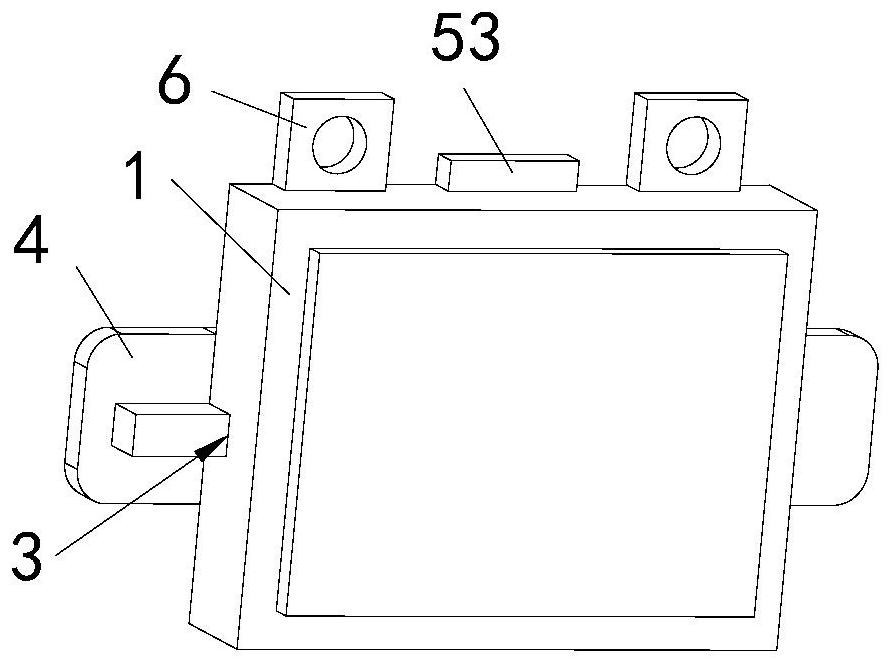

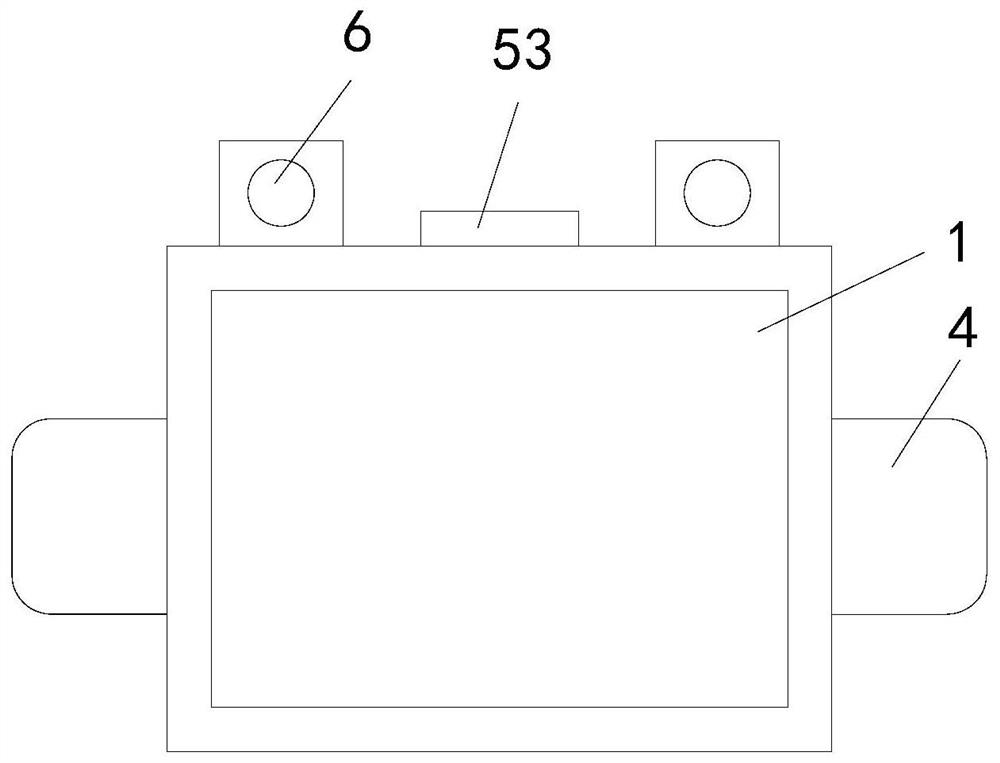

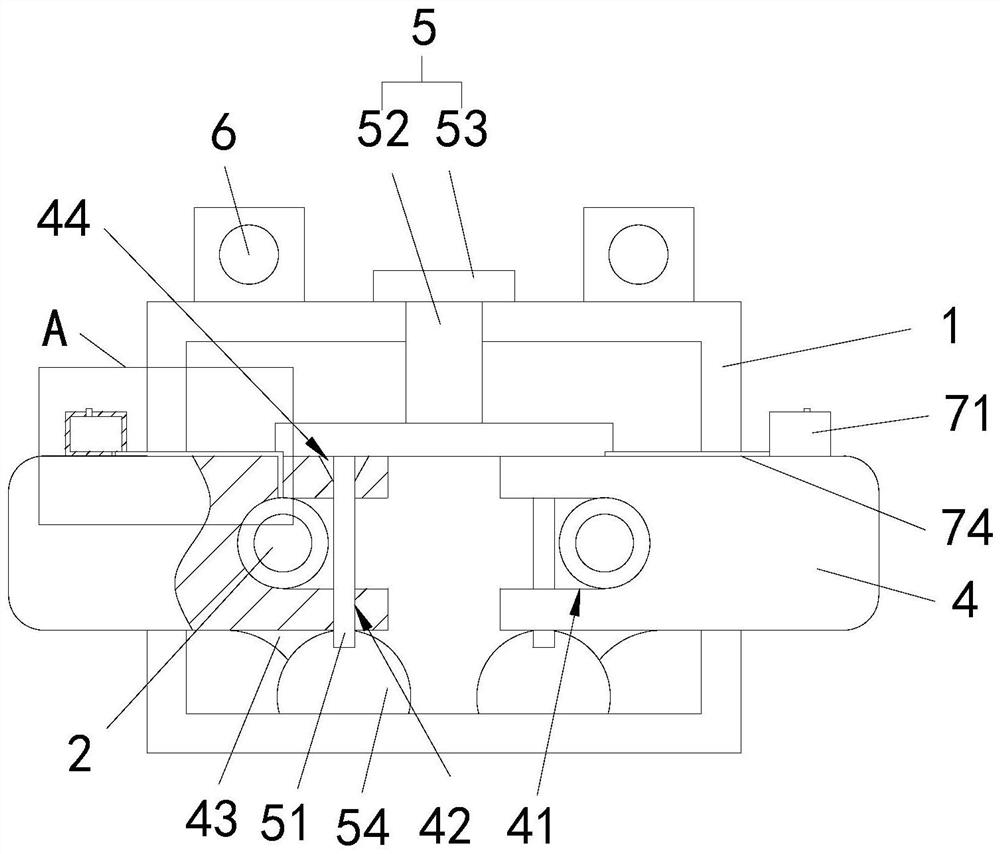

[0034] A thermal control instrument installation mechanism for thermal control in a power plant, comprising a thermal control instrument 1, and corresponding mounting nails 2 are arranged on the wall, and an installation groove 3 is arranged on the back of the thermal control instrument 1, and the installation groove 3 A mounting block 4 is slidably arranged, and a groove 41 corresponding to the mounting nail 2 is provided on one side of the mounting block 4;

[0035] A lubricating mechanism 7 is provided on the top surface of the mounting block 4 , and the lubricating mechanism 7 is used to lubricate the contact portion of the mounting nail 2 with the groove 41 .

[0036] Further, the installation slots 3 and the installation blocks 4 are arranged in pairs, and are arranged symmetrically on both sides of the back of the thermal control instrument 1 .

[0037] Further, the back of the thermal control instrument 1 is also provided with a locking mechanism 5, the side wall of th...

Embodiment 2

[0045] The present invention adds lubricating mechanism 7 on the basis of embodiment one; Specifically as follows:

[0046] Further, the lubricating mechanism 7 includes a lubricating box 71, the top of the lubricating box 71 is provided with an oil filling port 77, the bottom of the lubricating box 71 is provided with an oil outlet 72, and the mounting block 4 is provided with a fine hole 73, A capillary 74 is perforated in the thin hole 73 , one side of the capillary 74 faces the contact between the mounting nail 2 and the groove 41 , and the other side is inserted into the oil outlet 72 and communicates with the inside of the lubricating box 71 .

[0047] Further, a lubricating groove 75 is arranged around the inner surface of the groove 41 , and a lubricating strip 76 is arranged outside the lubricating groove 75 , and the area of the lubricating strip 76 is larger than that of the lubricating groove 75 .

[0048] By adopting the above-mentioned technical scheme, the lub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com