Gradienter for constructional engineering measurement

A construction engineering and spirit level technology, which is applied in the direction of measuring devices, measuring inclinations, instruments, etc., can solve the problems of offset placement of level instruments, lower measurement accuracy, unfavorable construction, etc., to prolong service life, ensure accuracy, and facilitate measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

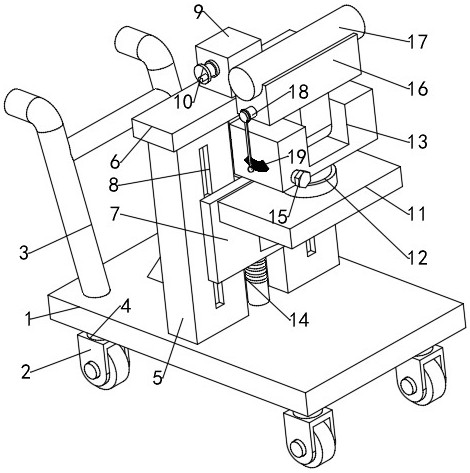

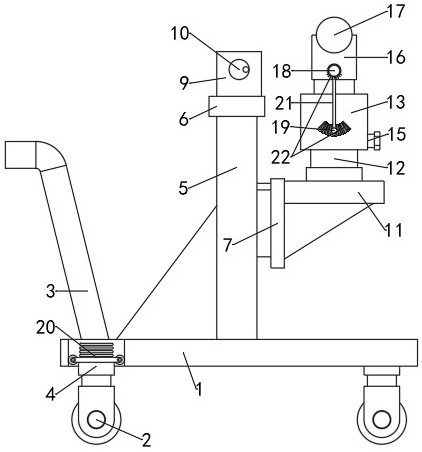

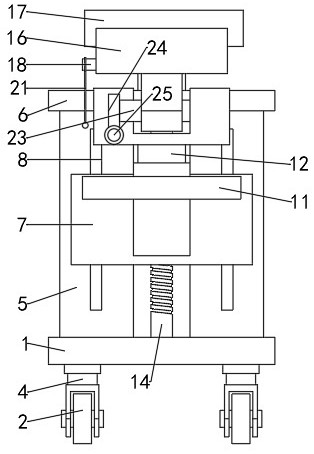

[0020] see Figure 1-4 , a level used for construction engineering measurement, comprising a base 1, the upper end surface of the base 1 is fixedly connected with a mounting frame 5, a reinforcing rib is fixedly connected between the mounting frame 5 and the base 1, and the mounting frame 5 is movable The base plate 7 is installed, and the upper part of the side of the base plate 7 facing away from the mounting frame 5 is fixedly connected with the mounting base 11, and the lower end of the mounting base 11 is fixedly connected with the base plate 7. , the cross-section of the frame 13 is concave, and the frame 13 is rotated through the assembly shaft 23 to be equipped with a base plate 16, and a level 17 is installed on the base plate 16; one side of the base plate 16 is fixedly connected with an assembly rod 18, and the assembly rod 18 is connected via The wire rope 21 is connected with a positioning block 19; one side of the frame 13 and the base plate 16 is provided with a...

Embodiment 2

[0029] In order to improve the working effect of the shock absorbing spring 20 and avoid the jamming of the assembly seat 4 and the base 1, this embodiment is improved on the basis of the embodiment 1, and the improvements are: the two sides of the assembly seat 4 The rollers fitted are attached to the inner wall of the base 1 so that the sliding of the assembly seat 4 is smoother and the damping effect of the damping spring 20 is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com