Hard seal safety valve detection equipment

A technology for testing equipment and safety valves, which is applied in fluid tightness testing, mechanical valve testing, liquid tightness measurement using liquid/vacuum degree, etc. Standards, low efficiency and other issues, to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

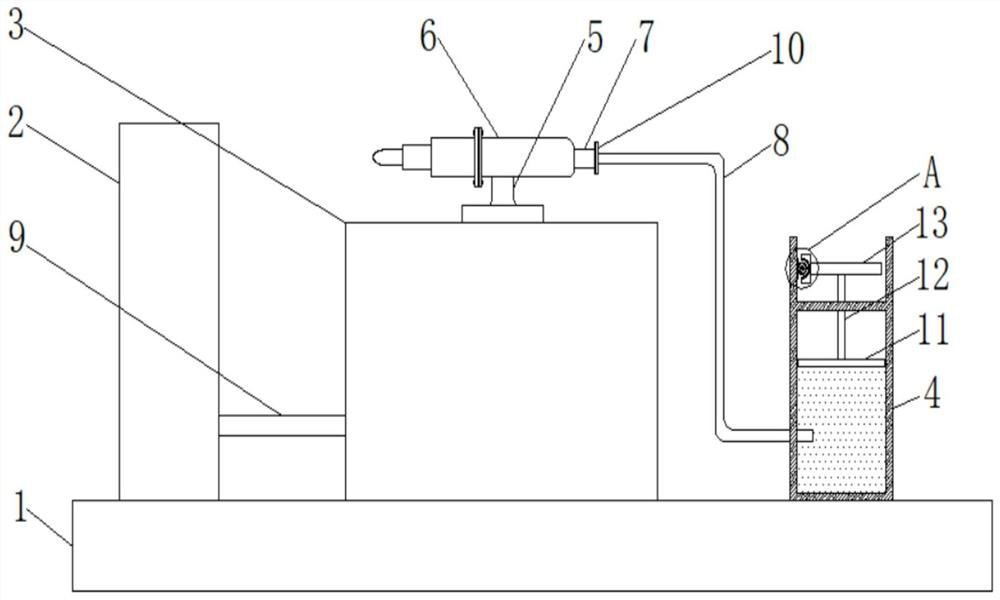

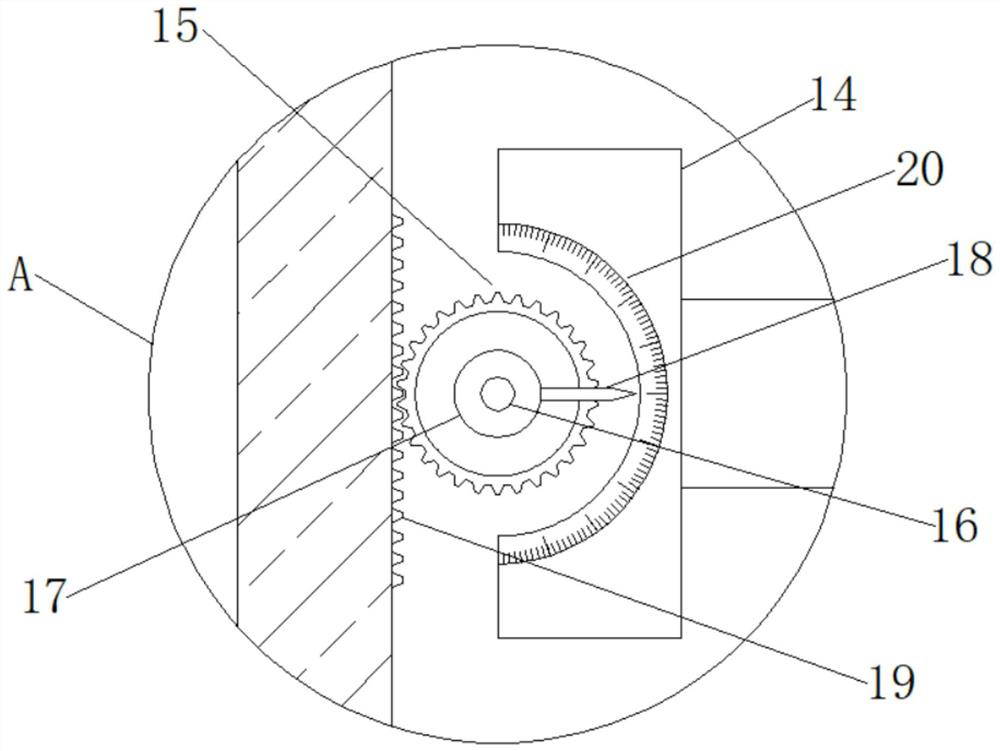

[0017] Attached below Figure 1-2 The specific implementation manner of the present invention will be described in further detail.

[0018] Depend on Figure 1-2 Given, the present invention provides the following technical solutions: a hard-sealed safety valve detection equipment, including a base 1, the top of the base 1 is fixedly connected with a pressurizing device 2, a pressurized container 3 and a detection tube 4, the pressurized container 3 The top of the external interface 5 is fixedly connected to the external interface 5, and the top of the external interface 5 is fixedly connected to the safety valve body 6. The right side of the safety valve body 6 is provided with a pressure relief port 7, and the inside of the pressure relief port 7 is provided with a conduit 8. The inside of the tube 4 is provided with a piston 11, the top of the piston 11 is fixedly connected with a push rod 12 extending out of the detection tube 4, the top of the push rod 12 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com