A device for detecting the air tightness of the internal pipeline of a diesel internal combustion engine

A diesel internal combustion engine and detection device technology, which is applied in the direction of measuring devices, internal combustion piston engines, fluid tightness testing, etc., can solve problems such as mechanical equipment shutdown, safety accidents, etc., and achieve the effect of improving efficiency and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] There are many internal pipes in the internal combustion engine, and the functions are obviously different, such as 8 and 8 Figure 9 The shown intake pipe, exhaust pipe, and other pipes have different functions and functions and different structures. The tightness of these pipes plays a very important role in the entire diesel internal combustion engine. The pros and cons directly determine the efficiency and service life of the internal combustion engine, so it is necessary to test the air tightness of these pipes.

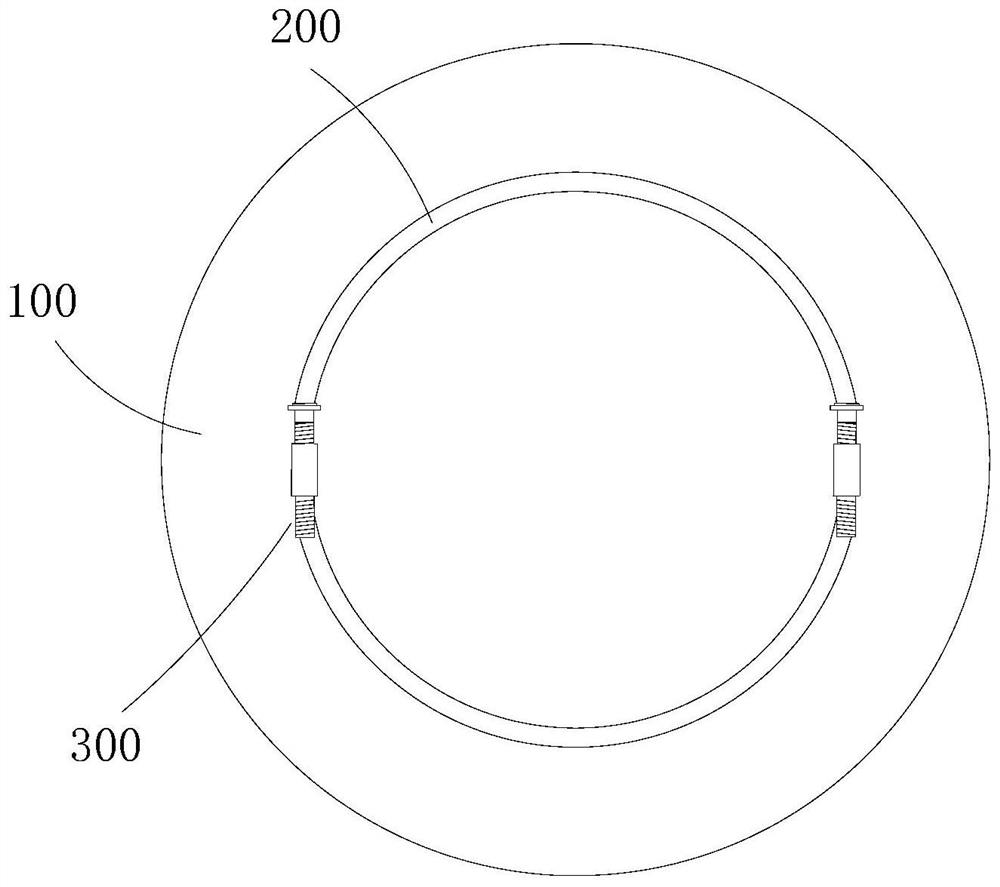

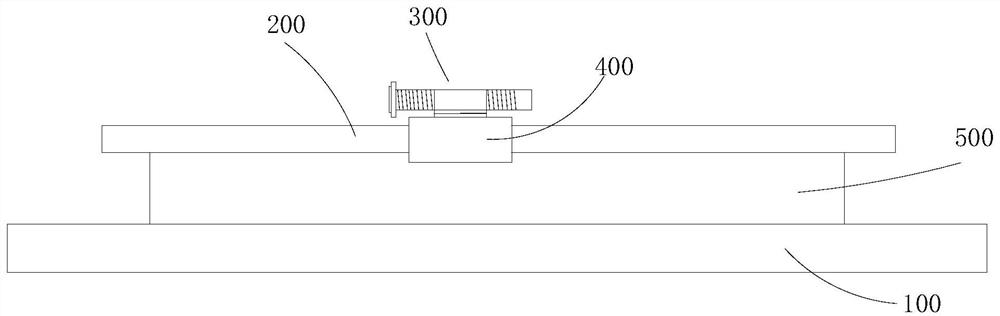

[0028] like figure 1 and figure 2 A device for detecting the air tightness of internal pipes of a diesel internal combustion engine is shown, including: an operation table 100, a rail 200 arranged on the operation table 100, and two head devices 300 arranged on the rail 200, which are realized by the two head devices. Blocking of openings at both ends of the pipe;

[0029] The two sealing head devices are respectively movably arranged on the track 200...

Embodiment 2

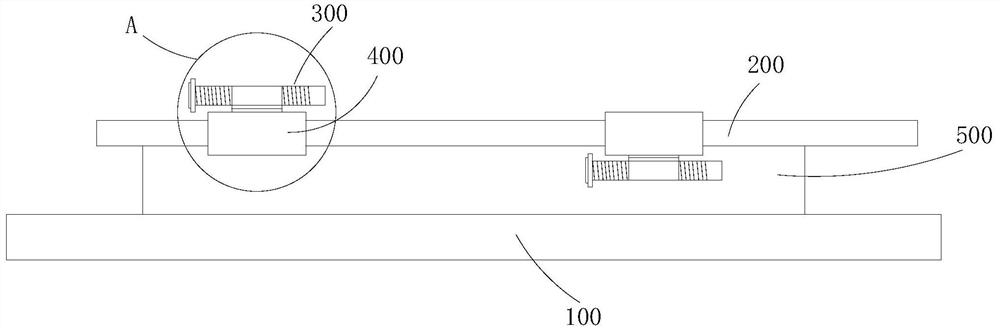

[0033] like image 3 and Figure 4 As shown, the head device includes a rotating base 301, the rotating base 301 is rotatably arranged along the annular ferrule 400, the rotating base 301 is provided with a fixed sleeve 302, and the fixed sleeve 302 is movably passed through. There is a sealing rod 303, and the sealing rod 303 can move back and forth in the fixing sleeve 302. In this embodiment, the sealing rod 303 is a screw rod, and the fixing sleeve 302 is a screw sleeve. The back and forth movement in the fixed sleeve 302; one end of the sealing rod 302 is provided with a sealing cover 304, and the sealing cover 304 is provided with an air inlet 305;

[0034] Since the annular ferrule 400 can only drive the head device to rotate along the track, the rotation of the rotating base 301 along the annular ferrule 400 finally realizes the rotation of the sealing rod, and realizes the rotation of the sealing cover 304 on one end of the sealing rod. The rotation of the sealing c...

Embodiment 3

[0038] like figure 1As shown, the track 200 is a closed circular track, which is convenient for realizing the integrity of the track and keeping the two head devices on the same horizontal plane; the cross-section of the track 200 is circular, which is convenient for the annular ferrule to slide along the track or Rotation is convenient and quick, saving time and effort.

[0039] like Image 6 and Figure 7 As shown, in this embodiment, a liftable device is provided between the track 200 and the operating table 100, which facilitates the lifting and lowering of the track, is convenient for adapting to various shapes of pipes, and improves the adaptability of the air tightness detection device; specifically , the lifting device is a lifting screw 600, the lifting screw is multiple, evenly distributed at the bottom end of the track, one end of the lifting screw is arranged at the bottom end of the track, and one end passes through the operating table and extends out of the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com