An air tightness detection device for a waste liquid bag production line

A technology of air tightness detection and waste liquid bag, which is applied in the direction of measuring device, liquid tightness measurement using liquid/vacuum degree, fluid tightness test, etc., which can solve the problem of long inflation time and bag air tightness detection efficiency Low cost, long time spent on bag air tightness detection, etc., to shorten the time, improve the effect of pressing and positioning, and shorten the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is a specific embodiment of the present invention and a further description of the technical solutions of the present invention in connection with the accompanying drawings, but the present invention is not limited to these embodiments.

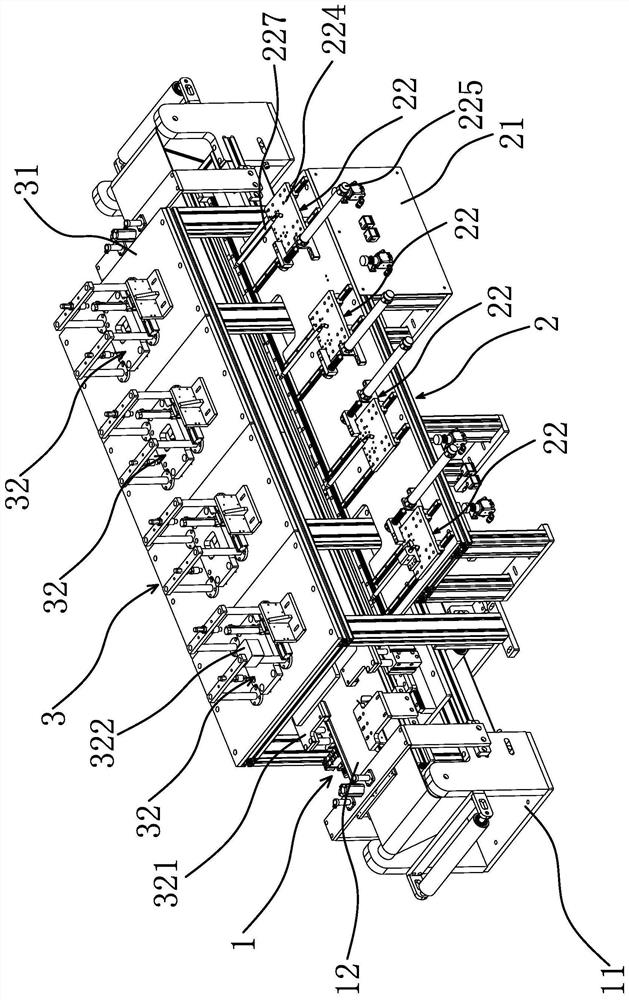

[0029] Such as figure 1 As shown, the air tightness detecting device of this waste liquid bag includes a waste liquid bag conveying line 1, a gas pressing mechanism 2, a compression bag mechanism 3, a fixing assembly 4, and a restricted component 5, a compressive bag assembly. The 32 and the gas pressing assembly 22 have several, and several compressive bag assemblies 32 are disposed on the rack 2 31, and the plurality of measurement pressing assemblies 22 are disposed along the lateral intervals of the rack 21, and the compression bag assembly 32 and The gas pressing assembly 22 corresponds to one by one.

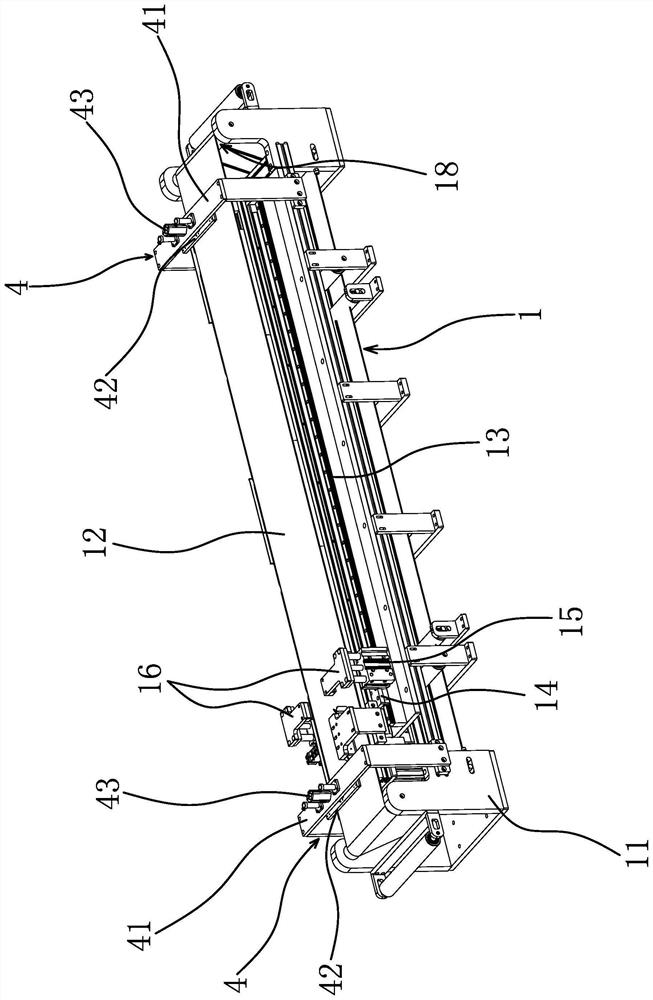

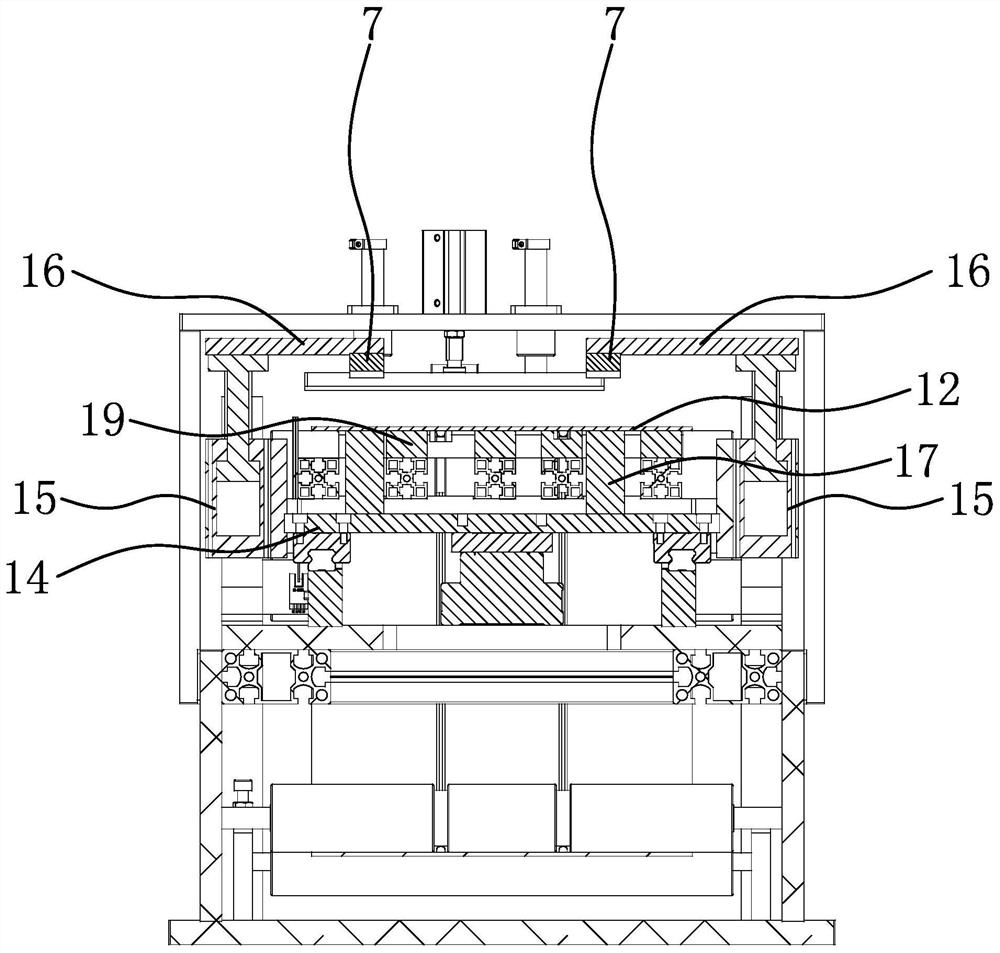

[0030] Such as figure 2 , image 3 and Figure 4 As shown, the waste liquid bag conveying line 1 includes a frame three 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com