High-efficiency energy-saving relay

A high-efficiency energy-saving, relay technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems that the relay cannot be damped, the relay cannot be placed in a safe position, and the relay is not easy to fix, so as to facilitate installation and disassembly. Fixed, easy to adjust, convenient shock absorption protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

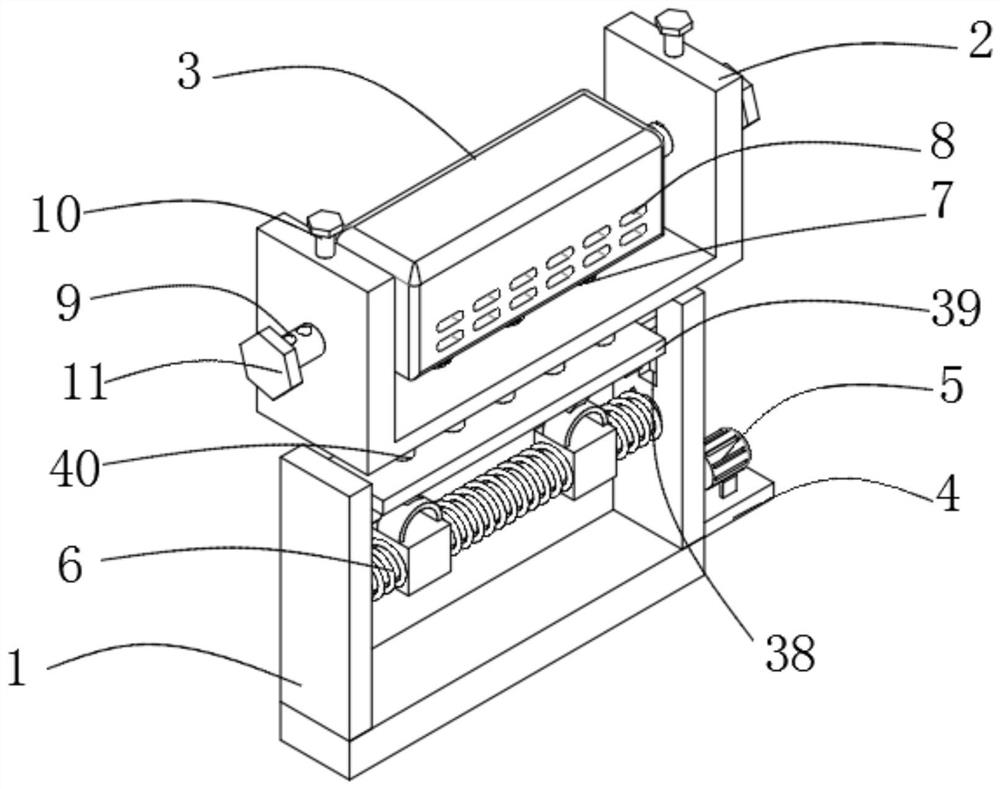

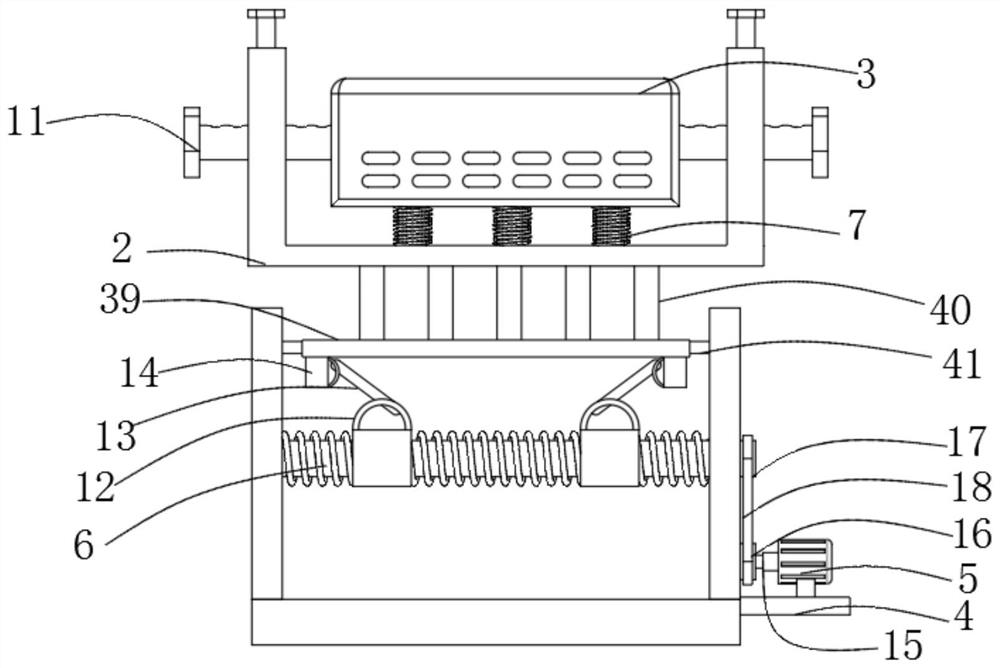

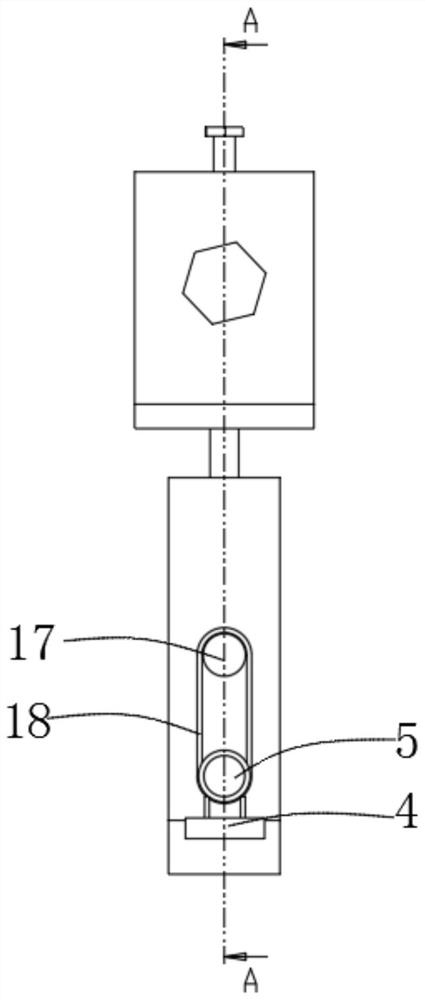

[0037] The following is a specific method of using a high-efficiency and energy-saving relay: first, adjust the height of the relay box 3, connect the driving motor 5 to the power supply, and the driving wheel 16 drives the driven wheel 17 to rotate through the rotating belt 18, and then drives the two-way threaded column 6 Rotation, when the two-way threaded column 6 rotates, it drives the movable screw sleeve 12 to move laterally, and then drives the moving rod 13 to move longitudinally, and further drives the moving block 14 to move longitudinally, and completes the adjustment of the height of the relay packing 3. According to the size of the relay packing 3 , move the pressing column, insert the clamping column 10 into the card slot 22 to complete the fixing of the relay box 3, and then connect the relay to the power supply.

Embodiment 2

[0039] It should be further explained that when the relay module 20 needs to be disassembled, by pressing the pressing plate 33, the first block 29 is pressed against the second block 30 so that it is completely compressed into the limiting groove 30, and then the installation The slide block 28 can be pulled out from the second installation groove 27 to complete the disassembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com