Personnel transportation vehicle

A technology for transportation tools and personnel transportation, which is applied in the field of transportation vehicles for personnel transportation, and can solve the problems of spongy debris being thrown outwards, increased cleaning efforts, and easy aging and cracking of leather skins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

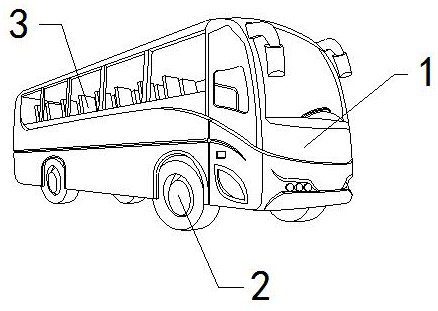

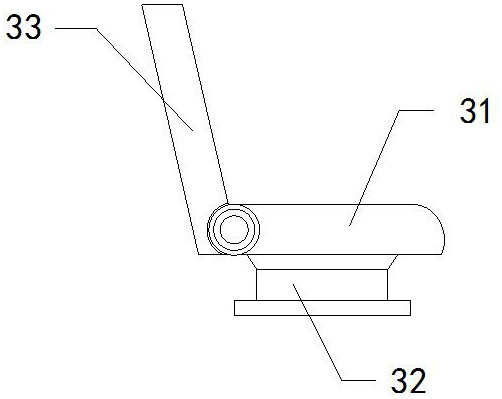

[0027] The present invention provides a means of transportation for transporting people. Its structure includes a passenger car 1, moving wheels 2, and seats 3. The moving wheels 2 are movably engaged with the bottom of the passenger car 1. The seat 3 is installed inside the passenger car 1. Position; the seat 3 includes a backrest 31, a support seat 32, and a cushion 33. The backrest 31 is embedded in the upper end of the support seat 32, and the seat cushion 33 is hinged to the left side of the backrest 31.

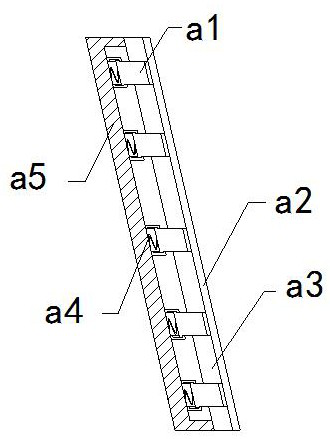

[0028] Wherein, the seat cushion 33 includes a telescopic plate a1, an outer skin a2, an inner cushion a3, an elastic strip a4, and an outer frame a5. In the inner position, the outer skin a2 is fixed on the right side of the inner pad a3, the elastic strip a4 is installed between the rear end of the outer skin a2 and the inner side of the outer frame a5, and five telescopic plates a1 are provided, and Evenly di...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the collection tank a14 includes a guide block c1, a bottom plate c2, and a contact plate c3, the guide block c1 and the contact plate c3 are an integrated structure, and the contact plate c3 is embedded and fixed on the inner side of the bottom plate c2 , the upper surface of the guide block c1 has an arc-shaped structure, and the sponge debris on the contact plate c3 can be guided into the inner position of the guide block c1 through the guide block c1.

[0036]Wherein, the guide block c1 includes a transition block c11, a clamping plate c12, a booster bar c13, a sleeve frame c14, and a deformable block c15. The transition block c11 is movably engaged with the sleeve frame c14, and the clamping plate c12 and The transition block c11 is an integrated structure, the booster bar c13 is installed between the transition block c11 and the inner side of the sleeve frame c14, the deformation block c15 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com