Reactive flame retardant vinyl organosilicon caged thiophosphate compound, and preparation method and application thereof

A technology of vinyl silicone and reactive flame retardant, which is applied in the direction of organic chemistry, chemical instruments and methods, and compounds of Group 5/15 elements of the periodic table, etc., which can solve the problems of poor dispersion, affecting the mechanical properties of the matrix, and the amount of addition Large and other problems, to achieve the effect of good char formation, overcome the decline in mechanical properties, good char formation and anti-melt dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

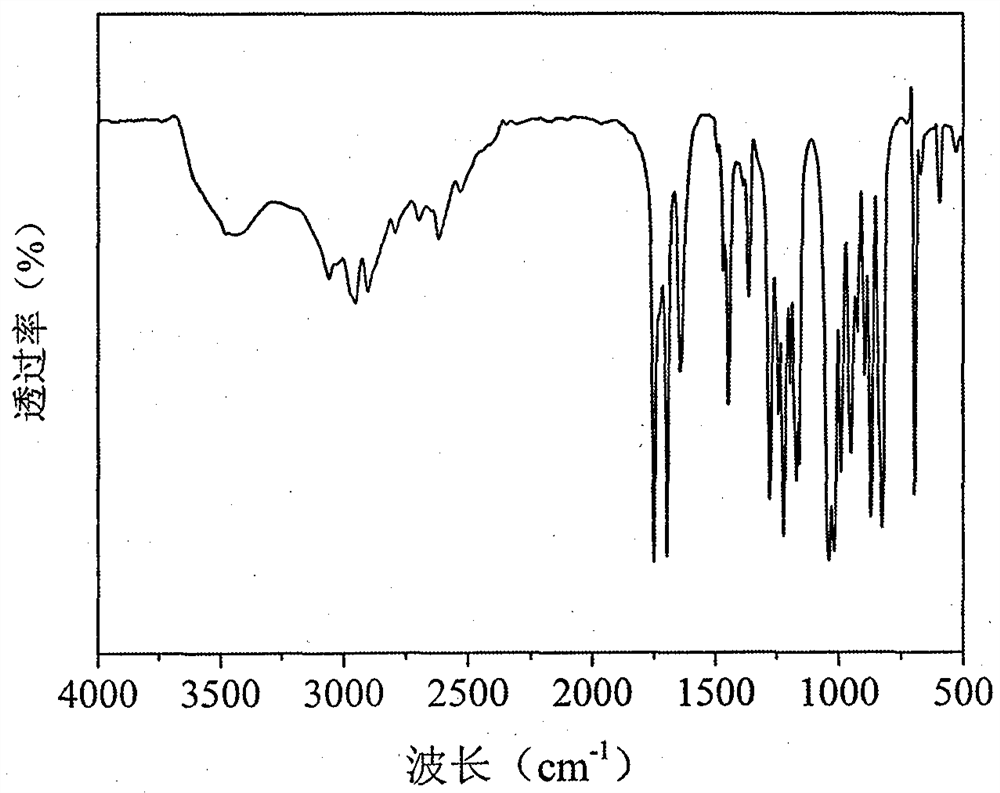

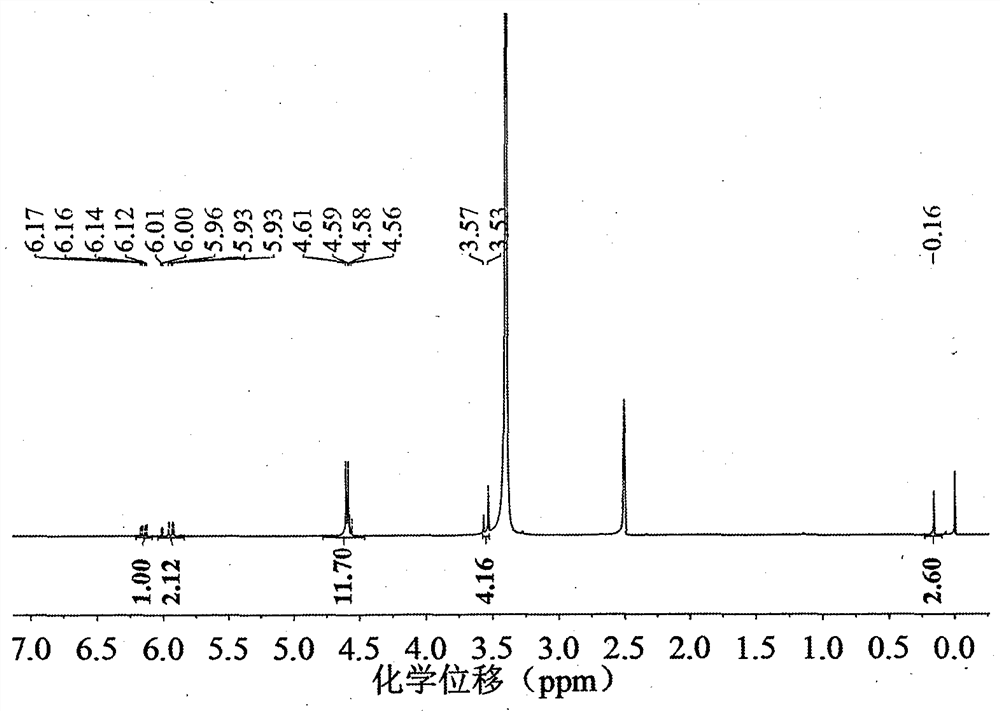

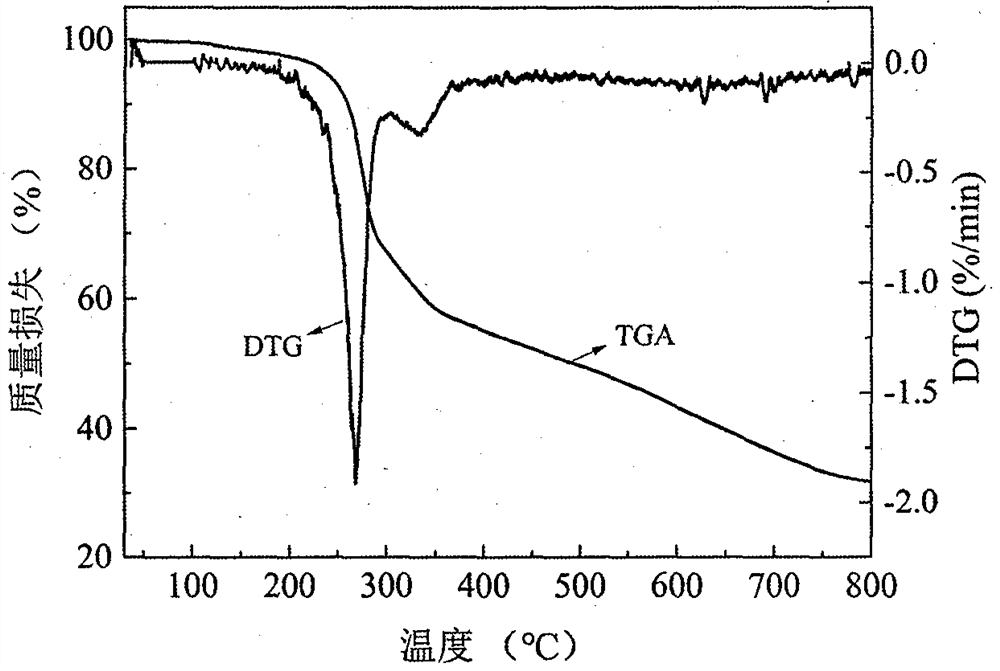

Method used

Image

Examples

Embodiment 1

[0041] Example 1 In a 250ml three-necked flask equipped with a stirrer, a thermometer, a reflux condenser and connected with a drying tube and a hydrogen chloride absorbing device at the top, add 0.10mol (19.60g) of cage-like pentaerythritol thiophosphate and 100ml of diethyl Glycol dimethyl ether, under the protection of nitrogen, raise the temperature to 60°C, start to drop 0.05mol (7.05g) methylvinyl dichlorosilane, after the drop, gradually raise the temperature to 140°C, keep the temperature for 10h, cool to room temperature , filtered, washed with 60ml of water until pH = 6-7, and dried to obtain a white solid vinyl silicone cage phosphorothioate with a yield of 85.2%.

Embodiment 2

[0042] Example 2 In a 250ml three-necked flask equipped with a stirrer, a thermometer, a reflux condenser and connected with a drying tube and a hydrogen chloride absorbing device at the top, add 0.105mol (20.58g) cage pentaerythritol thiophosphate and 110ml benzyl Ether, under the protection of nitrogen, the temperature was raised to 60 ° C, and 0.05 mol (7.05 g) of methyl vinyl dichlorosilane was added dropwise. 60ml of water was washed to pH = 6-7, and dried to obtain a white solid vinyl silicone cage phosphorothioate with a yield of 87.0%.

Embodiment 3

[0043] Example 3 In a 250ml three-necked flask equipped with a stirrer, a thermometer, a reflux condenser and connected with a drying tube and a hydrogen chloride absorbing device at the top, add 0.110mol (21.56g) cage-like pentaerythritol thiophosphate and 120ml tetrachlorohydrin Ethane, under the protection of nitrogen, heat up to 60°C, start to drop 0.05mol (7.05g) of methylvinyldichlorosilane, after dropping, gradually raise the temperature to 120°C, keep the temperature for 12h, cool to room temperature, filter, Wash with 70ml of water until pH = 6-7, and dry to obtain white solid vinyl organosilicon cage phosphorothioate with a yield of 90.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com