Reactive organosilicon flame retardant allyl trisilyl silicate compound and preparation method thereof

A technology of allyl trisilacol silicate and allyl silicate trisilacol, which is applied in the field of reaction type organosilicon flame retardant allyl silicate trisilacol ester compound and its preparation field, It can solve the problems of escaping, decomposition and affecting material properties, and achieve the effects of good carbon formation, anti-melting and dripping, high silicon content and high flame retardant efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

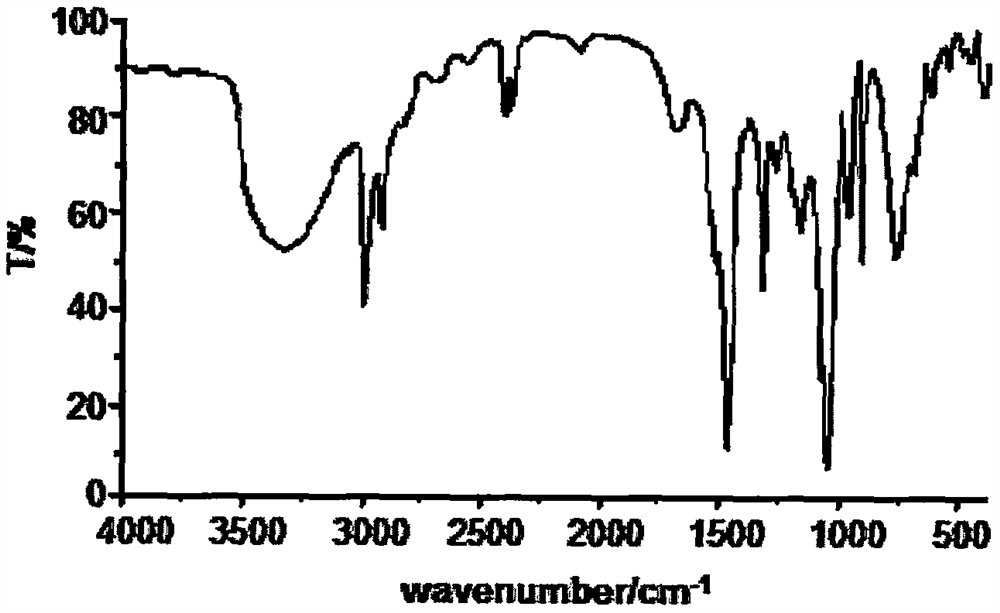

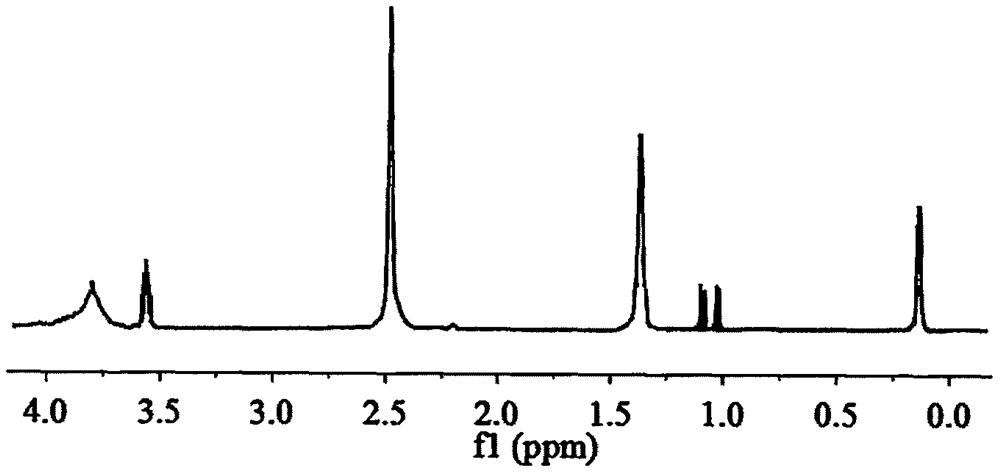

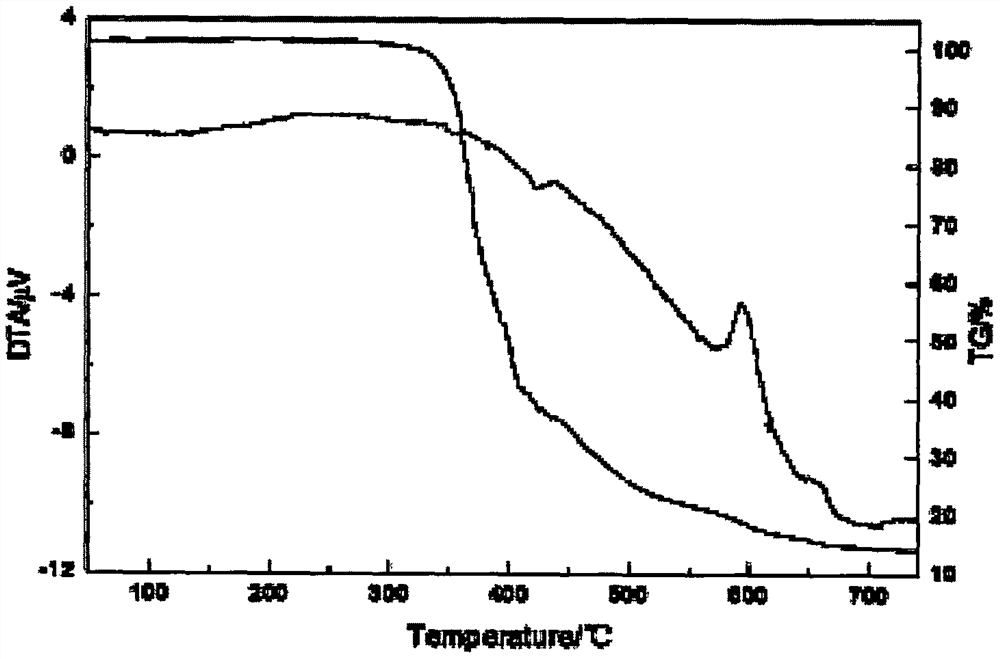

Embodiment 1

[0030] Example 1 In a 250ml three-necked flask equipped with a stirrer, a thermometer, a reflux condenser and a drying tube and a hydrogen chloride absorption device connected to the upper mouth, 0.15mol (26.40g) pentaerythritol methylsilicate and 130ml ethylene glycol were added Diethyl ether, under the protection of nitrogen, heat up to 60℃, start to add 0.05mol (8.78g) allyltrichlorosilane dropwise, after dripping, reflux and gradually heat up to 120℃, keep the temperature for 11h, and bind acid with triethylamine The agent is adjusted to pH=6.5-8, cooled to 25°C, filtered, washed with 70ml of cold water, and dried to obtain a white solid allyl trisilicate, and its decomposition temperature: 350±5°C, density (25 ℃): 1.384g / cm 3 The yield was 85.3%.

Embodiment 2

[0031] Example 2 In a 250ml three-necked flask equipped with a stirrer, thermometer, reflux condenser and connected to the upper mouth with a drying tube and hydrogen chloride absorption device, 0.155mol (27.28g) pentaerythritol methylsilicate and 100ml tetrachloroethane were added Alkane, under the protection of nitrogen, the temperature is raised to 60℃, and 0.05mol (8.78g) allyltrichlorosilane is added dropwise. After the dripping, the reflux is gradually heated to 130℃, the temperature is kept for 12h, and the acid binding agent is adjusted to pH=6.5-8, cooling to 25°C, filtering, washing with 70ml cold water, and drying to obtain white solid trisilicosan allylsilicate. Its decomposition temperature: 350±5°C, density (25°C): 1.384g / cm 3 The yield was 89.2%.

Embodiment 3

[0032] Example 3 In a 250ml three-necked flask equipped with a stirrer, a thermometer, a reflux condenser and a drying tube and a hydrogen chloride absorption device connected to the upper mouth, 0.16mol (28.40g) pentaerythritol methylsilicate and 100ml diethylene were added Dimethyl ethoxylate, under the protection of nitrogen, heat up to 60℃, start adding 0.05mol (8.78g) allyl trichlorosilane dropwise, after dripping, reflux and gradually heat up to 140℃, keep the temperature for 13h, use triethylamine The acid binding agent is adjusted to pH=6.5-8, cooled to 25℃, filtered, washed with 70ml cold water, and dried to obtain white solid trisilicone allylsilicate. Its decomposition temperature: 350±5℃, density (25℃): 1.384g / cm 3 The yield was 92.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com