Preparation method of flame retardant bisphosphoryl caged phosphate compound

A bisphosphoryl caged phosphate compound technology, which is applied in the field of preparation of organic phosphine flame retardant bisphosphoryl caged phosphate compounds, can solve problems such as restrictions on the use of halogenated flame retardants, and achieve cage ring structure symmetry Good performance, high flame retardant efficiency, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

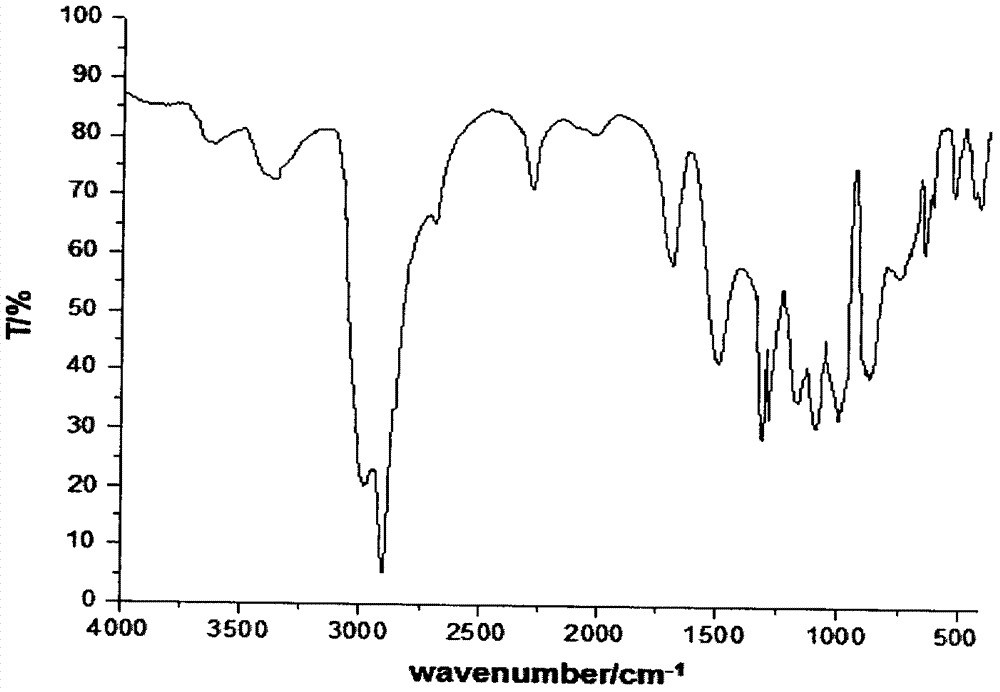

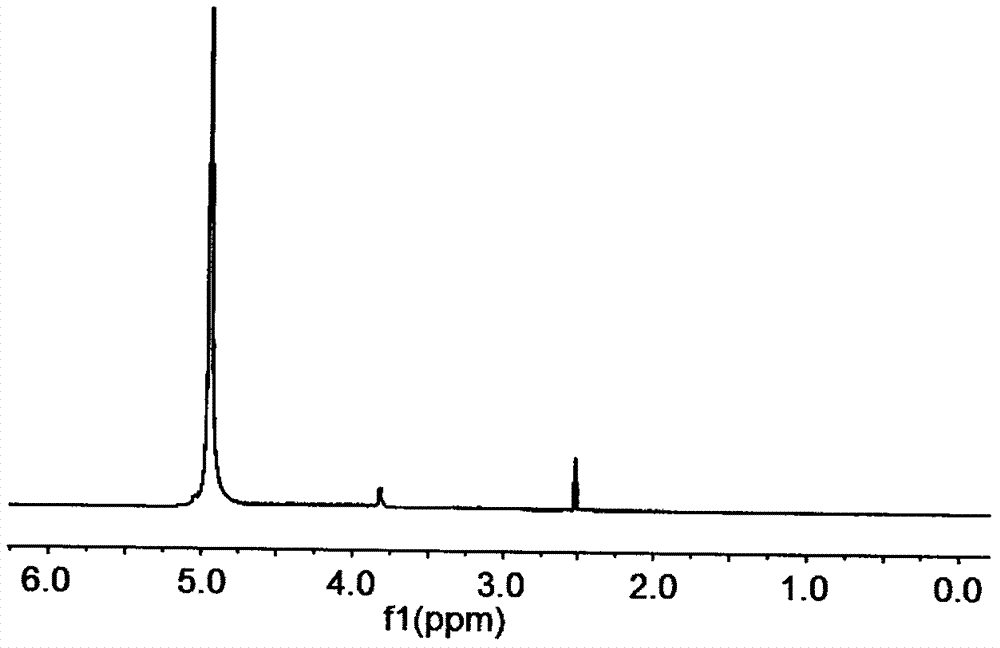

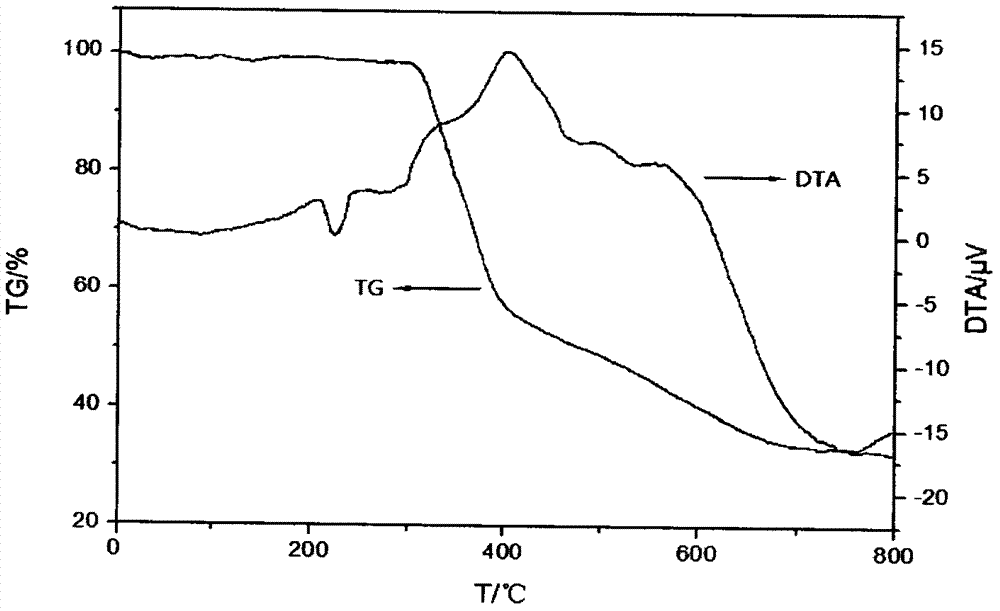

Embodiment 1

[0026] Example 1 In a 100ml four-necked flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and a hydrogen chloride absorption device connected to the upper mouth of the condenser, the air in the bottle was exhausted with nitrogen, and 30ml of dioxane was added, 14.00 g (0.1mol) trishydroxymethylphosphine oxide, cooled to below 10°C, add 15.33g (0.1mol) phosphorus oxychloride dropwise under stirring, make it fully mixed, heat up to 25°C, hydrogen chloride begins to be released, heat up Keep warm at 40°C for 2h, then raise the temperature to 100°C and keep warm for 4h, wait until no hydrogen chloride is released, remove dioxane by distillation under reduced pressure (for recycling), then add 50ml of ice water, add 5% sodium carbonate solution dropwise under stirring , the pH of the reaction system=7, the product solid was dispersed in water, filtered, the filter cake was rinsed with 10ml ice water, compacted and drained, the filter cake was vacuum-dr...

Embodiment 2

[0027] Embodiment 2 In the 100ml four-necked flask that stirrer, thermometer, high-efficiency reflux condensing tube are equipped with and being connected with hydrogen chloride absorption device on the condensing tube upper mouth, drive away the air in the bottle with nitrogen, add 40ml propionitrile, 14.00g ( 0.1mol) trishydroxymethyl phosphine oxide, cooled to below 10°C, add 15.33g (0.1mol) phosphorus oxychloride dropwise under stirring, make it fully mixed, heat up to 25°C, hydrogen chloride begins to be released, heat up to 40 ℃ for 2 hours, and then heated to 95 ℃ for 5 hours. After no hydrogen chloride is released, propionitrile is removed by distillation under reduced pressure (recycled), and then 45ml of ice water is added. With stirring, 5% sodium carbonate solution is added dropwise to make the reaction system pH=7, the product solid was dispersed in water, filtered, the filter cake was rinsed with 10ml of ice water, compacted and drained, and the filter cake was va...

Embodiment 3

[0028] Example 3 In a 150ml four-neck flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and a hydrogen chloride absorption device connected to the upper mouth of the condenser, the air in the bottle was exhausted with nitrogen, and 50ml of dichloroethane was added, 14.00 g (0.1mol) trishydroxymethylphosphine oxide, cooled to below 10°C, add 15.33g (0.1mol) phosphorus oxychloride dropwise under stirring, make it fully mixed, heat up to 25°C, hydrogen chloride begins to be released, heat up Keep warm at 40°C for 2h, then raise the temperature to 85°C and keep warm for 6h. After no hydrogen chloride is released, dichloroethane is removed by distillation under reduced pressure (recycled), then add 55ml of ice water, and add 5% sodium carbonate solution dropwise under stirring. , the pH of the reaction system=7, the product solid was dispersed in water, filtered, the filter cake was rinsed with 10ml of ice water, compacted and drained, the filter cake ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com