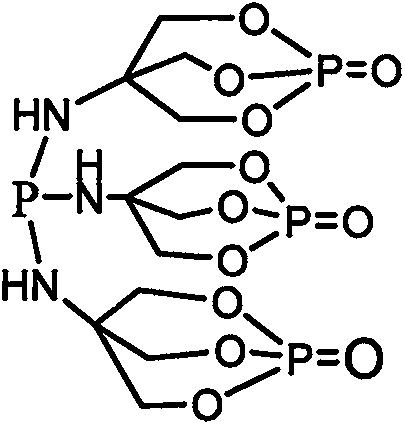

Fire retardant phosphinous-(N, N', N''-tri-cage phosphate) triamine compound, and preparation method thereof

A technology of flame retardant phosphorous acid and tricage phosphate, which is applied in the field of N, can solve problems such as restrictions on the use of halogenated flame retardants, and achieve good phosphorus and nitrogen synergistic flame retardant effects, high phosphorus content, and good compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

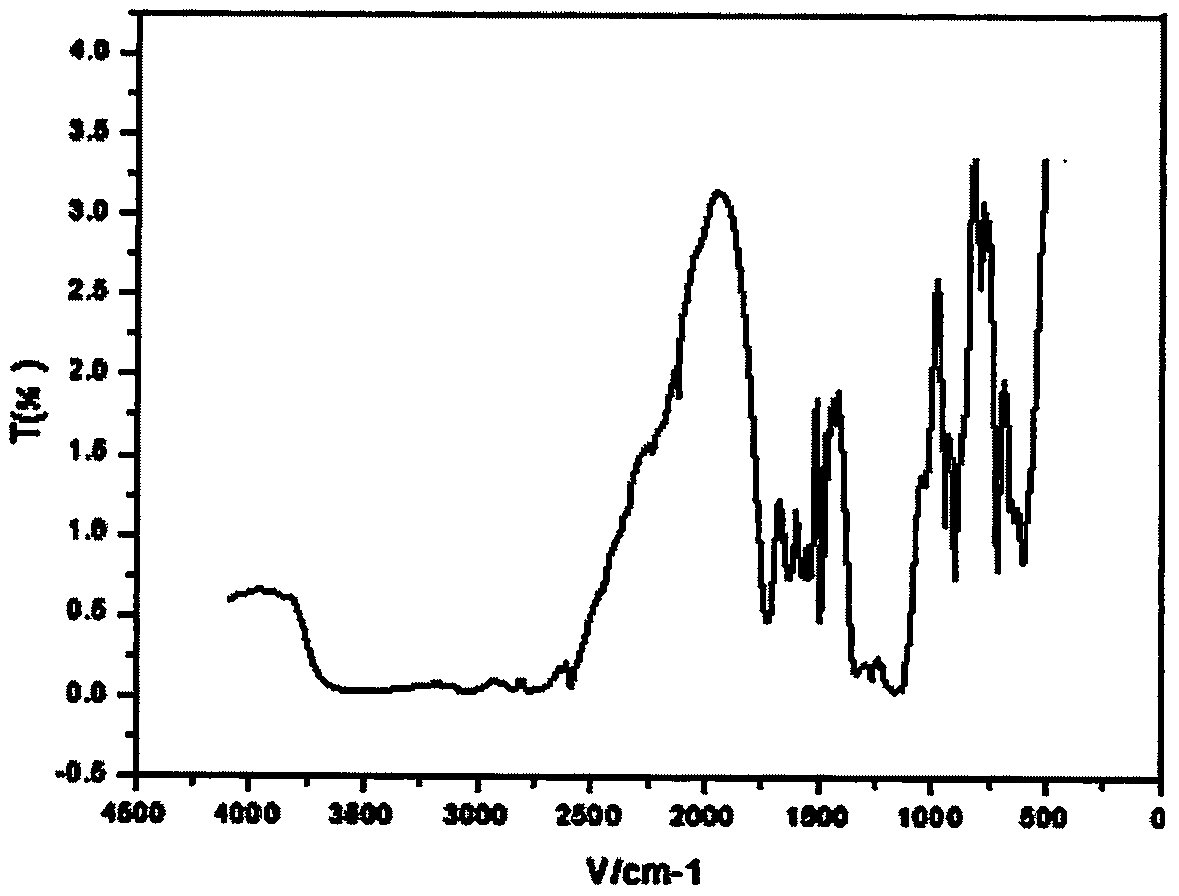

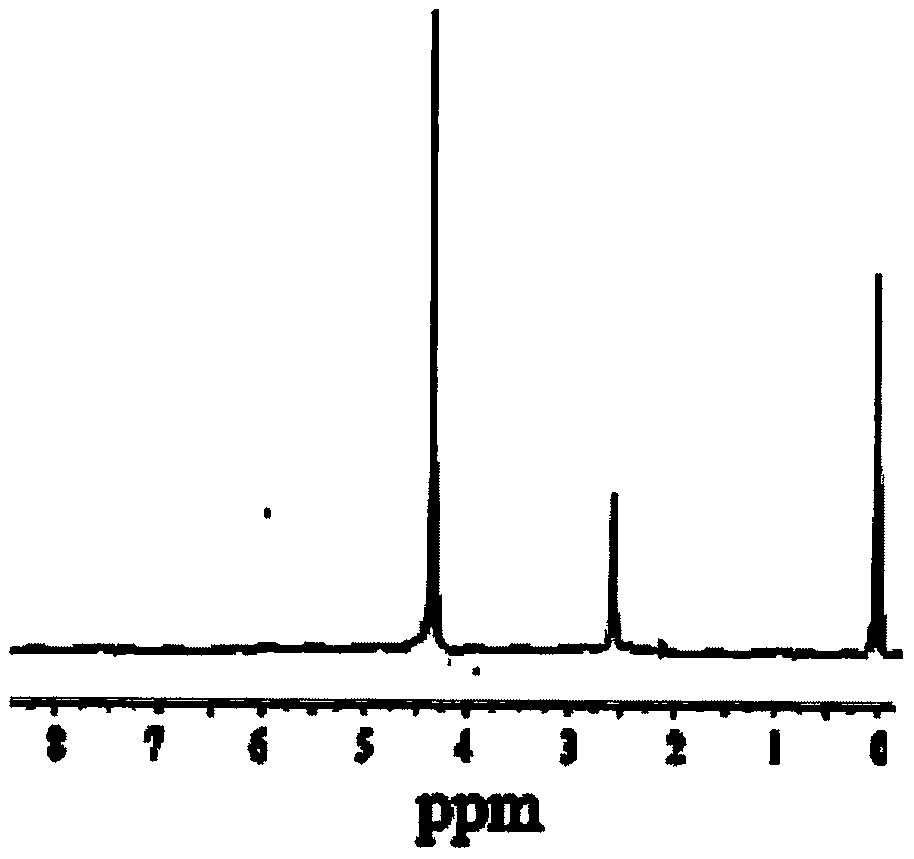

[0027] Example 1 In a 250ml four-neck flask equipped with a stirring device, dropping funnel, thermometer, and a high-efficiency reflux condenser connected to a drying tube, add 100ml of tetrachloroethane, 4.95g of caged phosphate amine and 3.03g of triethylamine , use nitrogen to drive out the air in the bottle, add 1.38g of phosphorus trichloride dropwise into the four-necked bottle at 10°C for about 1 hour, control the reaction temperature at 10°C-20°C, and raise the temperature to 100°C after the dropwise addition Insulated for 3 hours, then cooled, filtered, and vacuum-dried to obtain a solid mixture of a yellow product and triethylamine hydrochloride. The solid mixture was dissolved with 60ml of dimethyl sulfoxide, filtered, and the filtrate was evaporated to dryness to obtain the target product phosphorous acid-(N, N', N"-three cage phosphate) triamine, the yield was 89.4%, and the decomposition temperature was 261°C .

Embodiment 2

[0028] Example 2 In a 250ml four-neck flask equipped with a stirring device, dropping funnel, thermometer, and high-efficiency reflux condenser connected to a drying tube, add 80ml of dioxane, 4.95g of caged phosphate amine and 3.03g of triethylamine , use nitrogen to drive out the air in the bottle, and drop 1.38g of phosphorus trichloride into the four-necked bottle at 10°C for about 1 hour, control the reaction temperature at 10°C-20°C, and raise the temperature to 90°C after the addition is completed Insulated for 3 hours, then cooled, filtered, and vacuum-dried to obtain a solid mixture of a yellow product and triethylamine hydrochloride. The solid mixture was dissolved with 70ml of dimethyl sulfoxide, filtered, and the filtrate was evaporated to dryness to obtain the target product phosphorous acid-(N, N', N"-three cage phosphate) triamine, the yield was 90.1%, and the decomposition temperature was 261°C .

Embodiment 3

[0029] Example 3 In a 250ml four-neck flask with a stirring device, dropping funnel, thermometer, and high-efficiency reflux condenser connected to a drying tube, add 80ml of acetonitrile, 4.95g of caged phosphate amine and 3.03g of triethylamine, and use nitrogen Drive out the air in the bottle, add 1.38g of phosphorus trichloride dropwise into the four-necked bottle at 10°C for about 1 hour, control the reaction temperature at 10°C-20°C, and raise the temperature to 80°C for 4 hours after the dropwise addition , then cooled, filtered, and vacuum-dried to obtain a solid mixture of a yellow product and triethylamine hydrochloride. The solid mixture was dissolved with 80ml of dimethyl sulfoxide, filtered, and the filtrate was evaporated to dryness to obtain the target product phosphorous acid-(N, N', N"-three cage phosphate) triamine, the yield was 91.0%, and the decomposition temperature was 261°C .

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com