A high-precision method for measuring the structural dimension deformation of spacecraft

A technology for the deformation of the structure and size of a spacecraft, which is applied to measurement devices, instruments, space navigation equipment, etc., can solve the problems of changing the refractive index of the air, increasing the error, and failing to achieve the accuracy of the sensor, so as to improve the accuracy, reduce the development cost, The effect of good production and scientific research benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a high-precision spacecraft structural dimension deformation measurement method, which adopts the cyclic loading method to perform high-precision deformation measurement, simulates the real pressure and temperature environment of the spacecraft in orbit, and uses the deformation time domain signal preprocessing and The spectral transformation method eliminates the measurement system error, and effectively improves the accuracy of the structural dimension deformation measurement.

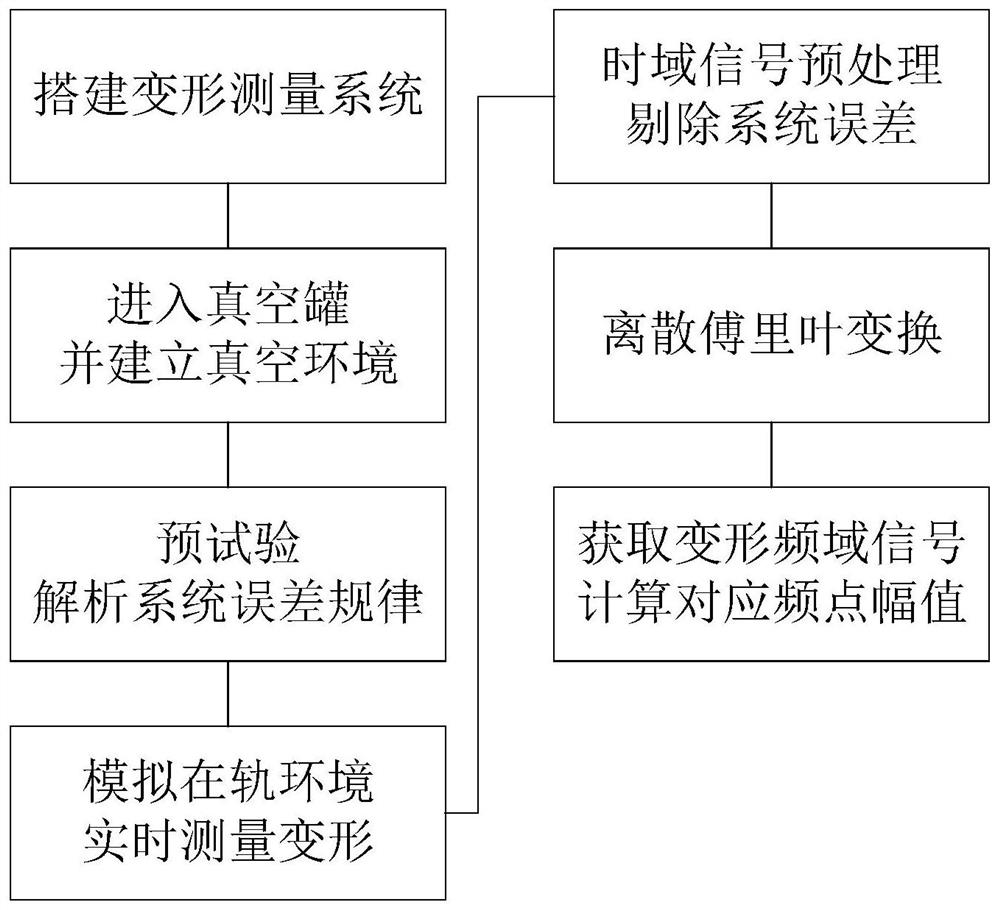

[0038] like figure 1 As shown, the deformation measurement method includes the following steps:

[0039] Step 1. Build a deformation measurement system;

[0040] The deformation measurement system includes: a sensor fixing tool and a high-precision optical displacement sensor (such as a laser displacement sensor), and the optical displacement sensor is installed on the spacecraft through the sensor fixing tool to form a deformation measurement system;

[0041] In ord...

Embodiment 2

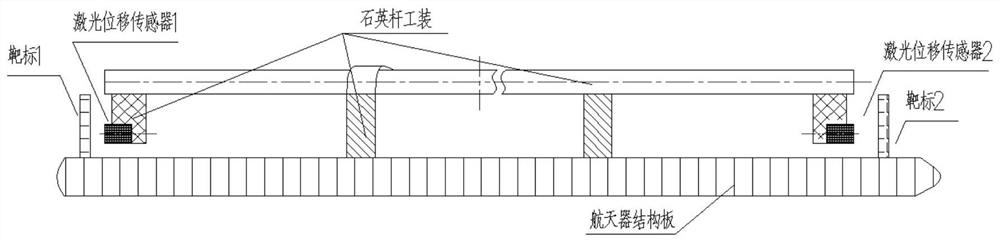

[0065] Step 1. Build a deformation measurement system based on a laser displacement sensor and a low-expansion quartz tool;

[0066] like figure 2 As shown, two laser displacement sensors are erected on the spacecraft structural plate through a quartz rod tooling, so that the two laser displacement sensors are respectively opposite to the targets at both ends of the spacecraft structural plate;

[0067] Step 2, carrying out the deformation measurement test in the vacuum tank, wherein, the pressure of the control vacuum tank is less than 1E-2Pa;

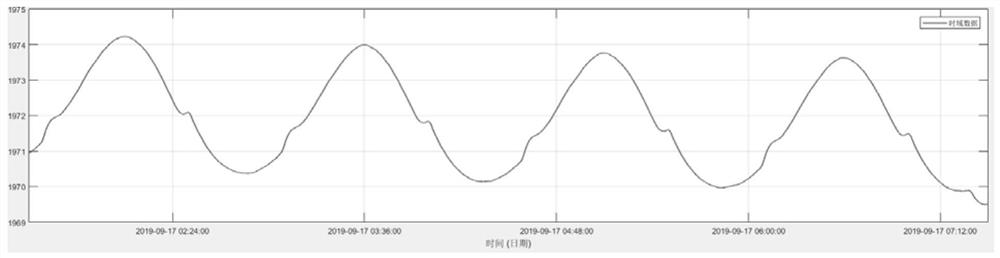

[0068] Step 3. The deformation measurement system is pre-tested in the vacuum tank with the spacecraft. The test time is 10 hours. During this period, the deformation measurement system continues to work. The measured result is the drift law of the deformation measurement system, which drifts monotonically and shows a convergence trend. , using a quadratic function to fit the drift law, the form of the quadratic function is:

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com