A lithium battery pack case for a communication base station

A technology for a lithium battery pack and a communication base station is applied in the field of lithium battery pack chassis, which can solve the problems of unsmooth air intake and reduced heat dissipation efficiency of the chassis, and achieve the effect of smooth air intake and efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

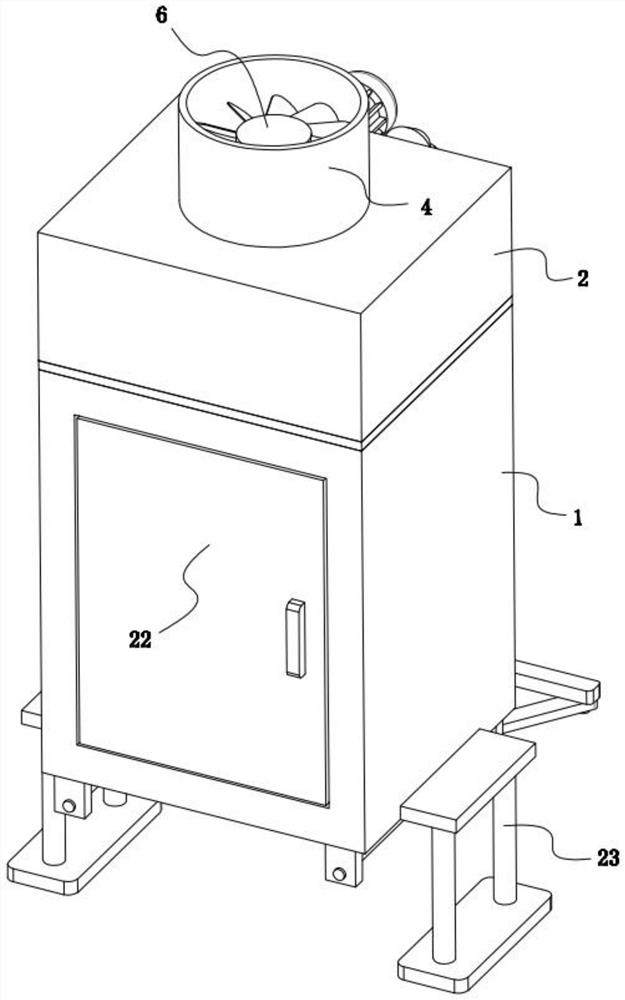

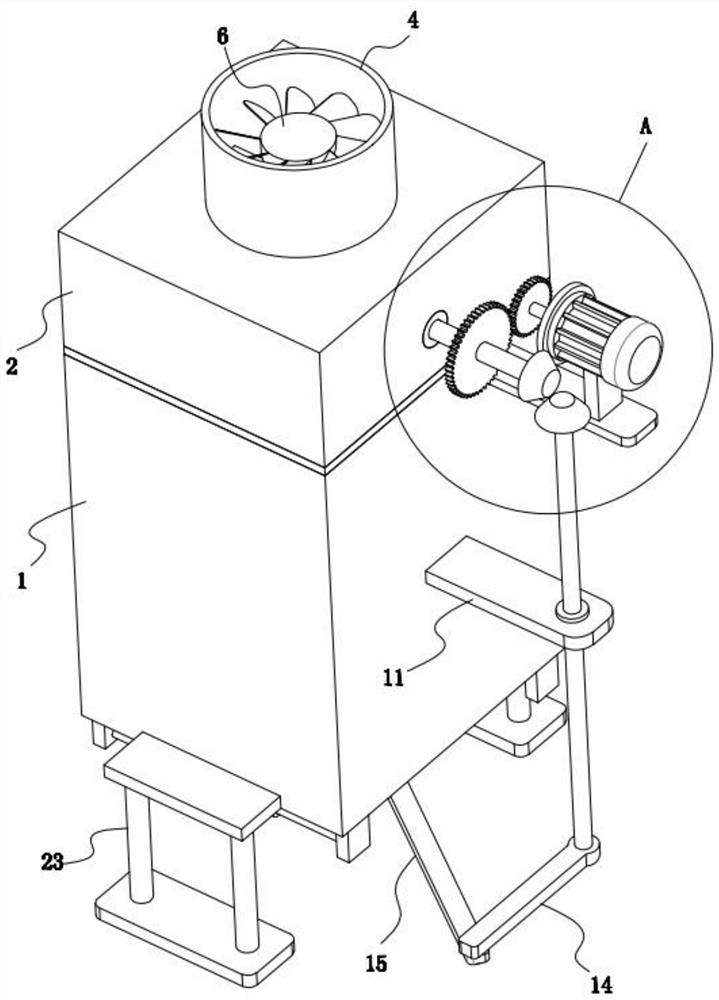

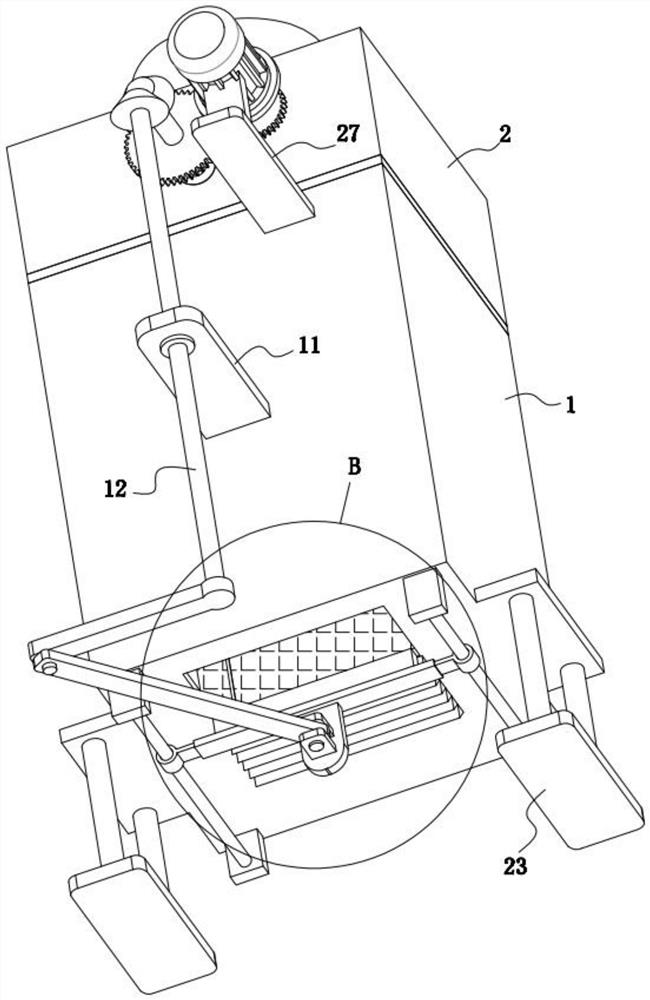

Embodiment 1

[0022] refer to Figure 1-8 , a lithium battery pack case for a communication base station, comprising a first case body 1, a movable door 22 is hingedly installed on the first case body 1, and two supporting legs correspondingly arranged are fixedly installed on the lower part of the outer wall of the first case body 1 23. The top of the first box body 1 is fixedly installed with a second box body 2 that communicates with the inside thereof, a filter grid 3 is arranged between the first box body 1 and the second box body 2, and the top surface of the second box body 2 is fixed A cylinder 4 that communicates with it is installed. The cylinder 4 is rotatably installed with a first rotating shaft 5 that is coaxially arranged with it. The top of the first rotating shaft 5 is fixedly installed with a fan blade 6. A fixed plate 11 is fixedly installed, and a third rotating shaft 12 arranged parallel to the first rotating shaft 5 is rotatably installed on the fixed plate 11. 12. Th...

Embodiment 2

[0028] refer to Figure 1-8 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that a scraper 21 corresponding to the movement trajectory of the brush 17 is provided on one side of the filter screen 18, and the scraper 21 is fixedly installed on the first box body 1 On the bottom surface, the scraper 21 is formed by a plurality of triangular prisms arranged at equal intervals, and the triangular prisms are all disposed toward the side away from the second rotating shaft 7 .

[0029] When the crank connecting rod mechanism drives the brush 17 to reciprocate in a straight line along the guide rod 19, when the brush 17 passes the scraper 21, the triangular prism on the scraper 21 will scrape off the impurities attached to the bristles of the brush 17. Therefore, it is avoided that the cleaning effect is deteriorated due to excessive impurities adhering to the brush 17 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com