Single-output-shaft liquid ring type vacuum pump internally provided with sliding bearing

A technology of liquid ring vacuum pump and sliding bearing, which is applied in the direction of rotary piston type/oscillating piston type pump components, rotary piston type pumps, parts of pumping devices for elastic fluid, etc., which can solve the problem of sealing performance and safety and reliability Poor performance, inconvenient installation and maintenance, large floor space, etc., to improve the sealing effect, save raw materials, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

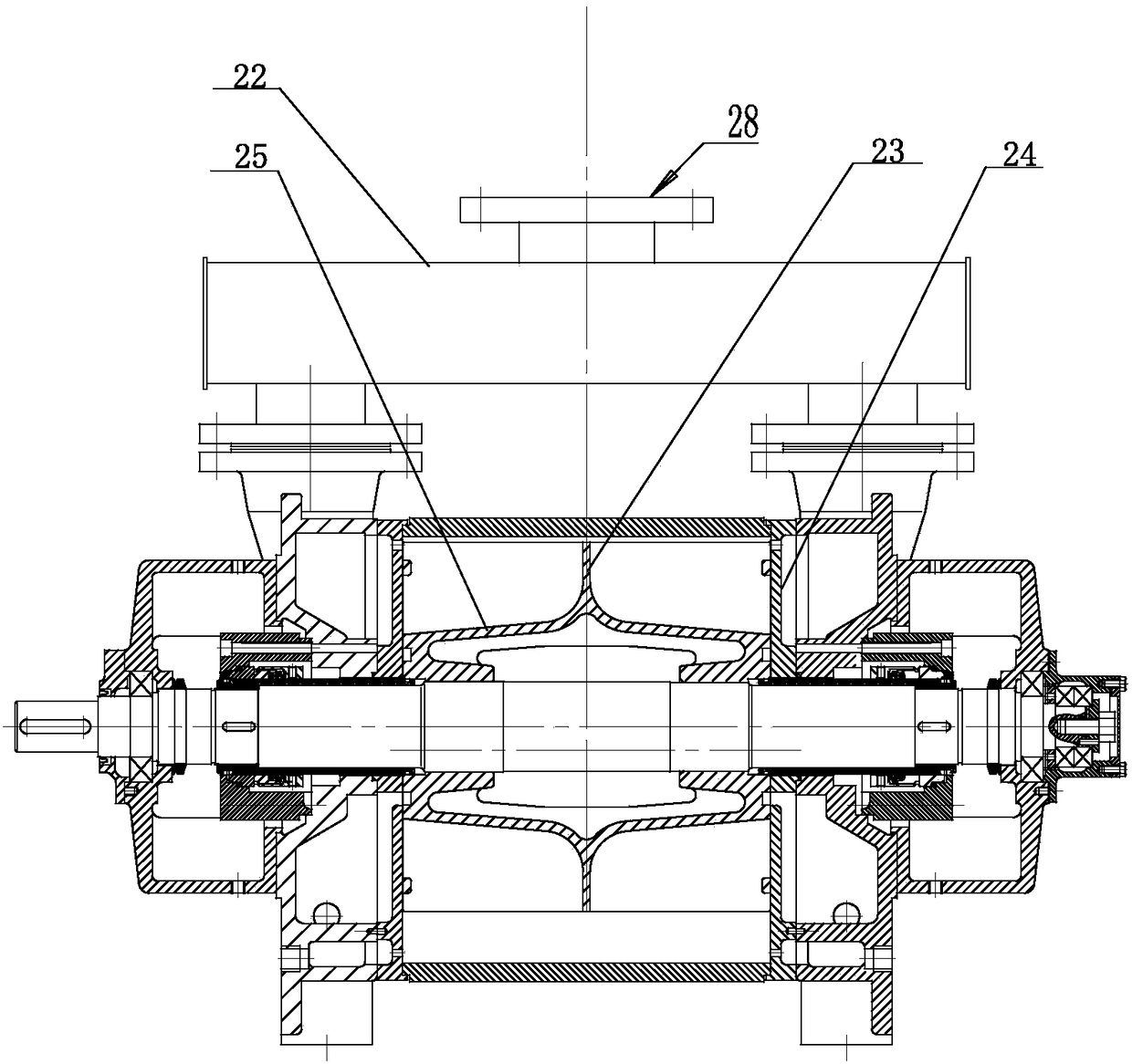

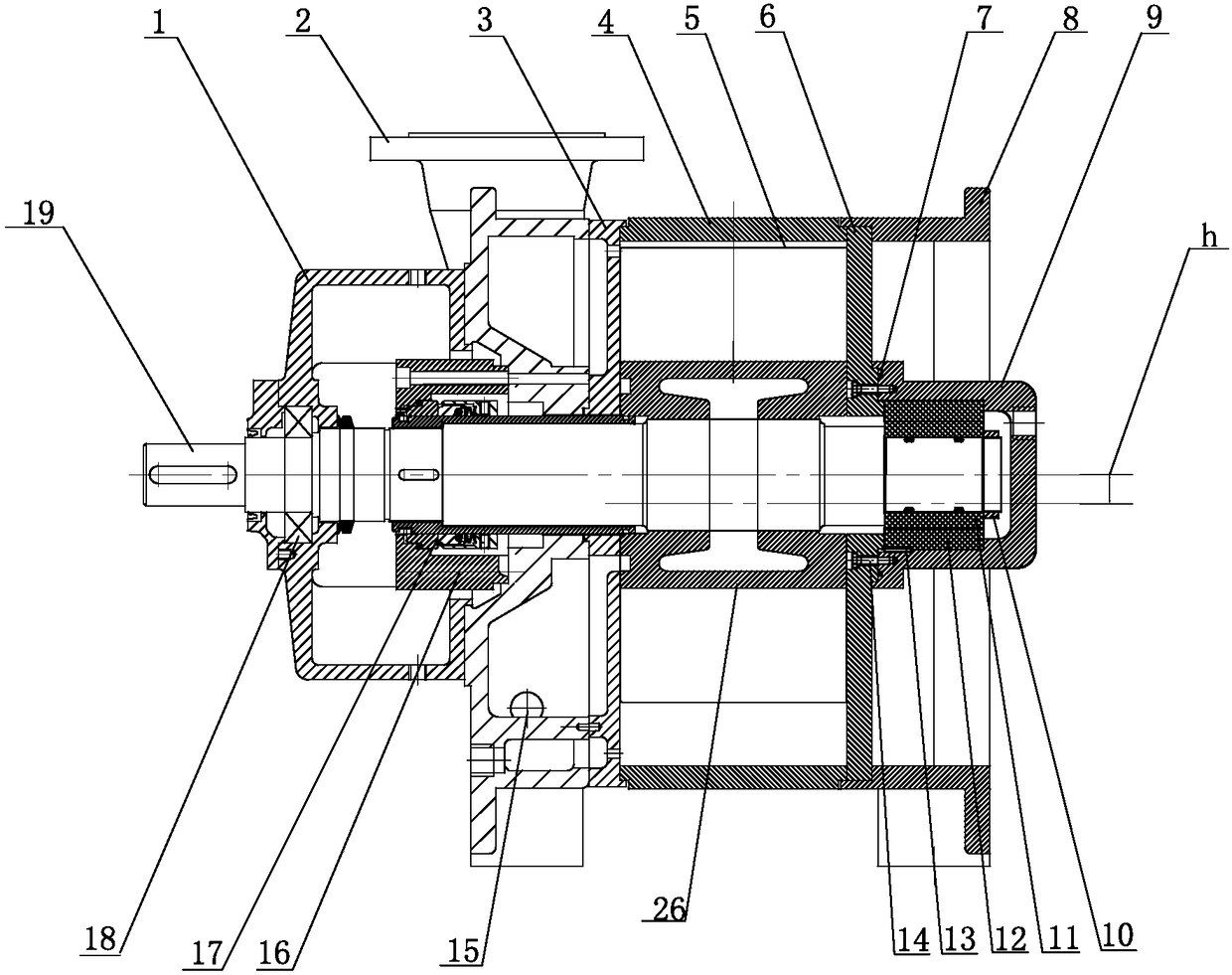

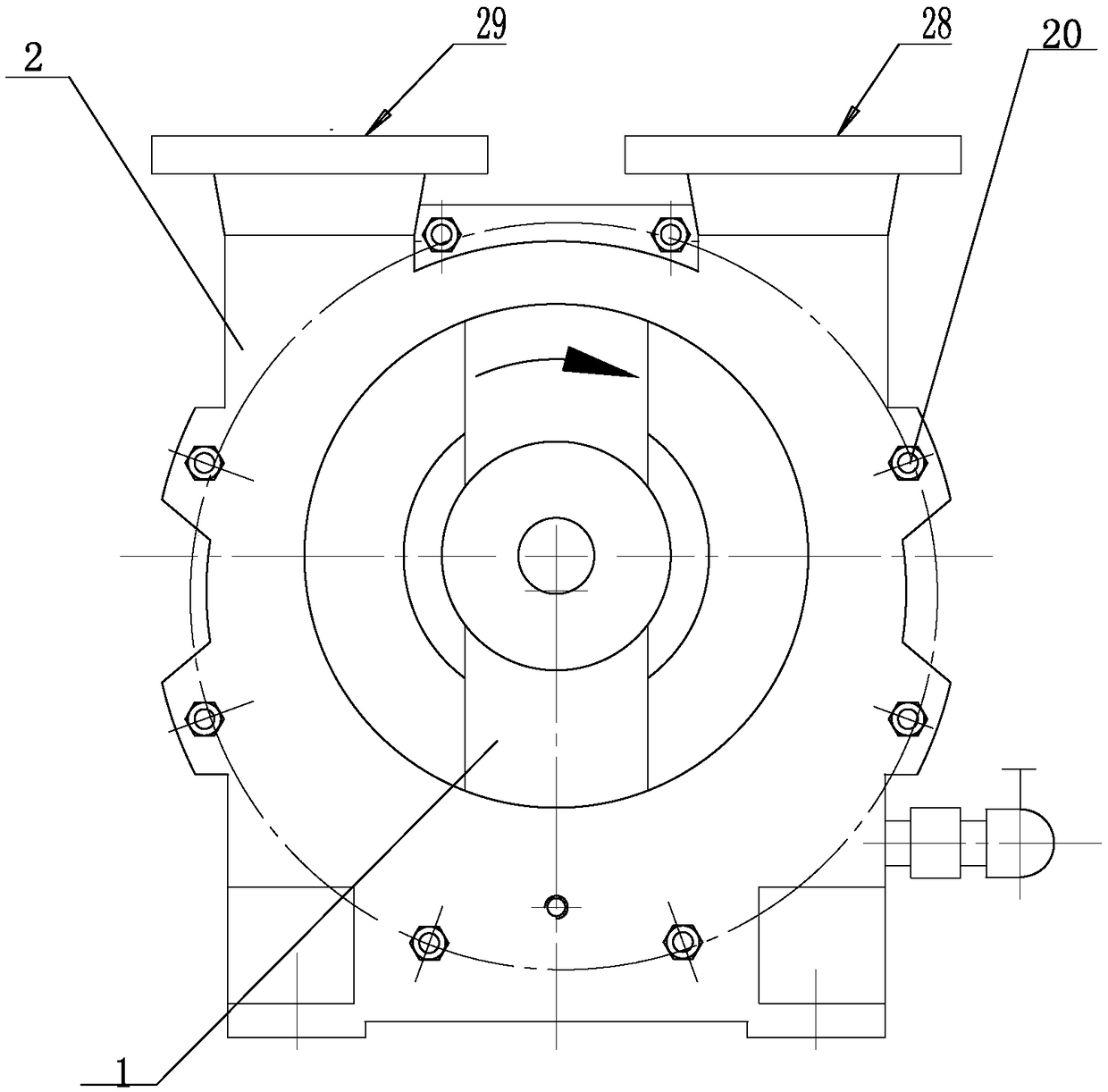

[0037] Such as Figure 1 to Figure 5 As shown, the single-outlet shaft liquid ring vacuum pump with built-in sliding bearings according to the present invention includes a pump body 4, a pump shaft 19 is provided through the pump body 4, and a distribution plate 3, a second A pump cover 2, a mechanical seal seat 16 and an external bearing seat 1, the first end of the pump shaft 19 runs through the distribution plate 3, the first pump cover 2, the mechanical seal seat 16 and the external bearing seat 1, and the second end of the pump shaft 19 The end is installed in a sliding bearing seat 9 with one end closed, and a second pump cover 8 is provided outside the sliding bearing seat 9, and a sealing cover 6 is provided between the second pump cover 8 and the pump body 4, and the pump shaft 19 runs through the sealing cover 6 set up. A liquid inlet is arranged on the first pump cover. The pump shaft 19 is connected to the outer bearing seat 1 through the rolling bearing 18, and ...

Embodiment 2

[0041] Such as Figure 1 to Figure 5 As shown, on the basis of Example 1, the sliding bearing outer sleeve 12 is a pressureless sintered ceramic sliding bearing outer sleeve; the sliding bearing inner sleeve 11 is a pressureless sintered ceramic sliding bearing inner sleeve. The sliding bearing outer sleeve 12 is fixedly connected to the sliding bearing seat 9 through positioning pins 13 ; the sliding bearing inner sleeve 11 is fixedly connected to the pump shaft 19 through a round nut 10 .

Embodiment 3

[0043] Such as Figure 1 to Figure 5As shown, on the basis of Embodiment 2, the impeller 5 is arranged on the pump shaft 19 in the pump body 4, and the impeller 5 includes a straight cylindrical impeller hub 26 arranged on the pump shaft. The gap between the impeller 5 and the distribution disc 3 is 0.3-0.5mm. The gap between the impeller 5 and the sealing cover 6 is 0.3-0.5mm. There is an eccentricity h between the impeller and the pump body. The eccentricity h can be set according to conventional technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com