Mixing equipment for preparing cosmetics made of animal and plant extract and using method thereof

A technology of animal and plant extracts and mixing equipment, which is applied in the direction of chemical instruments and methods, mixers, chemical/physical processes, etc., and can solve the problems that volume equipment cannot be pre-grinded and the mixing effect is not good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

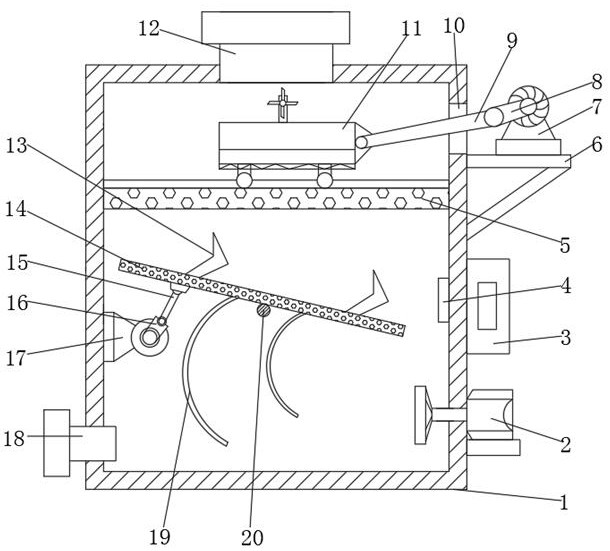

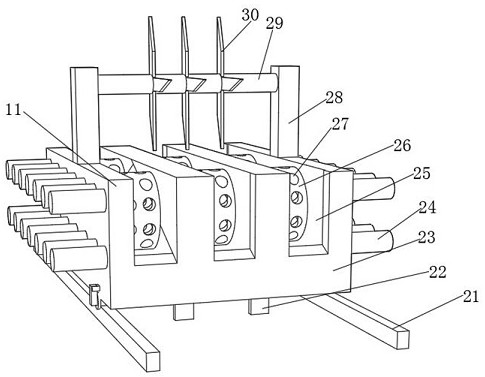

[0034] refer to Figure 1-3 , a kind of mixing equipment for the preparation of animal and plant extract cosmetics, comprising a box body 1, a feed pipe 12 is welded on the upper surface of the box body 1, and a discharge pipe 18 is welded on one side of the outer wall of the box body 1, and the box body One side of the outer wall of 1 is fixed with a fixed frame 6 by bolts, and one side of the inner wall of the box body 1 is fixed with a filter screen 5 by bolts, and the top of the filter screen 5 is provided with an auxiliary device 11, and the top of the fixed frame 6 passes through The bolt is fixed with the first motor 7, and one end of the output shaft of the first motor 7 is fixed with the first transmission rod 8 by the bolt, and one end of the first transmission rod 8 is rotatably connected with the second transmission rod 9, and one end of the second transmission rod 9 Connected with the auxiliary device 11, a connection port 10 is opened on one side of the box body ...

Embodiment 2

[0046] refer to Figure 1-3 , a kind of mixing equipment for the preparation of animal and plant extract cosmetics, comprising a box body 1, a feed pipe 12 is welded on the upper surface of the box body 1, and a discharge pipe 18 is welded on one side of the outer wall of the box body 1, and the box body One side of the outer wall of 1 is fixed with a fixed frame 6 by bolts, and one side of the inner wall of the box body 1 is fixed with a filter screen 5 by bolts, and the top of the filter screen 5 is provided with an auxiliary device 11, and the top of the fixed frame 6 passes through The bolt is fixed with the first motor 7, and one end of the output shaft of the first motor 7 is fixed with the first transmission rod 8 by the bolt, and one end of the first transmission rod 8 is rotatably connected with the second transmission rod 9, and one end of the second transmission rod 9 Connected with the auxiliary device 11, a connection port 10 is opened on one side of the box body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com