High-power filter core with function of sterilization

A high-power, filter element technology, applied in fixed filter element filters, sterilization/microdynamic water/sewage treatment, filtration and separation, etc., can solve the problems of high cost, easy scrapping of filter elements, inconvenient use, etc., and achieve processing Low cost, increased rigidity, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

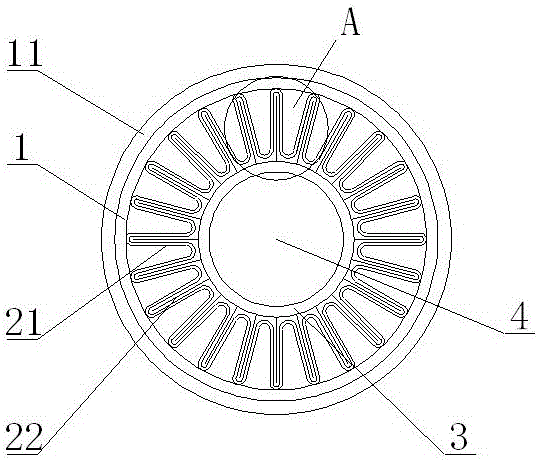

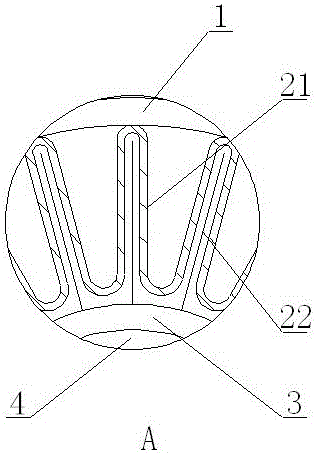

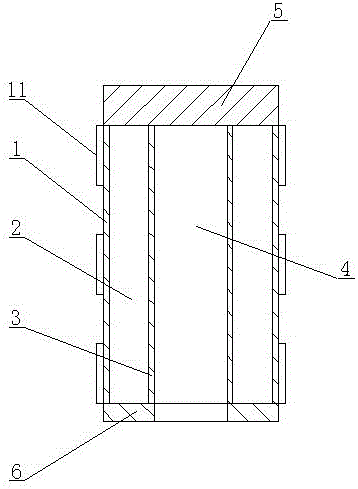

[0027] Such as figure 1 , figure 2 , image 3 As shown, in this embodiment, a high-power filter element with bactericidal function includes A filter layer 1, B filter layer 2 arranged in A filter layer 1, and water outlet 4 arranged in B filter layer 2, B The filter layer 2 is provided with a filter core 21, the filter core 21 is circularly arranged in a wave shape, and the distance between the maximum diameter and the minimum diameter of the filter core 21 is 5 to 15 times the thickness of the filter core 21, and the filter core 21 is The folded microporous filter element has the advantages of high filtration efficiency, easy folding, and high quality. In the present invention, it is convenient to fold into a wave shape and to be processed into a ring shape by hot-melt bonding. The manufacturing process is simple and the processing cost is low. Conducive to batch production, one end of A filter layer 1 is provided with sealing end cap 5, and the other end of A filter layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com