Anti-slip device for automobile part rack

A technology for auto parts and material racks, applied in tool storage devices, manufacturing tools, etc., can solve the problems of falling materials, difficult to take out, inconvenient take-out operations, etc., to prevent materials from falling, stable storage, and avoid inconvenient access. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

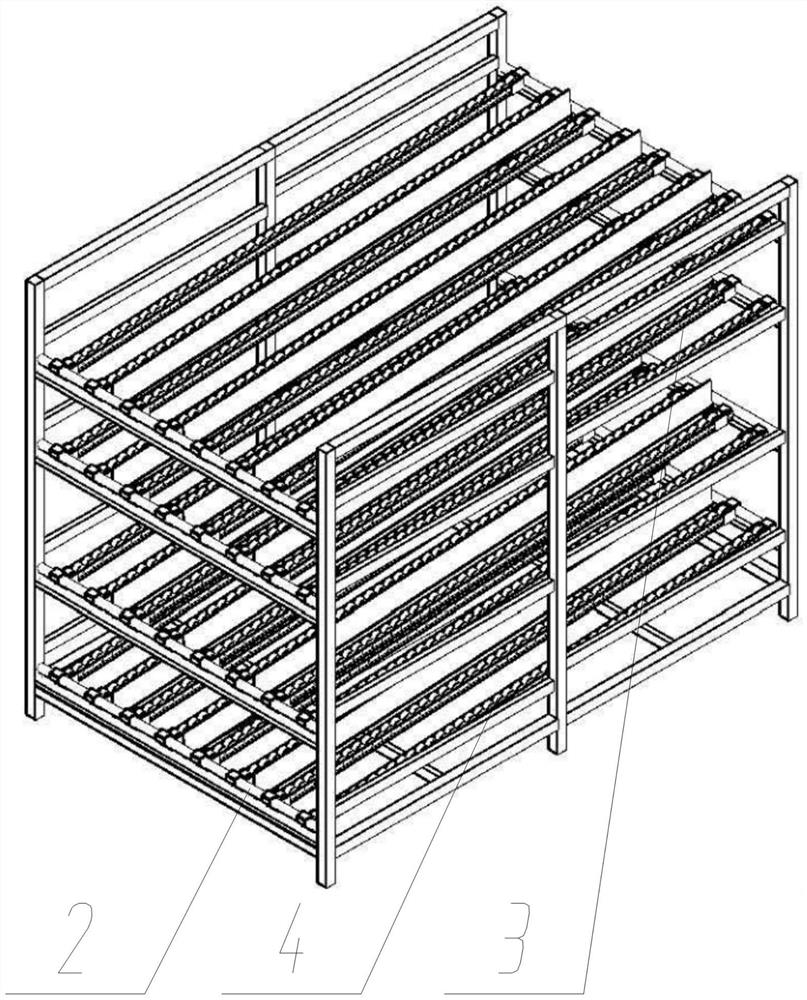

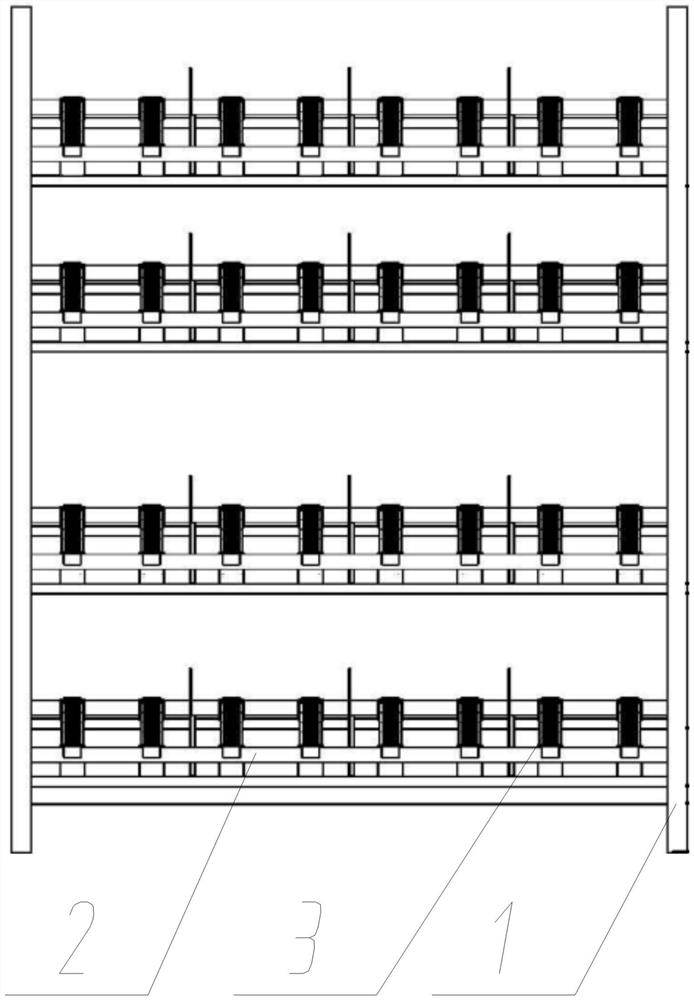

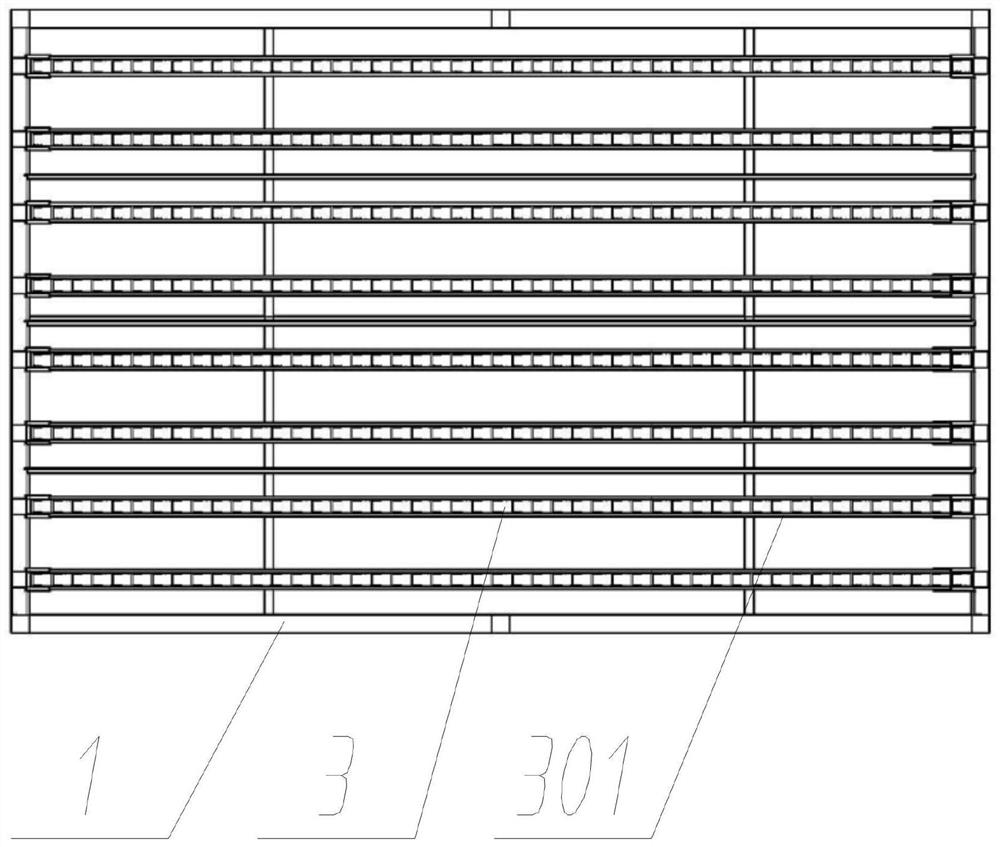

[0023] as attached figure 1 to attach Figure 4 Shown:

[0024] The invention provides an anti-slip device for auto parts racks, which includes a support body 1; four sets of cross bars 2 are fixedly connected to the front and back of the support body 1; Assembling the storage parts 3; the materials 4 are evenly arranged on the storage parts 3.

[0025] Wherein, the storage part 3 also includes a material baffle 301, the section of the storage part 3 is a U-shaped structure, and a group of material baffles 301 are fixedly connected to the left and right sides of the storage part 3. In use, through the storage part 3 Place the material 4, and block the material 4 through the material baffle 301 to prevent the material 4 from falling.

[0026] Among them, the stocking part 3 is provided with an inclination with a low front and a high rear. In use, the material 4 slides forward on the stocking part 3 under the influence of gravity, so that the material 4 on the stocking part 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com