Sand setting device for sewage treatment

A technology for sewage treatment and sand settling, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Pump and other problems to achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

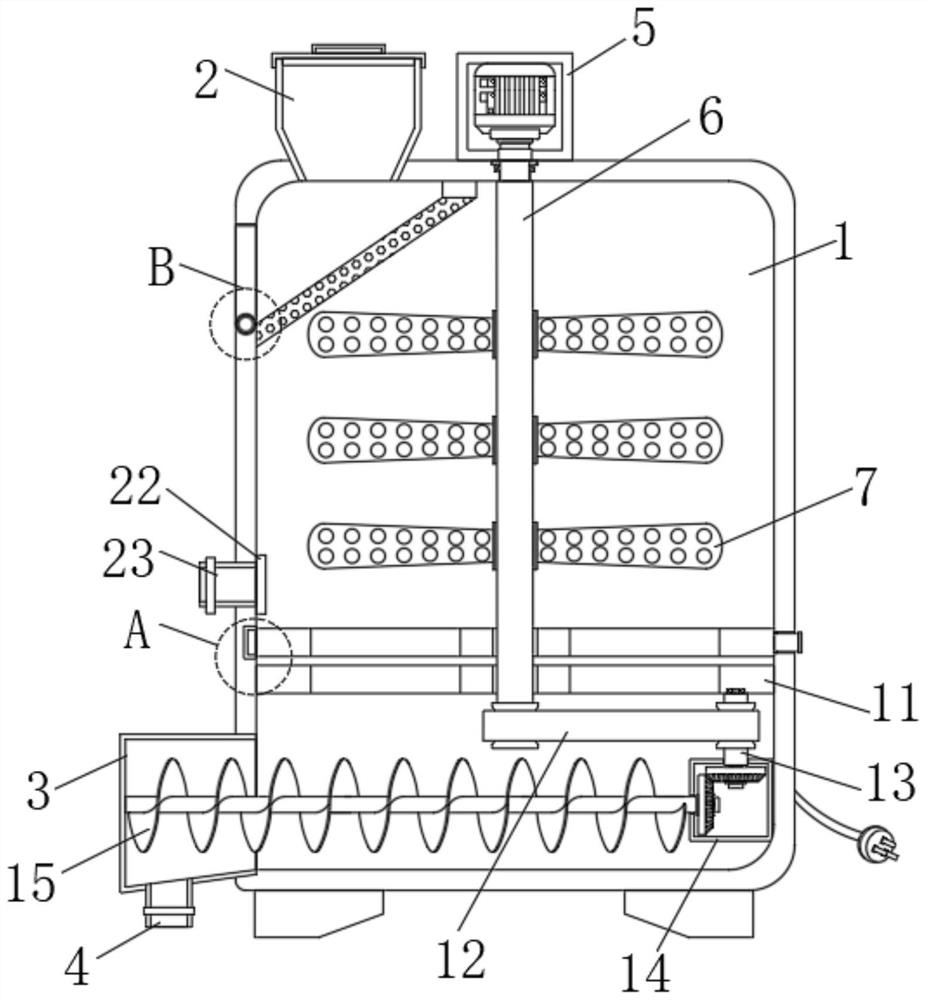

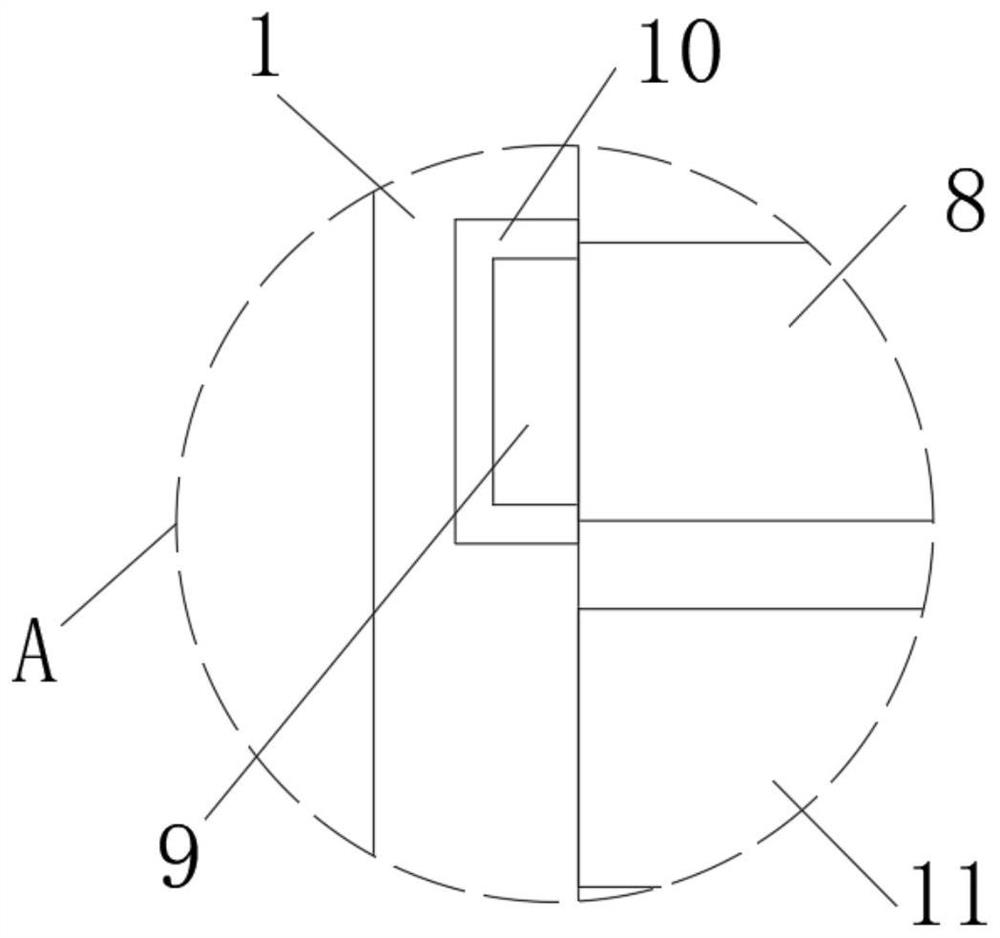

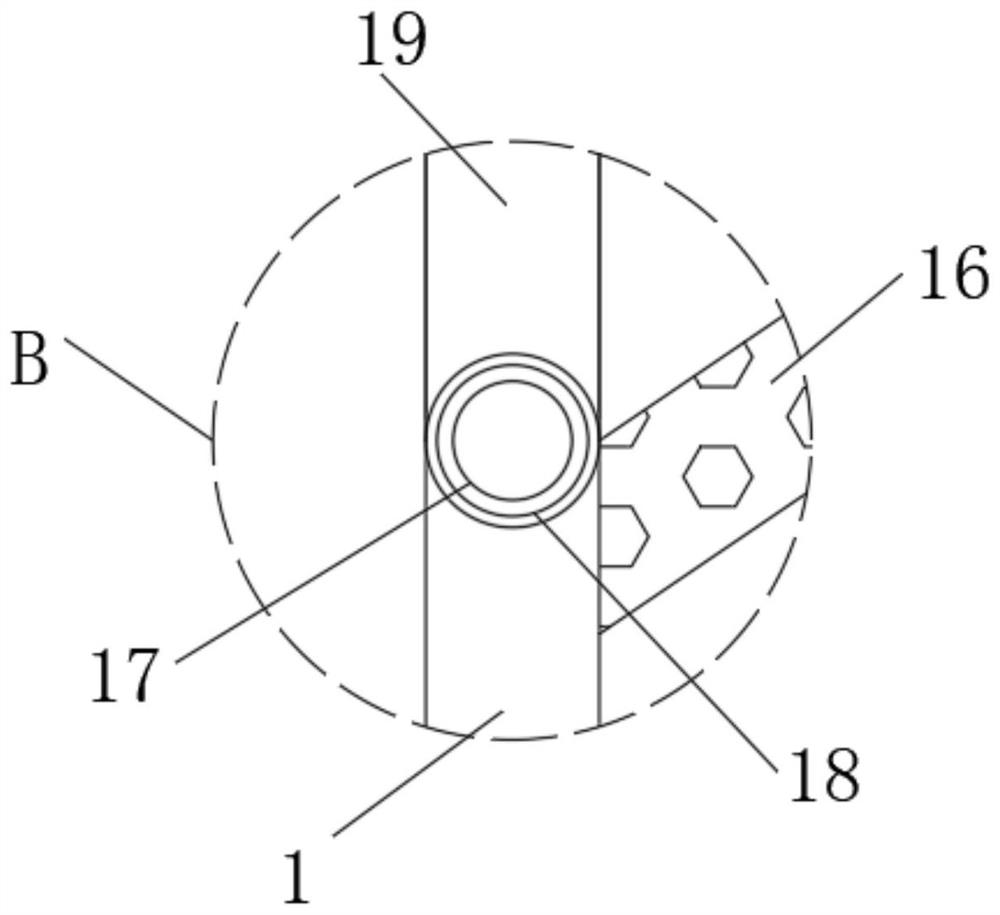

[0025] Such as Figure 1-5 As shown, a grit settling device for sewage treatment includes a grit settling box 1, a sand discharge box 3, a water inlet 2, a sand discharge port 4, a motor 5 and a stirring blade 7, and the bottom of the grit settling box 1 There is a sand discharge box 3, the top of the sand settling box 1 is provided with a water inlet 2, the lower side of the sand discharge box 3 is provided with a sand discharge port 4, and the top of the sand settling box 1 is fixedly installed with a motor 5, the motor The output end of 5 is fixedly connected with a rotating shaft 6, and the outer side of the rotating shaft 6 is fixedly connected with a stirring blade 7, and an openable sealing device is provided between the sand settling box 1 and the sand discharging box 3, when the sewage is stirred and treated When the sewage is stirred, the sealing device is closed; when the sewage is stirred and left still, the sealing device is opened, so that the sand particles fall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com