Lens, automobile lamp lens system and automobile

A lens and sawtooth technology, applied in the field of automobile headlamps, can solve problems such as chromatic dispersion, achieve the effect of eliminating chromatic dispersion, improving reddish or bluish, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

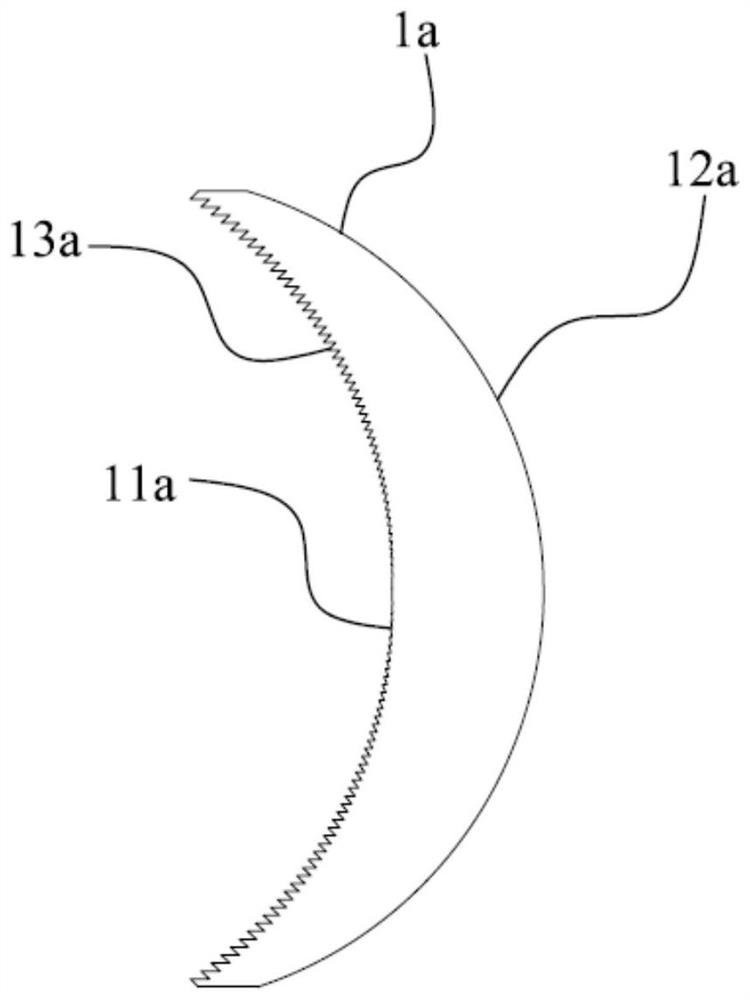

[0032] Such as figure 1 As shown, in the lens 1a provided by Embodiment 1 of the present invention, the cross-section of the lens 1a is meniscus-shaped, and the lens 1a includes a first surface 11a and a second surface 12a.

[0033] The first surface 11a is a binary surface, and the second surface 12a is a smooth surface.

[0034] The binary surface includes a base surface and a plurality of serrations 13a spaced apart from each other formed on the base surface.

[0035] In the lens 1a provided by Embodiment 1 of the present invention, since the dispersion coefficient of the smooth surface is a positive number, while the dispersion coefficient of the binary surface has nothing to do with the material, and the dispersion coefficient of the binary surface is a negative number, by setting the first surface 11a to two The element surface can make the dispersion coefficient of the binary surface and the dispersion coefficient of the smooth surface cancel each other, so as to elimi...

Embodiment 2

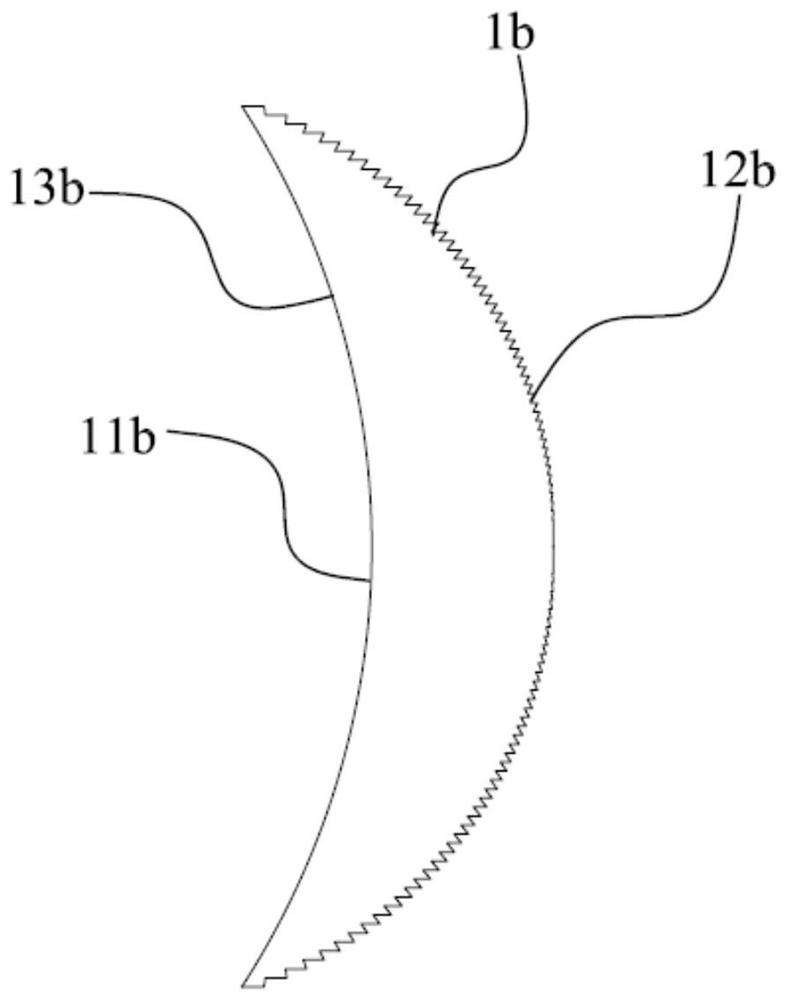

[0058] Such as figure 2 As shown, the difference between the lens 1b provided by Embodiment 2 of the present invention and Embodiment 1 is that the first surface 11b of the lens 1b is a smooth surface, and the second surface 12b of the lens 1b is a binary surface, so as to form the The lens 1b.

[0059] In the lens 1b provided by Embodiment 2 of the present invention, by setting the second surface 12b as a binary surface, the dispersion coefficient of the binary surface and the dispersion coefficient of the refracting surface can cancel each other, so as to eliminate the dispersion and improve the reddish or near cut-off line. Blue issue. In addition, since the size of the sawtooth 13b on the binary surface is nanoscale, it cannot be observed by human eyes and does not affect the appearance of the lens. Compared with the existing Fresnel lens, the lens 1b of the embodiment of the present invention has a The proportion of the working surface is relatively large, and the non-...

Embodiment 3

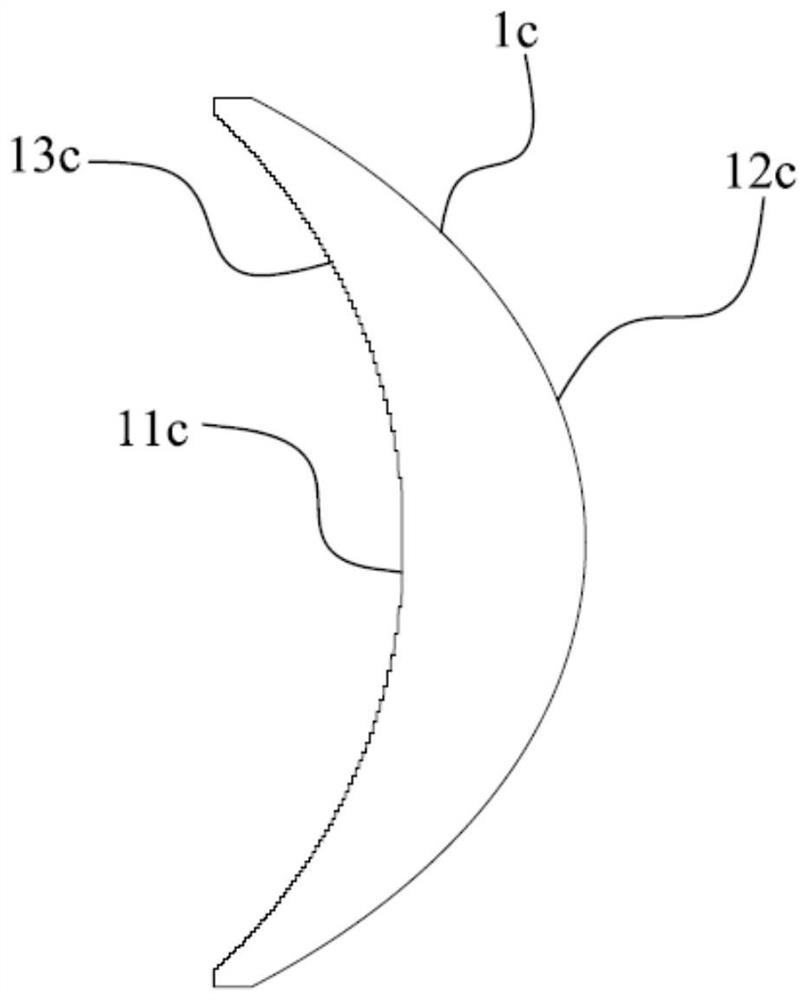

[0061] Such as image 3 As shown, the lens 1c provided by Embodiment 3 of the present invention includes a first surface 11c and a second surface 12c, the first surface 11c of the lens 1c is a binary surface, and the second surface 12c is a smooth surface.

[0062] The difference from Embodiment 1 is that on the binary surface, the width of the multiple serrations 13c along the radial direction of the lens gradually decreases from the center of the lens 1c to the edge of the lens, and the multiple The heights of the serrations 13c along the axial direction of the lens 1c are consistent to form a binary surface of the lens 1c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com