Patching equipment

A technology of equipment and socket parts, which is applied in the direction of connection/disconnection of connection devices, non-rotational vibration suppression, etc., can solve the problems of many artificial influence factors, easily damaged battery module plugs, and low efficiency, so as to buffer impact force, Improve convenience and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0049] The present invention will be described in detail below with reference to the accompanying drawings and examples.

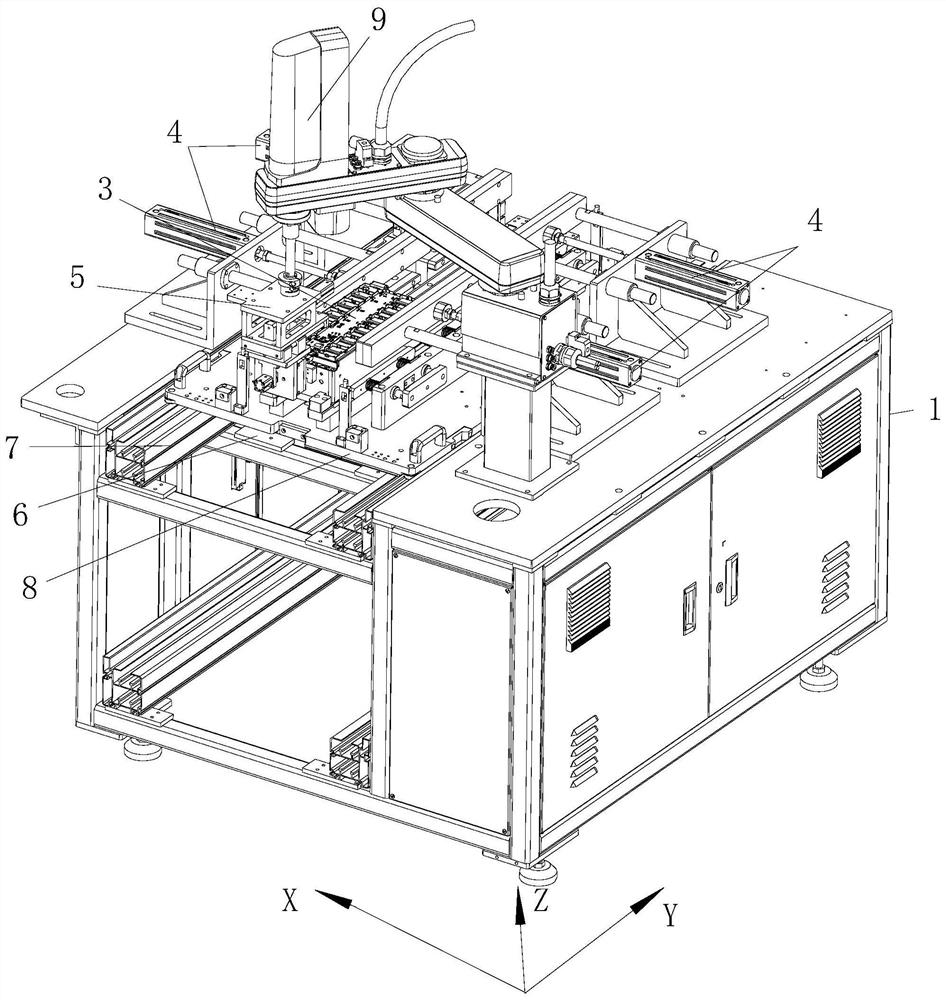

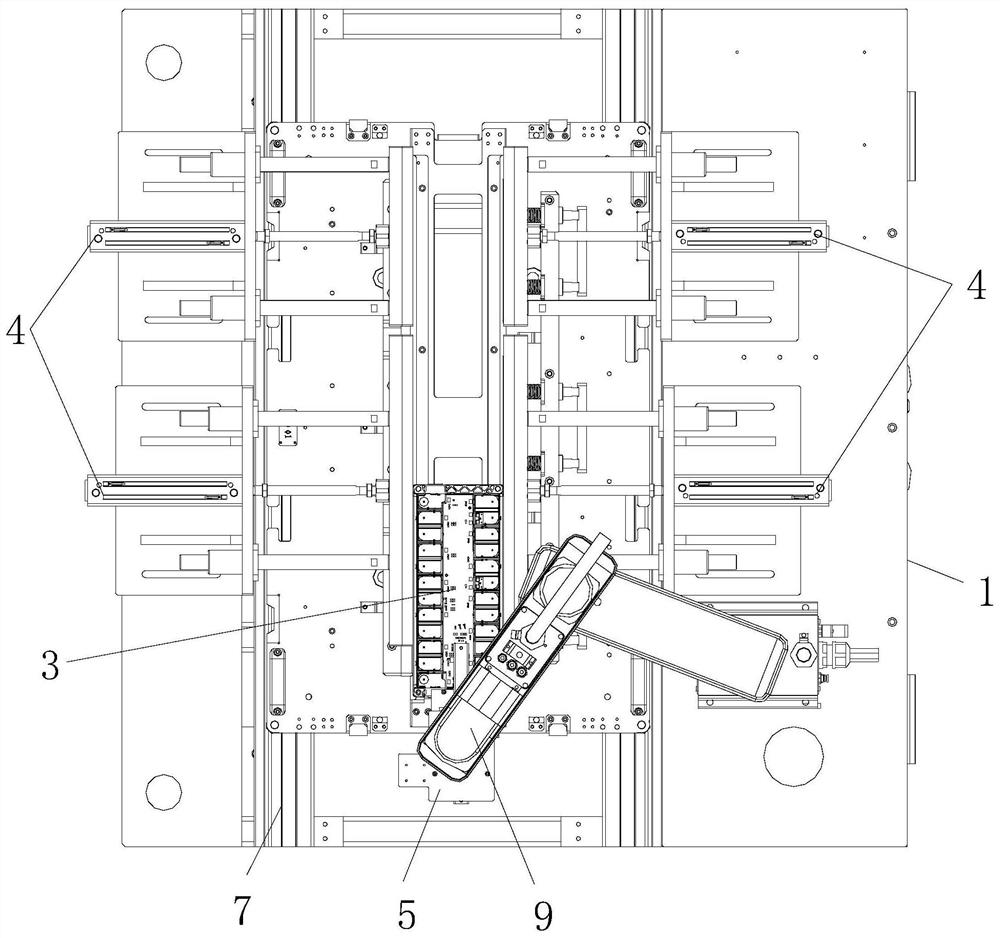

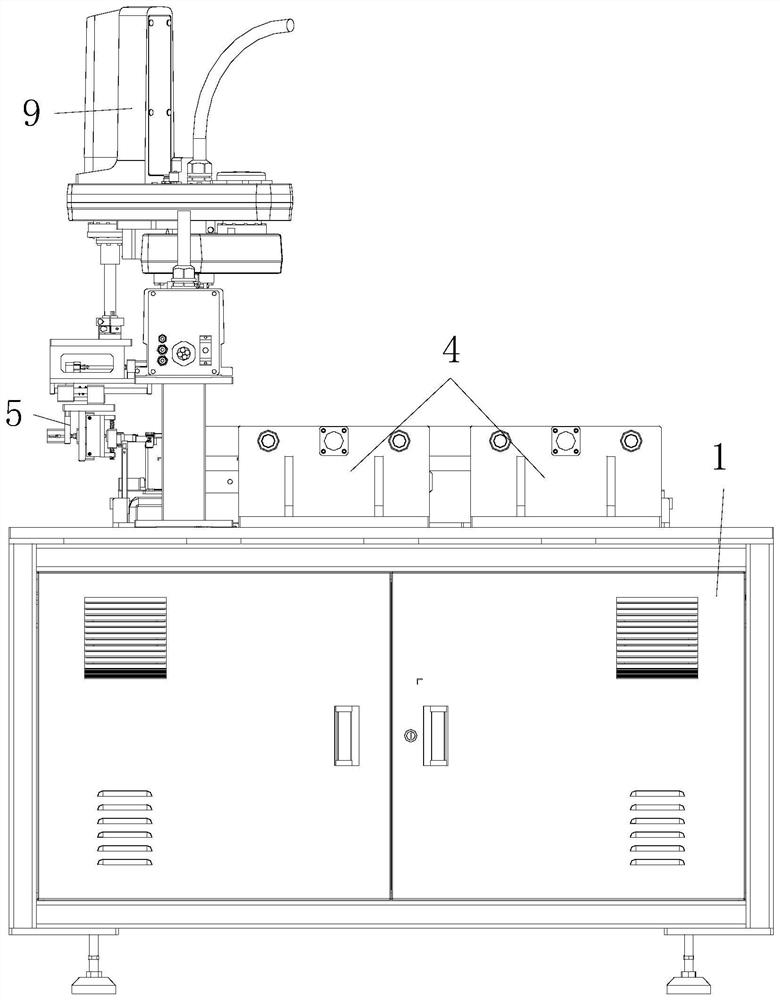

[0050] This embodiment relates to a plug-in device, which mainly includes a frame, and a first holding mechanism and a plug-in device arranged on the frame. The plug-in device includes a plug-in drive mechanism and a carrying unit, and the carrying unit has a floating mechanism, The limiting part and the driving mechanism of the limiting part can realize the smooth insertion of the socket part and the socket matching part, and can effectively prevent the damage of the socket part and the socket matching part.

[0051] Based on the above description of the overall structure, an exemplary structure of the plug-in device in this embodiment is as follows: Figure 1 to Figure 4 As shown, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com