Assembling tool and method for accurately controlling orientation consistency of seed crystals

A precise control and consistent technology, applied in the direction of manufacturing tools, chemical instruments and methods, crystal growth, etc., can solve the problem that the secondary orientation does not have clear requirements, so as to reduce artificial errors, improve efficiency, and high repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

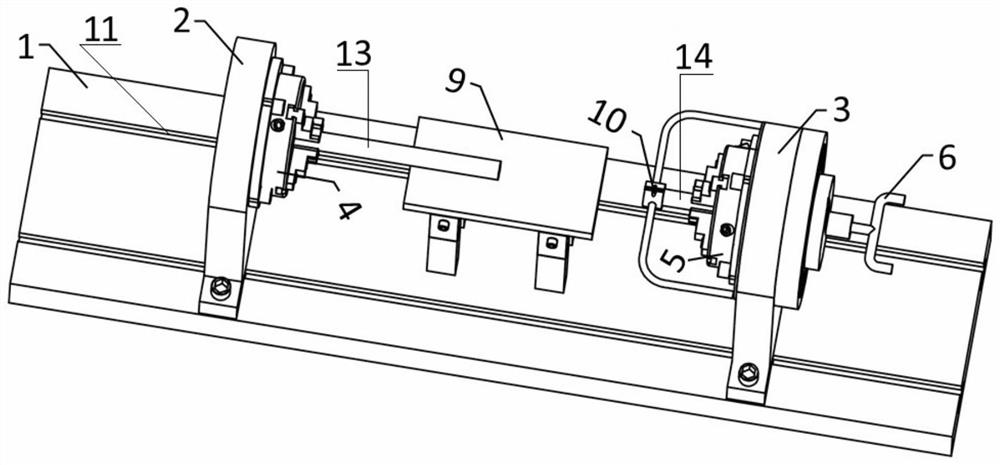

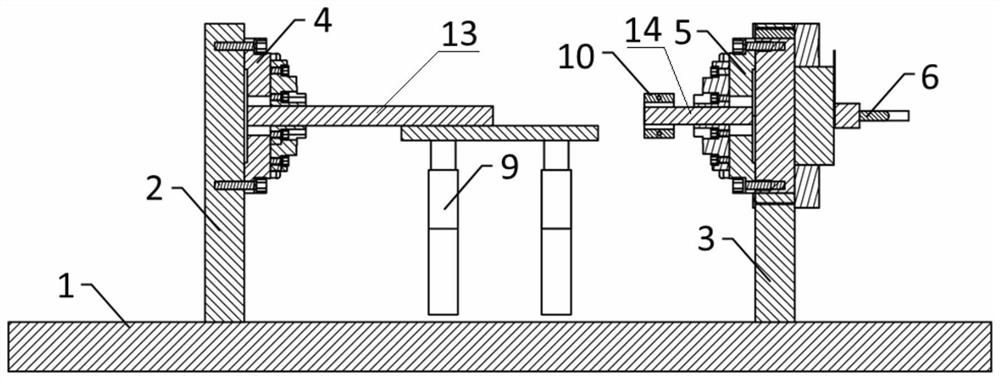

[0055] like Figure 1-Figure 3 As shown, the present embodiment is to assemble the wax mold through the assembly tool in the present invention, and prepare the nickel-based single crystal superalloy test plate with the axial orientation as [001] and the secondary orientation as [001]. The specific process is:

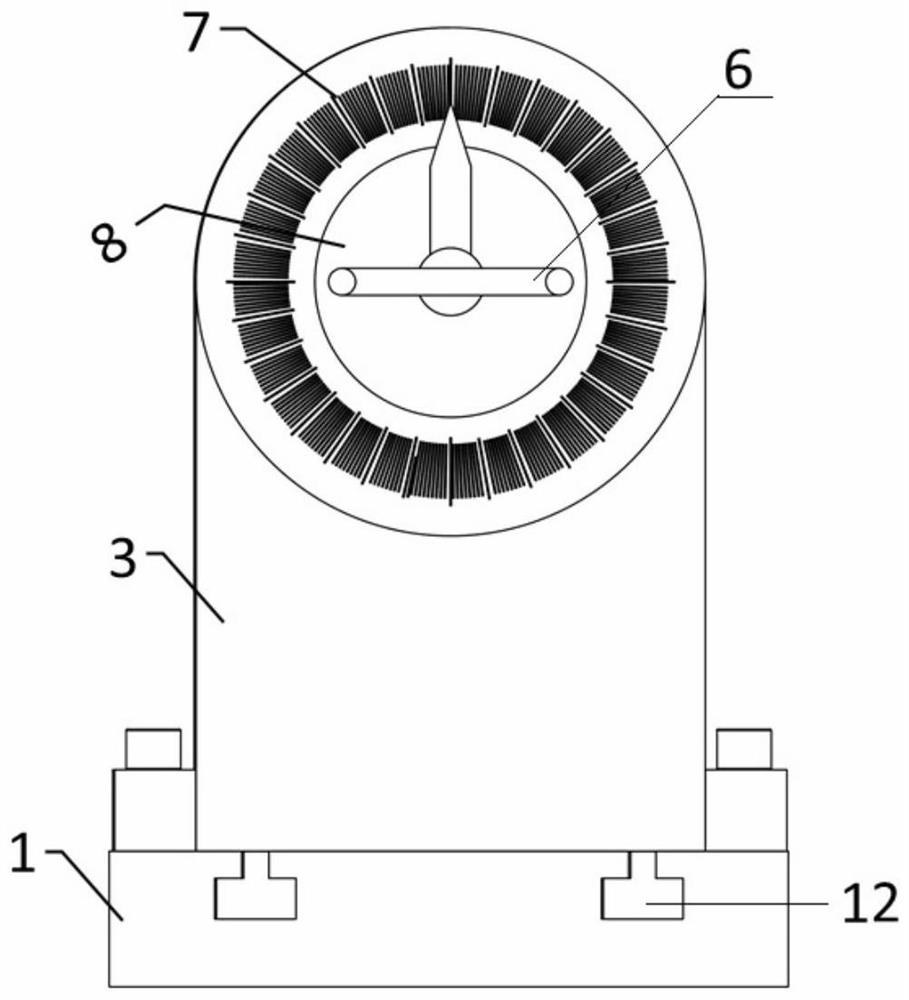

[0056] Step 1, prepare the seed crystal 14 with the axial direction [001] and the secondary orientation [001], and cut out a marking plane perpendicular to the secondary orientation.

[0057] Step 2, preparing the wax mold 13 of the single crystal plate, pouring the melted wax material into the mold, press molding, and taking out the wax mold of the single crystal plate after cooling.

[0058] Step 3, fix the wax model 13 on the four-jaw chuck 4 with the plane upward, and tighten the fixing bolts. At the same time, the liftable supporting platform 9 is raised, so that the wax mold 13 is placed parallel to the slide rail base 1 without deformation.

[0059] Step 4, con...

Embodiment 2

[0067] like Figure 1-Figure 3 As shown, the present embodiment is to assemble the wax mold through the assembly tool in the present invention, and prepare the nickel-based single crystal superalloy test plate with the axial orientation as [001] and the secondary orientation as [011]. The specific process is:

[0068] Step 1, prepare the seed crystal 14 with the axial direction [001] and the secondary orientation [001], and cut out a marking plane perpendicular to the secondary orientation.

[0069] Step 2, preparing the wax mold 13 of the single crystal plate, pouring the melted wax material into the mold, press molding, and taking out the wax mold of the single crystal plate after cooling.

[0070] Step 3, fix the wax model 13 on the four-jaw chuck 4 with the plane upward, and tighten the fixing bolts. Simultaneously, the liftable supporting platform 9 is raised, so that the wax mold 13 is placed parallel to the slide rail base 1 without deformation.

[0071] Step 4, confi...

Embodiment 3

[0079] like Figure 1-Figure 3 As shown, in this embodiment, a wax mold is assembled by an assembly tool in the present invention, and a nickel-based single crystal superalloy blade with an axial orientation of [001] and a secondary orientation of [001] is prepared. The specific process is:

[0080] Step 1, prepare the seed crystal 14 with the axial direction [001] and the secondary orientation [001], and cut out a marking plane perpendicular to the secondary orientation.

[0081] Step 2, preparing the single crystal blade wax mold 13, pouring the melted wax material into the mould, press molding, and taking out the single crystal blade wax mold after cooling.

[0082] Step 3, fix the wax model 13 on the four-jaw chuck 4 with the plane upward, and tighten the fixing bolts. Simultaneously, the liftable supporting platform 9 is raised, so that the blade wax mold 13 is placed parallel to the slide rail base 1 without deformation.

[0083] Step 4, confirm that the pointer 8 is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com