Bearing automatic grease injection system

An automatic and bearing technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of unsuitable for large quantities of bearings, inconvenient use, uneven grease injection, etc., achieve better grease injection effect, reduce Waste, high efficiency of bearing grease injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

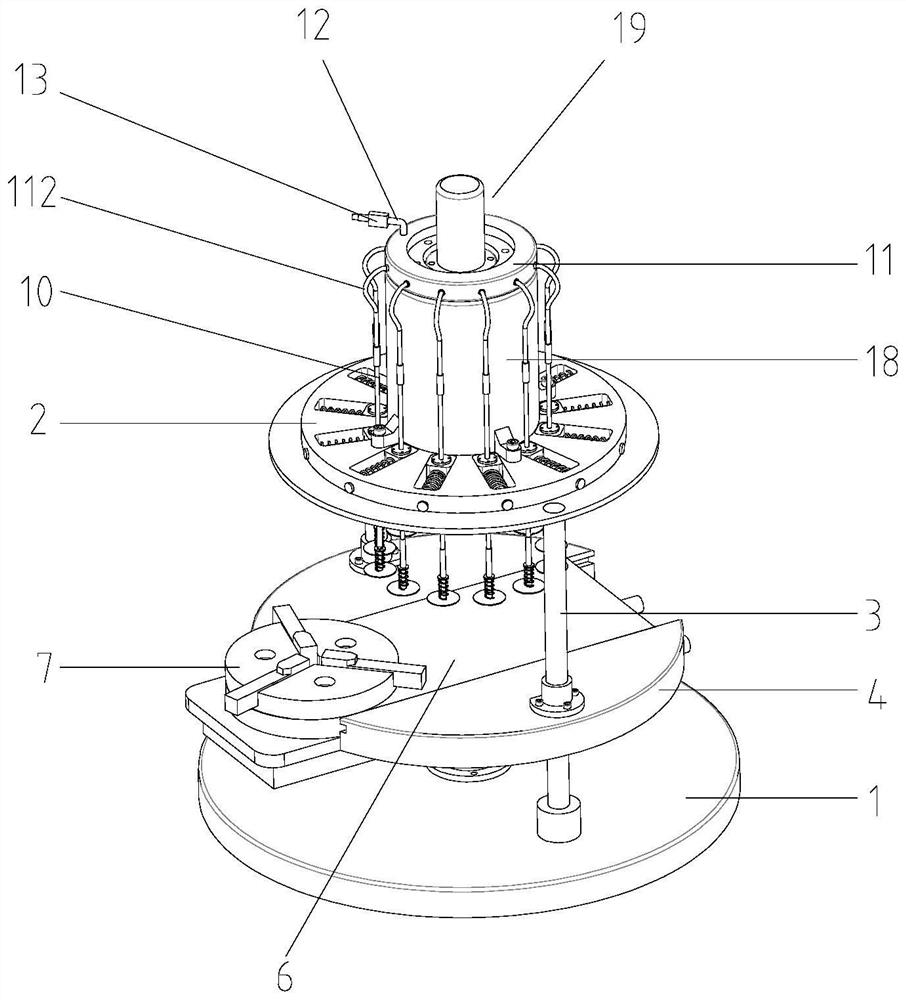

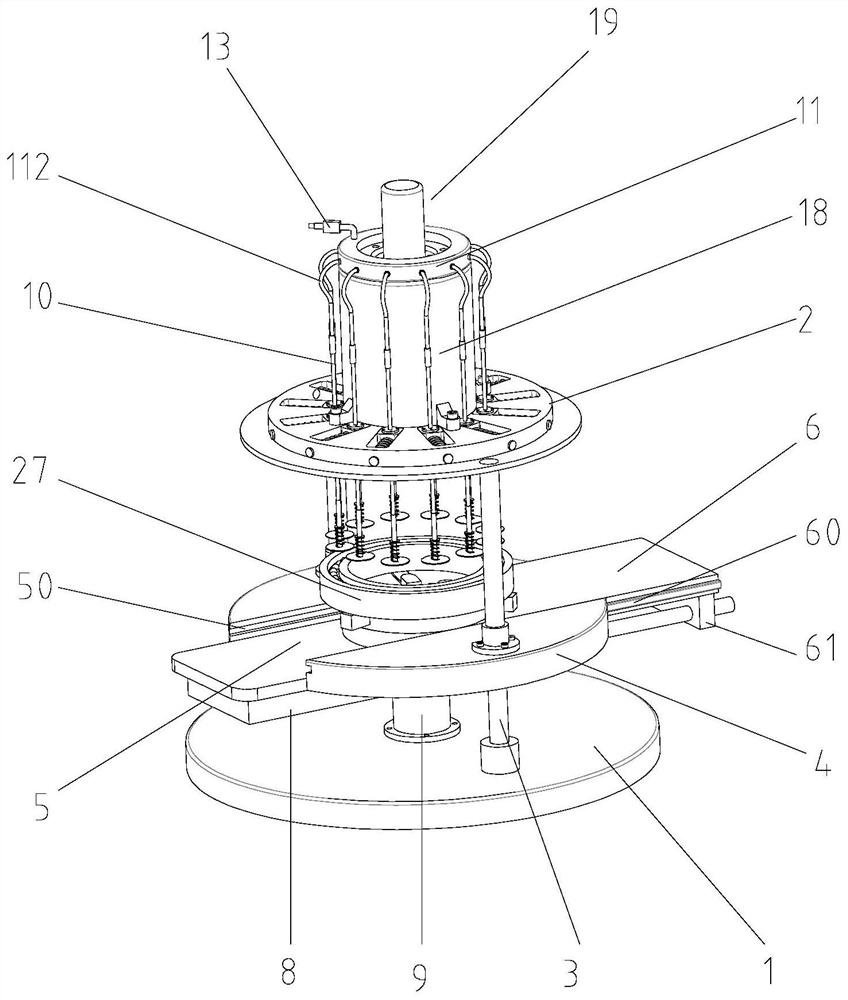

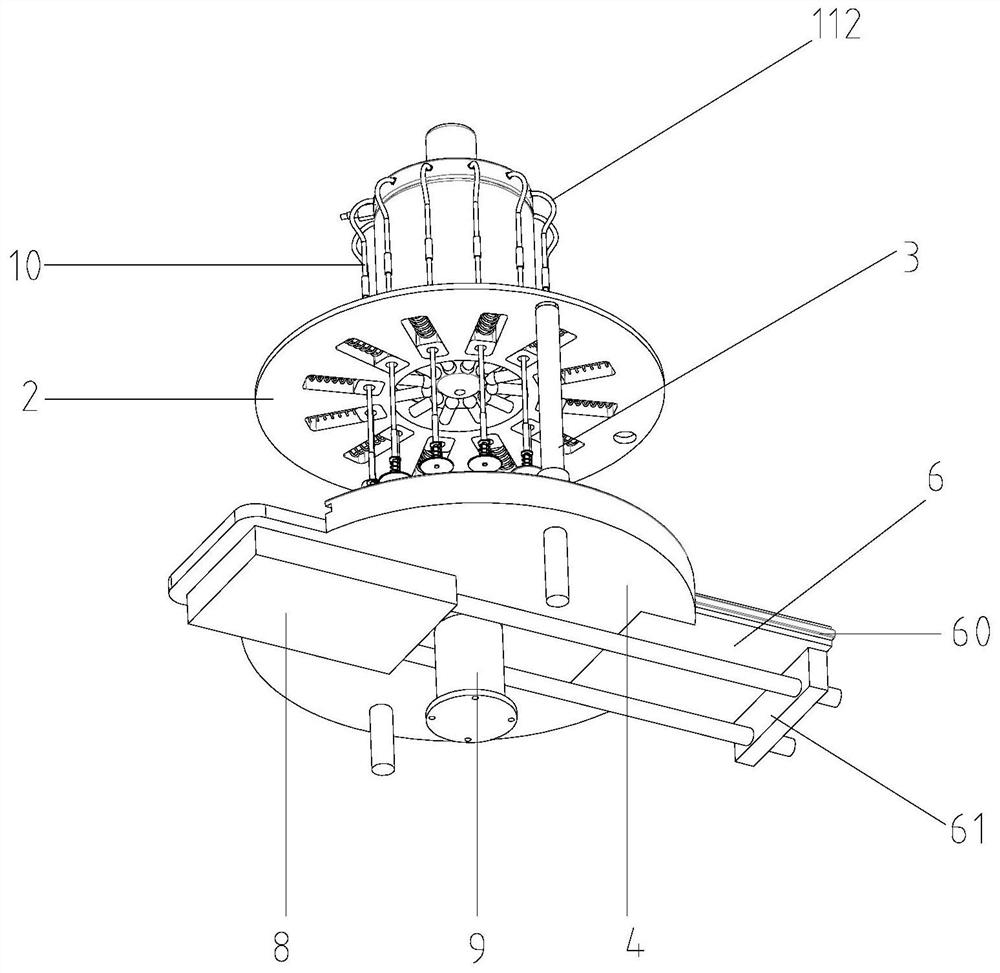

[0027] Such as figure 1 , figure 2 , image 3 The shown automatic grease injection system for bearings includes a base 1, a base 2 is provided above the base 1, and the base and the base are connected by two guide posts 3, and a lifting seat 4 is provided between the guide posts to lift The top surface of seat 4 is provided with chute 5, is provided with slide plate 6 in the groove, and the both sides of chute 5 is provided with limit groove 50, and the both sides of slide plate 6 is provided with the limit protruding bar that slides with limit groove. 60, the bottom of the rear end of the slide plate 6 is provided with a connecting block 61, and the top surface of the front end of the slide plate 6 is fixed with a chuck 7. The chuck in this embodiment adopts a pneumatic chuck, and the bottom surface of the front end of the base is fixed with a le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com