Die for casting casting

A technology of castings and molds, applied in the field of castings, can solve the problems of long solidification into castings, low production efficiency, long cooling time, etc., and achieve the effects of increasing molding speed, improving work efficiency, and preventing outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

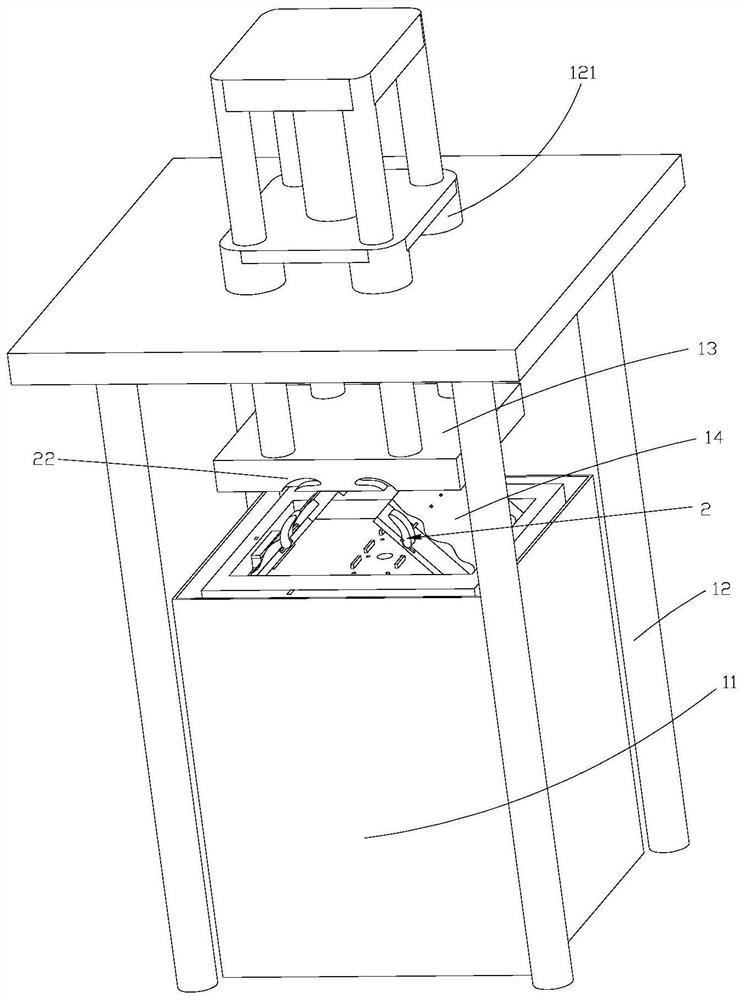

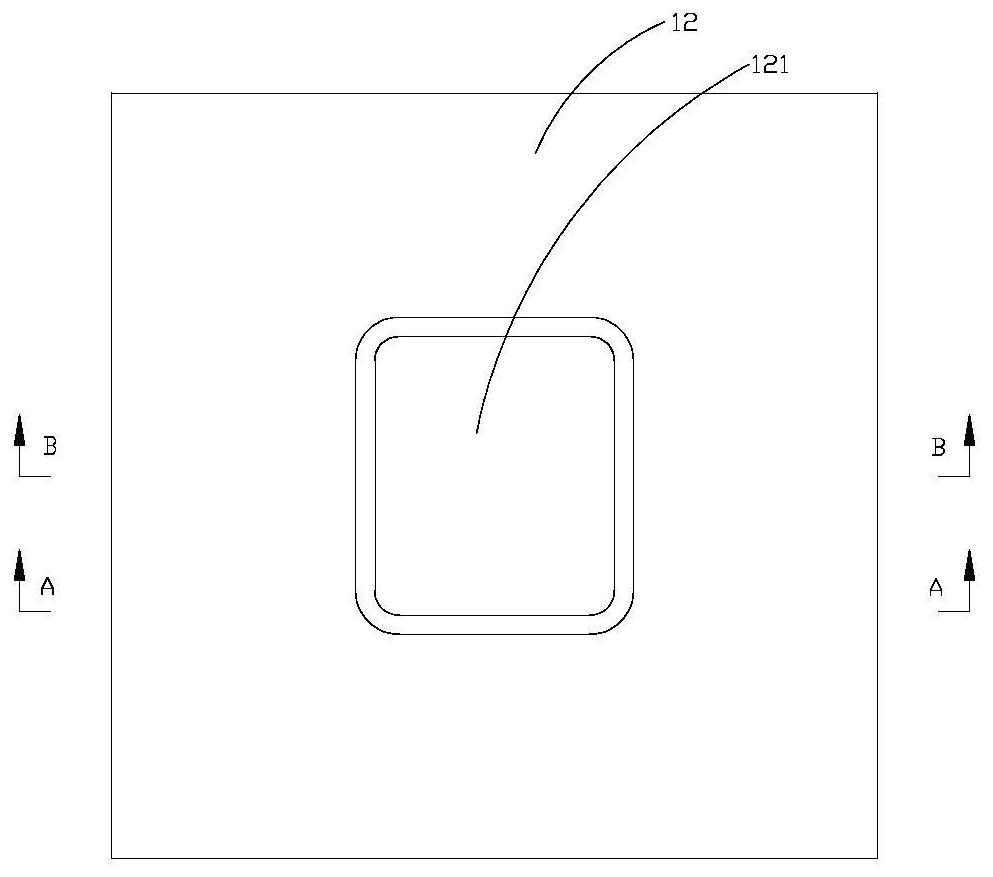

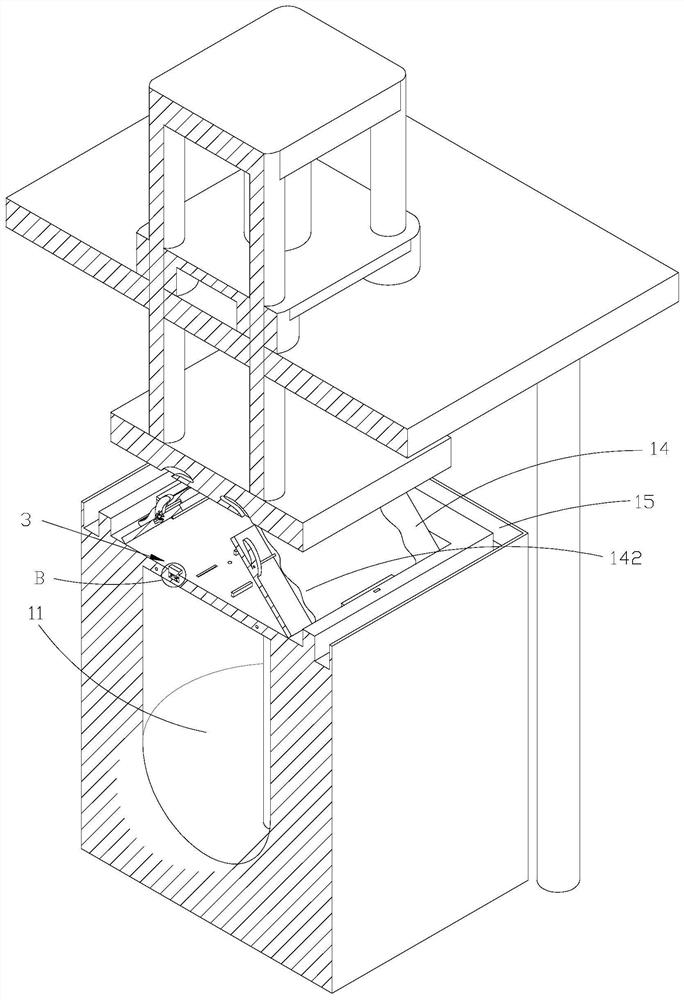

[0025] like Figure 1-9 Shown, a kind of mold for casting casting comprises equipment frame 1, crucible chamber 11, support frame 12, hydraulic cylinder 121, upper template 13, die groove 131, lower template 14, first torsion spring 141, convex module 142, Water storage tank 15, transportation pipe 16, gas filling port 17, cooling chamber 18, first port 19, driving part 2, cooling part 5, connecting part 7; crucible chamber 11 is arranged on equipment frame 1, and hydraulic cylinder 121 is arranged On the support frame 12, the upper template 13 is arranged on the hydraulic cylinder 121, the die groove 131 is arranged on the upper template 13, the lower template 14 is rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com