Micro-fluidic multi-gear flow regulator

A flow regulator and flow regulating valve technology, which is applied in valve devices, sliding valves, mechanical equipment, etc., can solve the problems of small size, low stability, and poor quantification of microfluidic flow regulators, so as to improve convenience and efficiency. Practicality, improved stability, improved reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

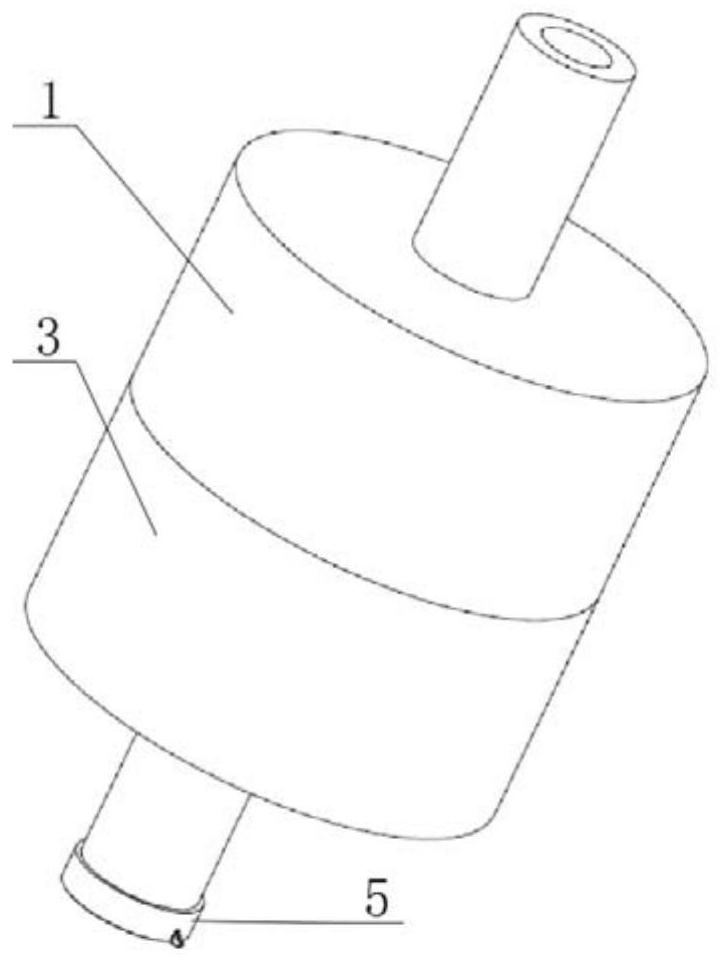

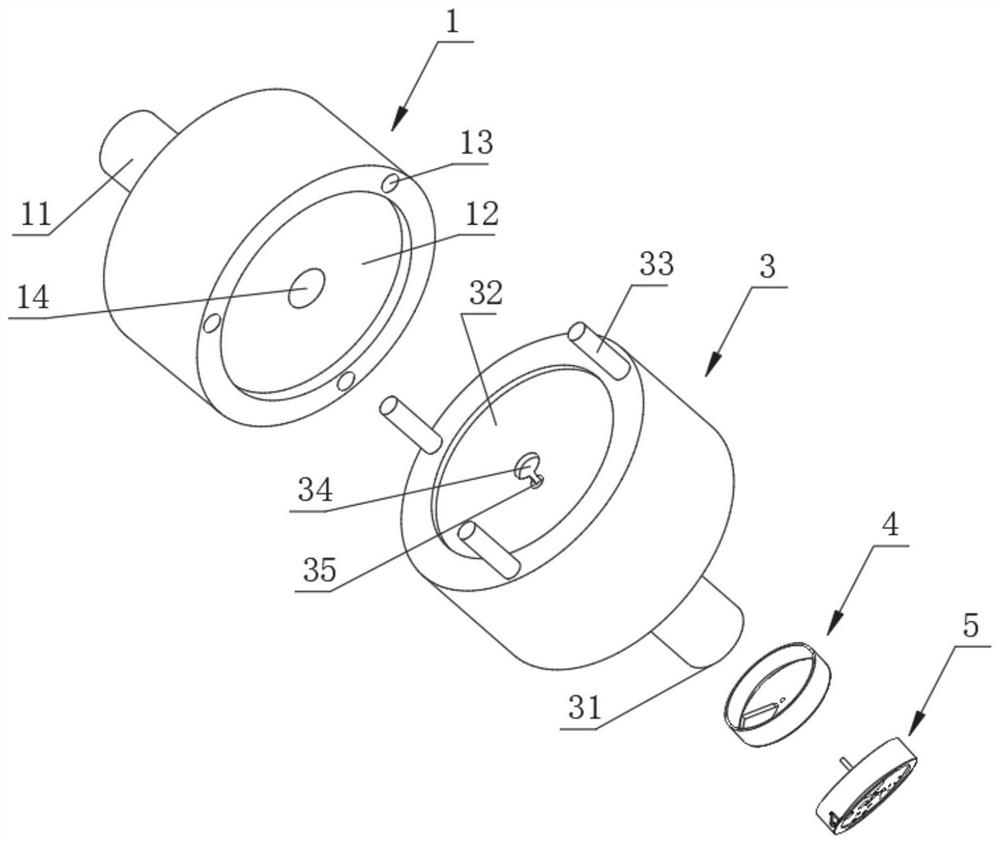

[0025] Such as figure 1 and figure 2 As shown, the microfluidic multi-position flow regulator of this embodiment includes an inflow part 1 and an outflow part 3 communicating with the inflow part 1, and a flow regulating valve is arranged at the outflow end of the outflow part 3 to adjust the flow rate. The valve includes a fixed baffle part 4, and the fixed baffle part 4 is rotationally connected with the adjusting baffle part 5;

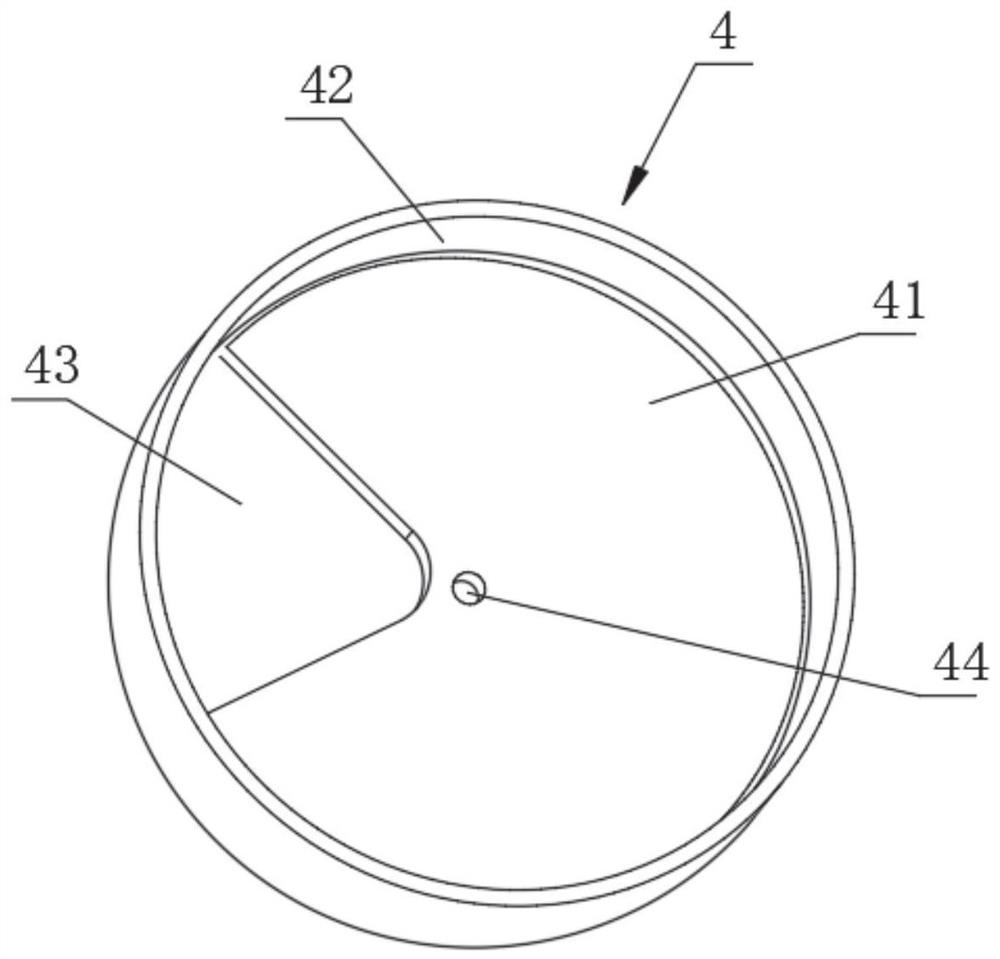

[0026] Such as image 3 and Figure 4 As shown, the fixed baffle part 4 has an outlet surface 41, which is provided with a fixing hole 43 communicating with the outlet end, and the adjustment baffle part 5 has a corresponding fitting with the outlet surface 41 and can be relatively rotated. The inflow surface 51 is provided with a plurality of hollow parts with different flow areas. When the inflow surface 51 rotates relative to the outflow surface 41, each hollow part makes the opening of the fixing hole 43 be covered with different areas. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com