Bottom plate bolt loss detection method based on image processing

An image processing and missing detection technology, which is applied in image data processing, image enhancement, image analysis, etc., can solve the problems of low detection accuracy and missing bottom plate bolts, and achieve the effect of improving image distortion and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

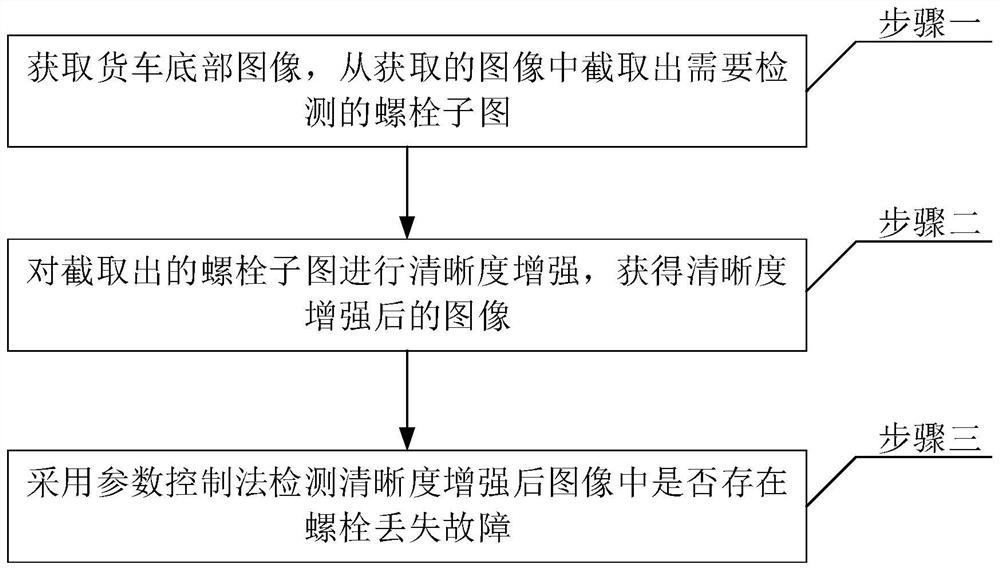

[0029] Specific implementation mode 1. Combination figure 1 This embodiment will be described. A kind of base plate bolt missing detection method based on image processing of the present embodiment, it specifically is:

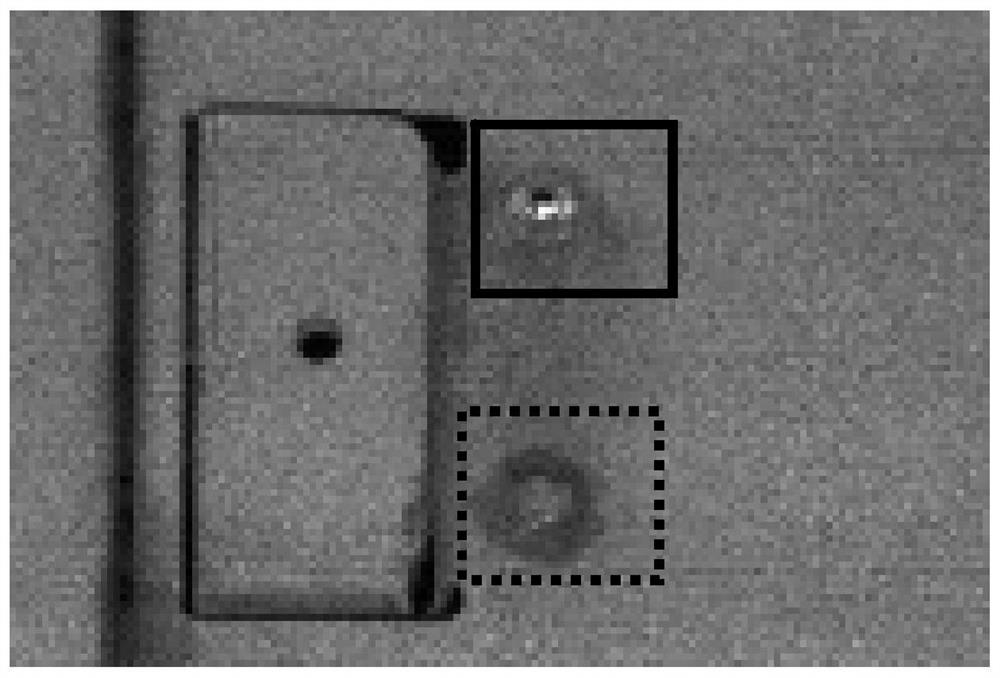

[0030] Step 1. Obtain the bottom image of the truck, and extract the bolt sub-image to be detected from the obtained image;

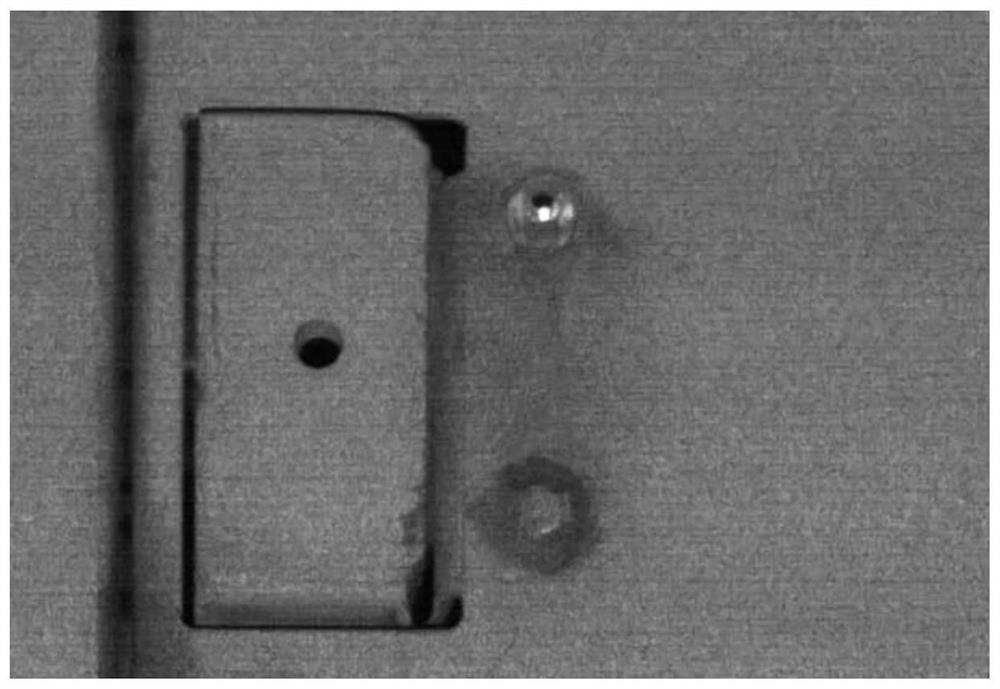

[0031] Step 2, performing definition enhancement on the intercepted bolt sub-picture to obtain a definition-enhanced image;

[0032] Step 3. Use the parameter control method to detect whether there is a bolt missing fault in the image after the definition is enhanced; the specific process is:

[0033] Step 31. According to the size of the bolt in the sharpness-enhanced image under normal circumstances, set the pixel block size to a×a, divide the a×a pixel area in the upper left corner of the sharpness-enhanced image into a pixel block, and the pixel block Sliding window movement is performed on the sharpness-enhanced image with a ste...

specific Embodiment approach 2

[0040] Specific implementation mode two, the difference between this implementation mode and specific implementation mode one is: the specific process of step two is:

[0041] Step 21. Perform particle removal on the intercepted bolt sub-image to obtain an image after particle removal;

[0042] Step 22: Traverse the intercepted bolt sub-image and the pixels of the image after particle removal to obtain the gray value of the pixel at the same position of the two images, and then calculate the average of the two gray values at the same position, Multiply the average value by the coefficient weight r to get a new gray value;

[0043] Use the new gray value to replace the gray value of the pixel in the image after particle removal (that is, use the new gray value to replace the gray value of the same position in the image after particle removal), and after the replacement is completed, the definition is enhanced Image.

specific Embodiment approach 3

[0044] Specific implementation mode three, the difference between this implementation mode and specific implementation mode two is: the specific process of step 21 is:

[0045] Let f(x,y) be the intercepted bolt subgraph, x and y are the row and column coordinates of the intercepted bolt subgraph respectively, G(x,y) is a two-dimensional Gaussian function, E avr (x,y) is the image averaging function:

[0046]

[0047]

[0048] Where: e is the base of natural logarithm, σ is the standard deviation of the two-dimensional Gaussian function, μ f(x,y) is the average gray value of the pixel in f(x,y), W is the width of f(x,y), and H is the height of f(x,y);

[0049] f dis (x,y)=G(x,y)*E avr (x,y)

[0050] Among them, f dis (x,y) is the image after particle removal, and * represents multiplication.

[0051] E. avr The (x, y) average function, as can be seen from the formula, calculates the difference between the grayscale difference between adjacent pixels and the averag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com