Air freshener as well as preparation process and preparation system thereof

An air freshener and preparation system technology, which can be used in deodorization, disinfection and other directions, and can solve the problem of inability to form viscous liquid air fresheners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

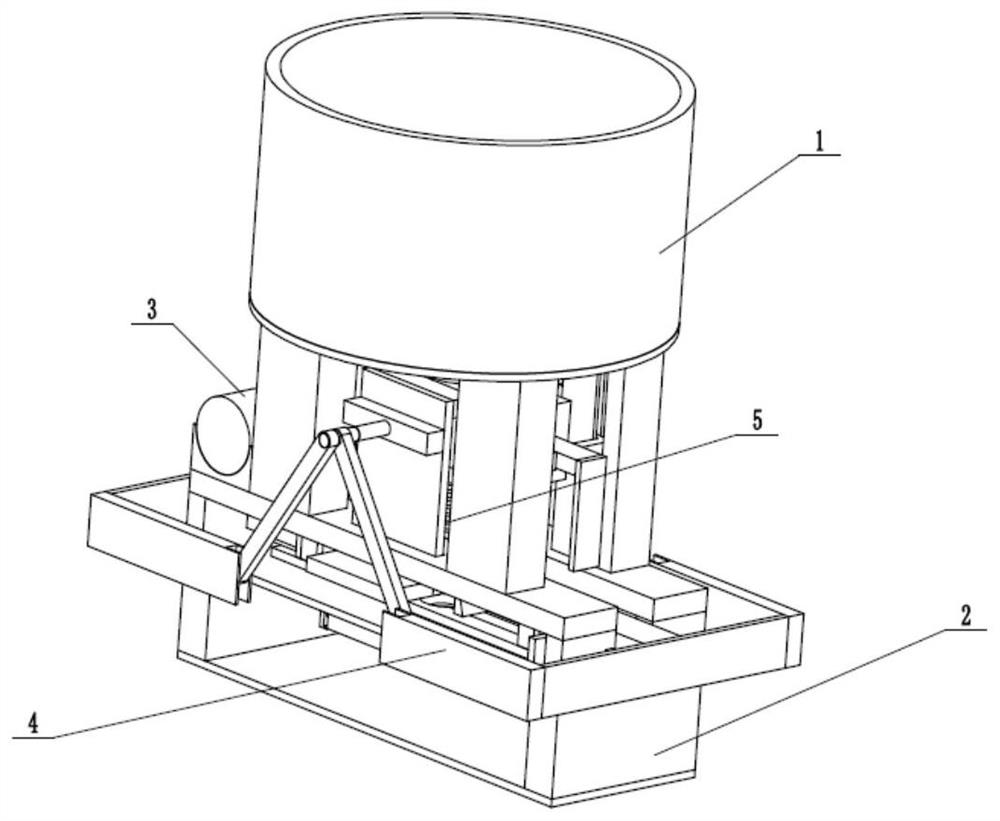

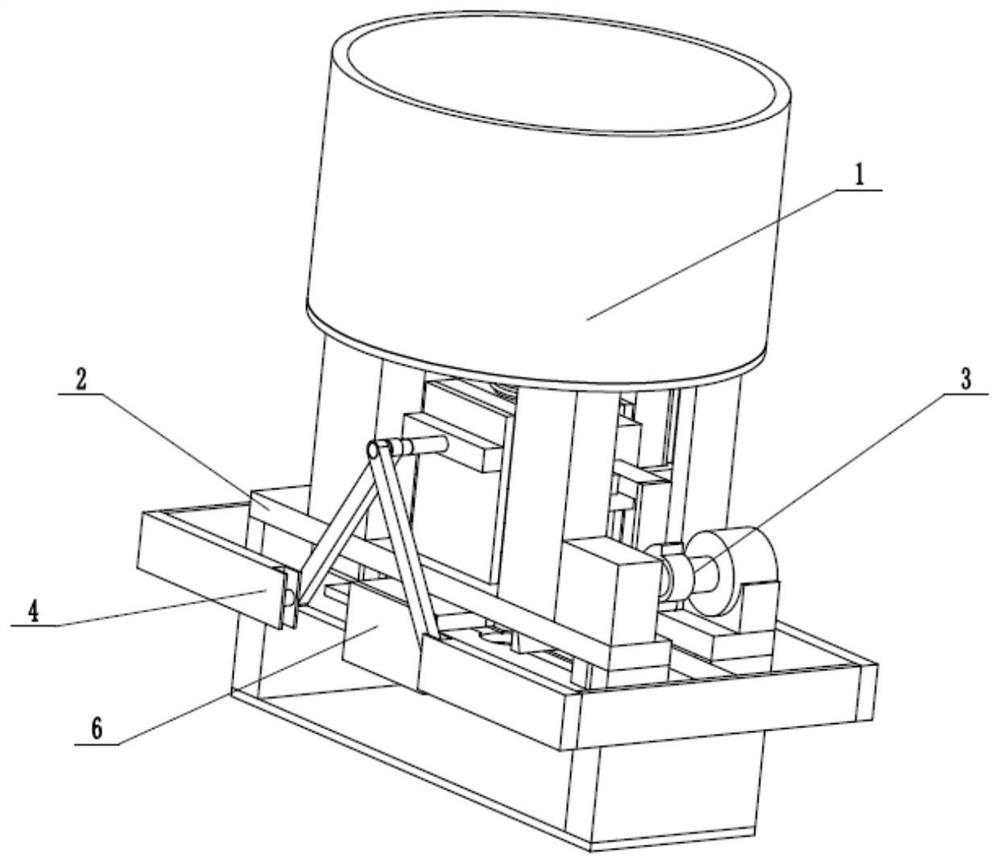

[0035] like Figure 1 to Figure 12 As shown, an air freshener preparation system includes a mixing and adding cylinder base 1, a processing base 2, an adding combination driver 3, a condensing molder 4, an automatic adding switch 5 and a drop combiner 6, and the mixing and adding cylinder base 1 Fixedly connected to the upper end of the processing base 2, the adding combination driver 3 is longitudinally reciprocatingly slidably connected in the processing base 2 and connected to the mixing and adding cylinder base 1, the condensation forming device 4 is fixedly connected to the front and rear ends of the adding combination driving device 3, and the condensation forming device 4 Slidingly connected in the processing base 2, the automatic adding switch 5 is fixedly connected to the lower end of the adding combination driver 3 and communicates with the adding combination driver 3 and the mixing and adding cylinder seat 1, and the drop combiner 6 is fixedly connected to the adding...

specific Embodiment approach 2

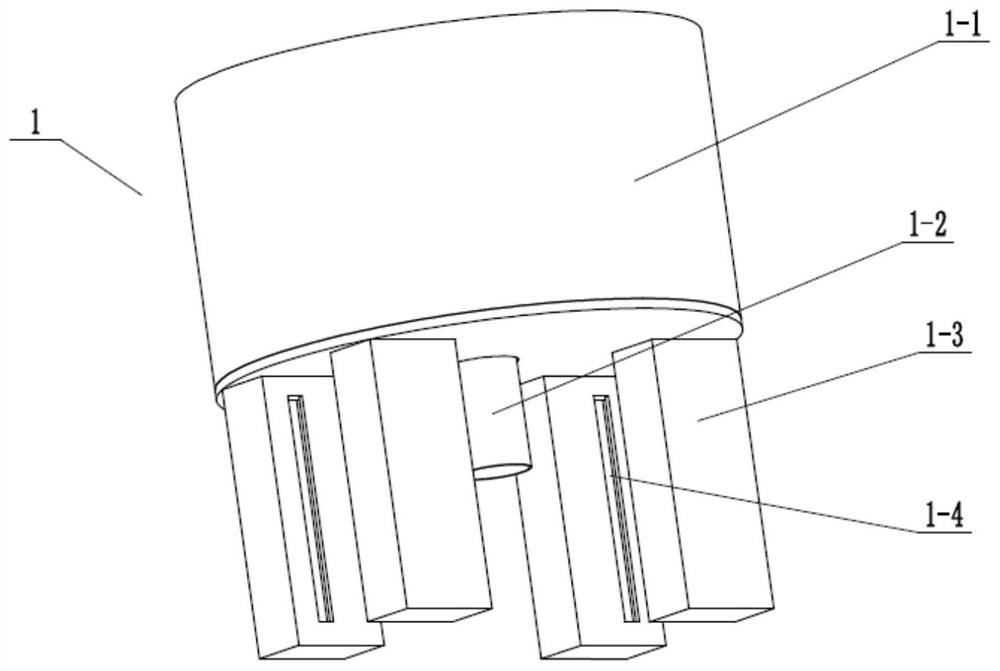

[0037] like Figure 1 to Figure 12 As shown, this embodiment will further describe Embodiment 1. The mixing and adding cartridge base 1 includes a mixing cylinder 1-1, a communicating adding pipe 1-2, four sliding support plates 1-3 and four T-shaped longitudinal The chute 1-4, the lower end of the mixing cylinder 1-1 is fixedly connected and communicated with the adding pipe 1-2, the four sliding support plates 1-3 are evenly fixed and connected to the lower end of the mixing cylinder 1-1, and the four T-shaped The longitudinal chute 1-4 is respectively arranged on the four sliding support plates 1-3. The viscous liquid air freshener formed by the mixing splint is stored in the mixing cylinder 1-1, and the viscous liquid air freshener is discharged through the connecting pipe 1-2.

specific Embodiment approach 3

[0039] like Figure 1 to Figure 12 As shown, this embodiment further explains the second embodiment. The processing base 2 includes a front fixing recess 2-1, a rear fixing recess 2-2, two longitudinal rectangular chute 2-3, and a motor fixing seat. 2-4, rotating shaft seat 2-5, lateral limit chute 2-6, center base plate 2-7, lower base 2-8, condensation extrusion slide seat 2-9, condensation extrusion chute 2-10, Two sliding seats 2-11 and forming drop round hole 2-12, front fixed recess 2-1 and rear fixed recess 2-2 are all fixedly connected on the center base plate 2-7, two longitudinal rectangular chute 2- 3 respectively vertically penetrate the front fixed recess 2-1 and the rear fixed recess 2-2, the rotating shaft seat 2-5 and the motor fixed seat 2-4 are fixedly connected to the front fixed recess 2-1 and the rear fixed seat 2-1 respectively On the concave seat 2-2, the lateral limit chute 2-6 runs through and is arranged between the front fixed concave seat 2-1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com