Testing machine used for detecting dynamic friction torque of turret seat ring

A technology of friction torque and testing machine, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc. It can solve the problems of inaccurate measurement, low intelligence, and high physical exertion, and achieve accurate measurement results , High degree of intelligence and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

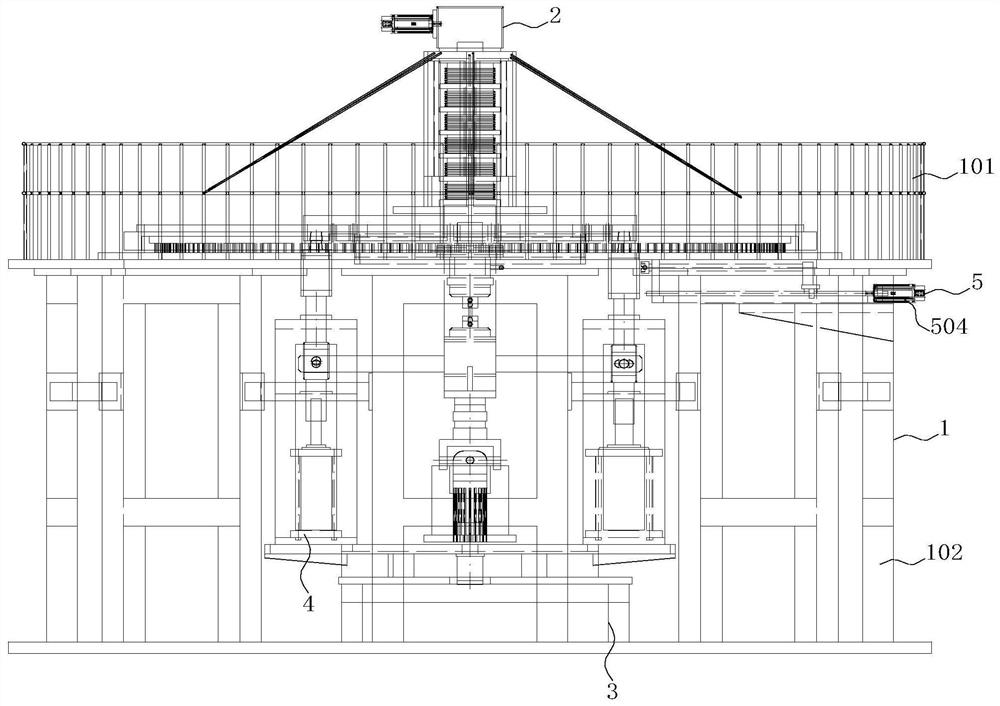

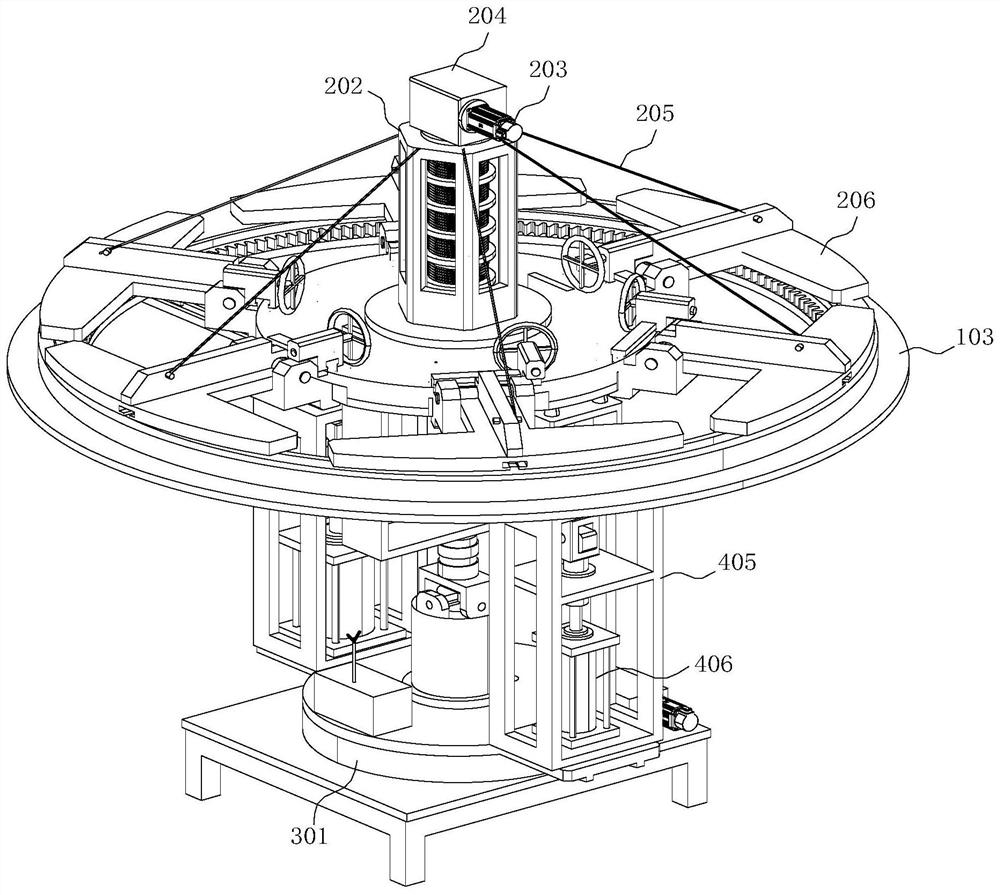

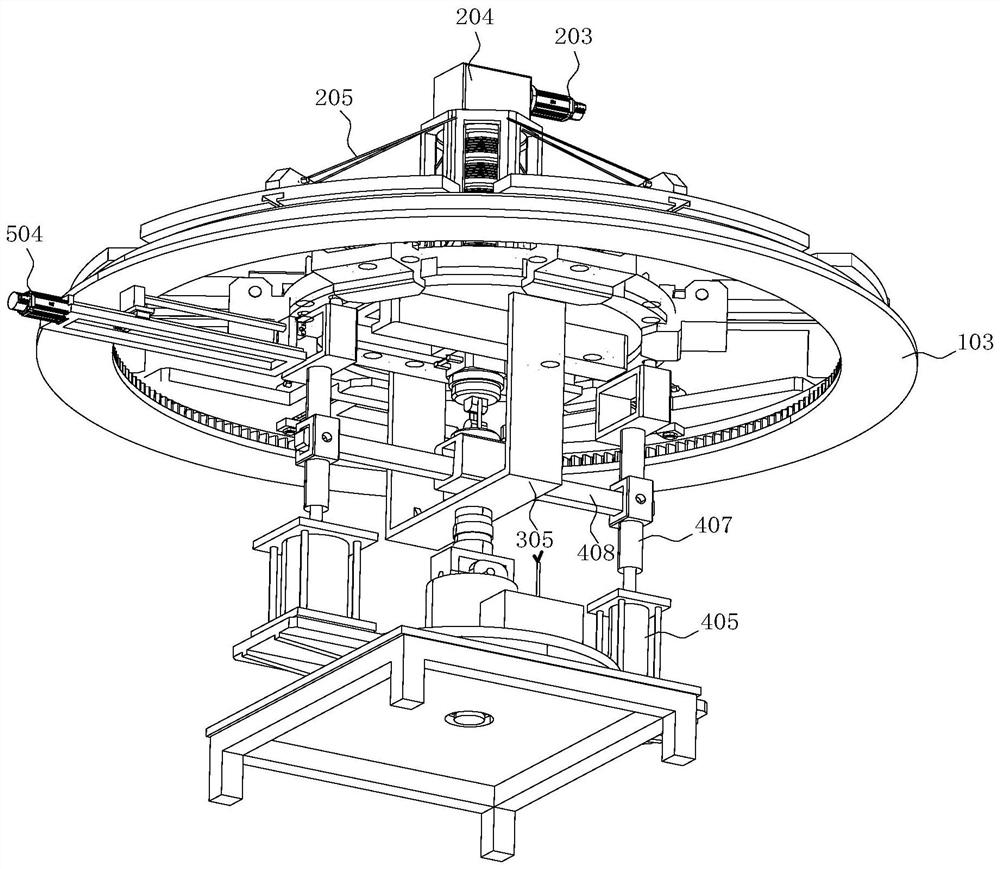

[0059] See attached figure 1 - attached Figure 9 , the testing machine for detecting the dynamic frictional moment of the turret race of the present invention comprises:

[0060] Basic support frame 1;

[0061] The seat ring positioning and clamping device 2 located above the basic support frame 1, the seat ring to be detected is positioned and pressed on the basic support frame 1 through the seat ring positioning and clamping device 2;

[0062] The torque drive device 3 provided on the basic support frame 1, the torque drive device 3 at least includes a rotary drive device 301 and a torque sensor 304, through which the rotary drive device 301 drives the seat ring positioning and clamping device 2 The upper ring and the lower ring of the seat ring rotate relatively; the torque sensor 304 is arranged on the rotary shaft of the rotary drive device 301 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com