Glass impact type detection device in intelligent manufacturing

A detection device and intelligent manufacturing technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high manpower consumption, low work efficiency, inaccurate detection results, etc., and achieve the goal of improving work efficiency, convenient detection, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

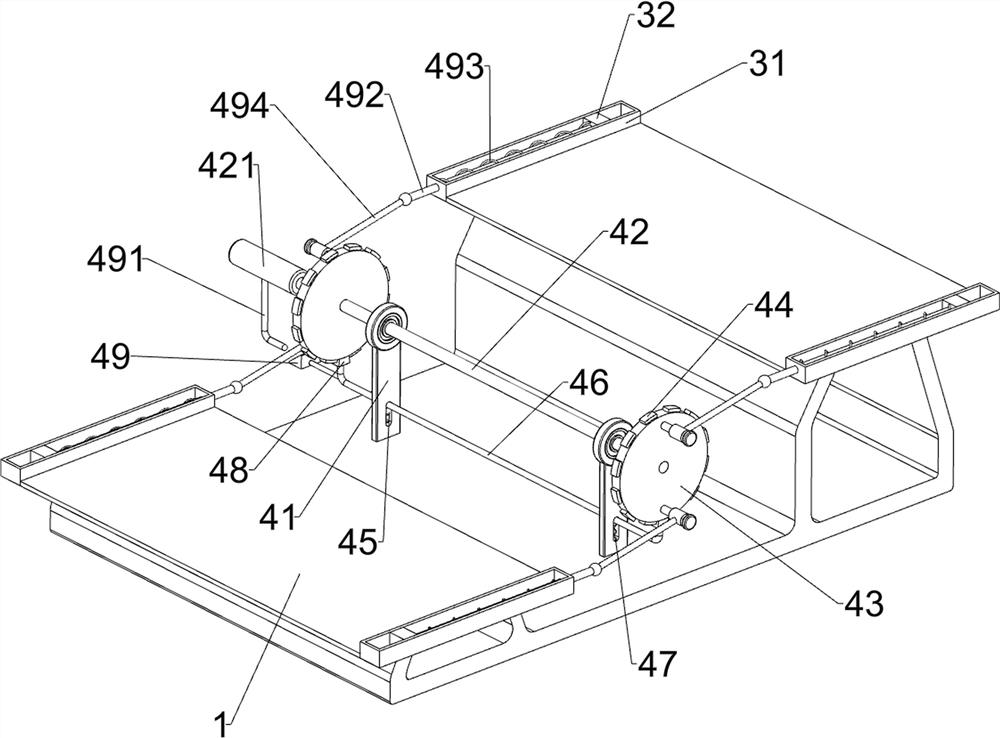

[0026] A glass impact detection device in intelligent manufacturing, such as figure 1 As shown, it includes an installation base 1, an impact assembly 2 and a placement assembly 3. The installation base 1 is provided with an impact assembly 2 that impacts by sliding, and the installation base 1 is provided with a placement assembly 3 that is placed by sliding. .

[0027] When using the device, the worker puts the glass to be tested into the placement component 3, and then detects the glass by hitting the component 2. After completion, the worker removes the tested glass for replacement.

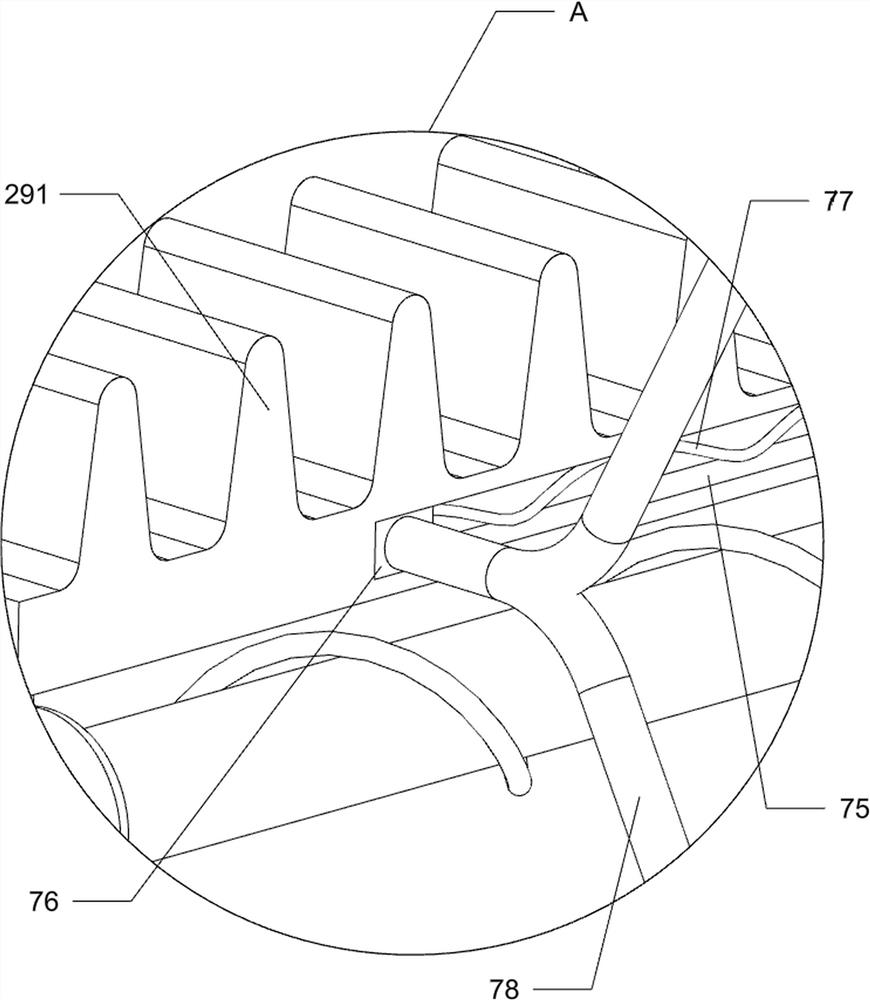

[0028] Such as figure 1 , figure 2 with Figure 8 As shown, the impact assembly 2 includes a mounting plate 21, a geared motor 22, a mounting sleeve 23, a large gear 24, a cylindrical push rod 25, a first wedge block 26, a guide sleeve 27, a slide bar 28, a first spring 29, and a first spring 29. A tooth bar 291 and an impact block 292, the mounting base 1 is provided with a mounting pla...

Embodiment 2

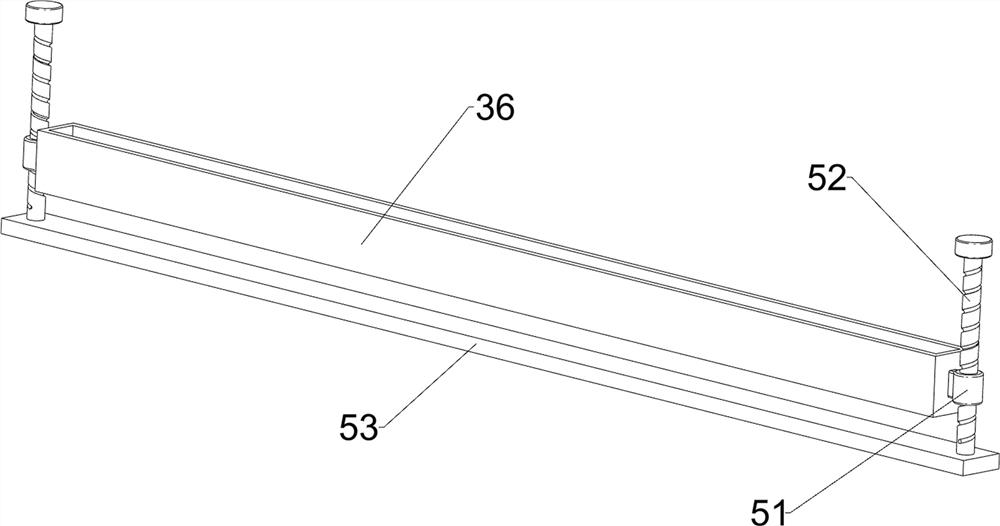

[0033] On the basis of Example 1, such as figure 1 with Figure 4 As shown, a distance adjustment assembly 4 is also included, and the distance adjustment assembly 4 includes a mounting block 41, a rotating shaft 42, a first handle 421, a turntable 43, a protrusion 44, a U-shaped bar 46, a second spring 47, a block 48, a second Two wedge-shaped blocks 49, L-shaped bar 491, pull bar 492, the 3rd spring 493 and connecting rod 494, two parts before and after the mounting base 1 are all provided with mounting block 41, and the rotating type is provided with rotating shaft 42 between front and back two mounting block 41 tops , the rear part of the rotating shaft 42 is slidingly provided with a first handle 421, the front and rear parts of the rotating shaft 42 are provided with a turntable 43, the periphery of the turntable 43 is provided with a circle of protrusions 44, and the lower part of the mounting block 41 has a word hole 45, two words Sliding between the holes 45 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com