Hardware copper-iron wire end sorting device

A sorting device and iron wire technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of low work efficiency, finger pricking by thread ends, troublesome operation, etc., and achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

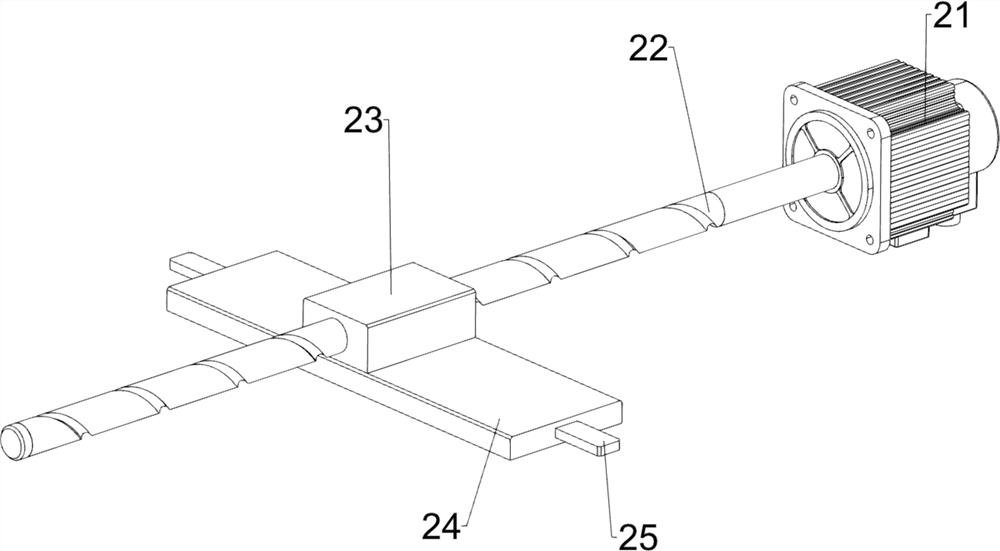

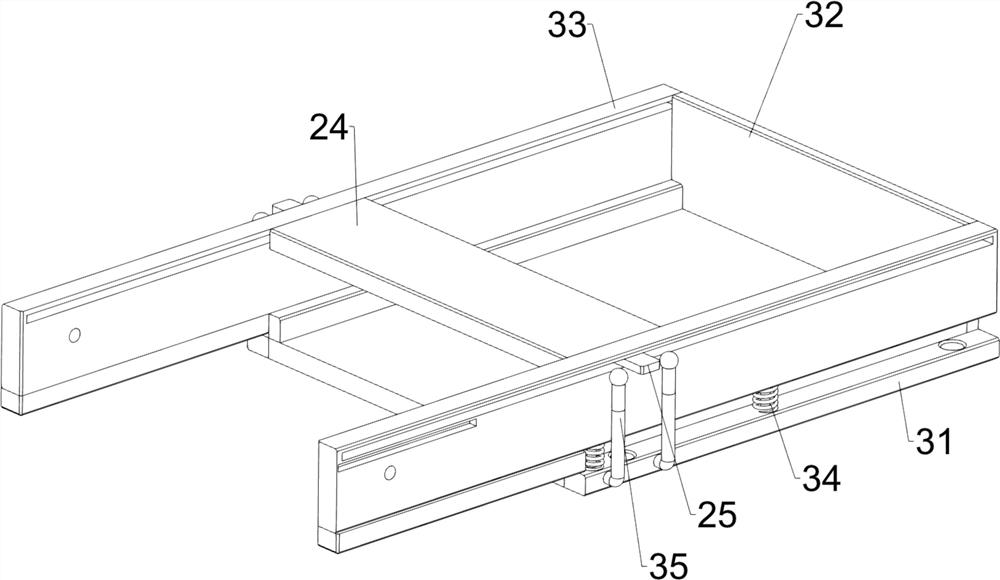

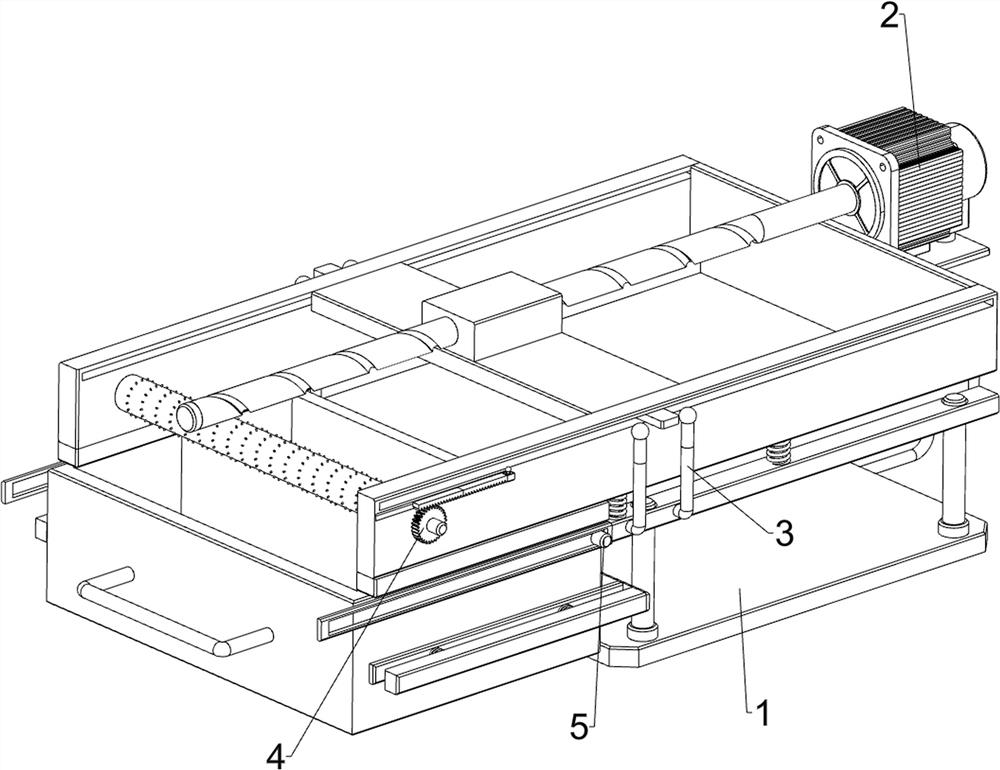

[0024]A sorting device for hardware copper and iron thread ends, such asFigure 1-3As shown, it includes a bracket 1, an iron suction component 2 and a material shaking component 3. The upper side of the bracket 1 is provided with an iron suction component 2, and the upper side of the bracket 1 is provided with a material shaking component 3, and the iron suction component 2 is matched with the material shaking component 3 .

[0025]When you need to sort the copper and iron wire ends, first place the copper and iron wire ends in the shaker assembly 3, and then control the iron suction assembly 2 to start working. The iron suction assembly 2 will take out the iron in the shaker assembly 3, and then The iron on the iron suction assembly 2 can be removed, and the above operations can be repeated continuously. When all the copper and iron wire ends are classified, the iron suction assembly 2 can be controlled to stop working.

[0026]The iron absorption assembly 2 includes a reduction motor 21...

Embodiment 2

[0031]On the basis of Example 1, such asfigure 1 ,Figure 4 ,Figure 5 withFigure 6 As shown, the sweeping assembly 4 is also included. The sweeping assembly 4 includes a rotating rod 41, a sweeping round shaft 42, a gear 43, a rack 44, a mounting seat 45, a guide rod 46 and a second compression spring 47, and a side plate There is a rotating rod 41 on the left side of 33. The center of the rotating rod 41 is equipped with a sweeping shaft 42. The front and rear sides of the rotating rod 41 are connected with gears 43. The left side of the side plate 33 is slidably equipped with racks. 44. The rack 44 meshes with the gear 43. The right side of the rack 44 is connected with a mounting seat 45. The mounting seat 45 is provided with a guide rod 46 in a sliding manner. The guide rod 46 is matched with the slide plate 25, and the guide rod 46 is connected to the mounting seat 45. A second compression spring 47 is connected therebetween.

[0032]When the sliding plate 25 moves to the left side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com