Film grabbing device

A grasping device and film technology, applied in packaging and other directions, can solve the problems of manpower and material resources, low production efficiency, etc., and achieve the effect of saving time, easy transportation, and no manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

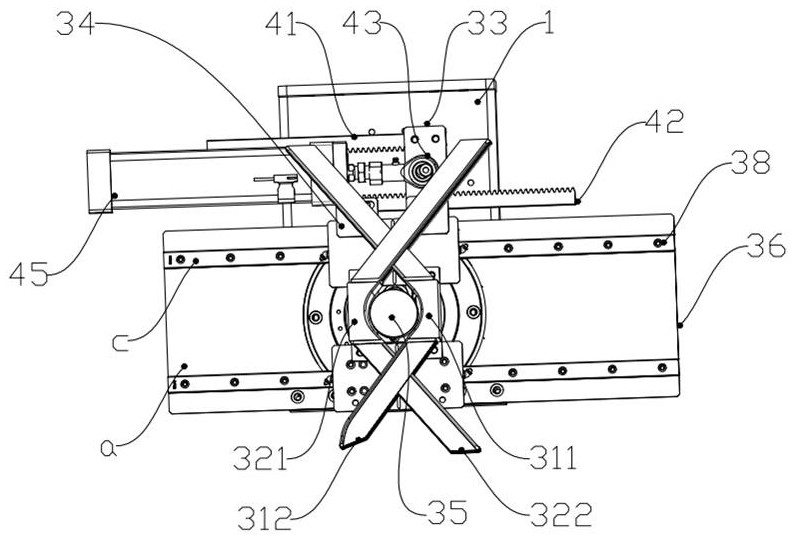

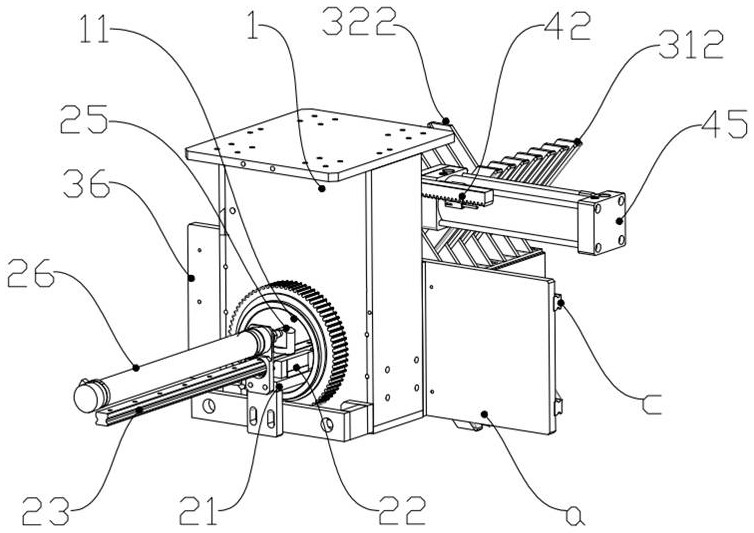

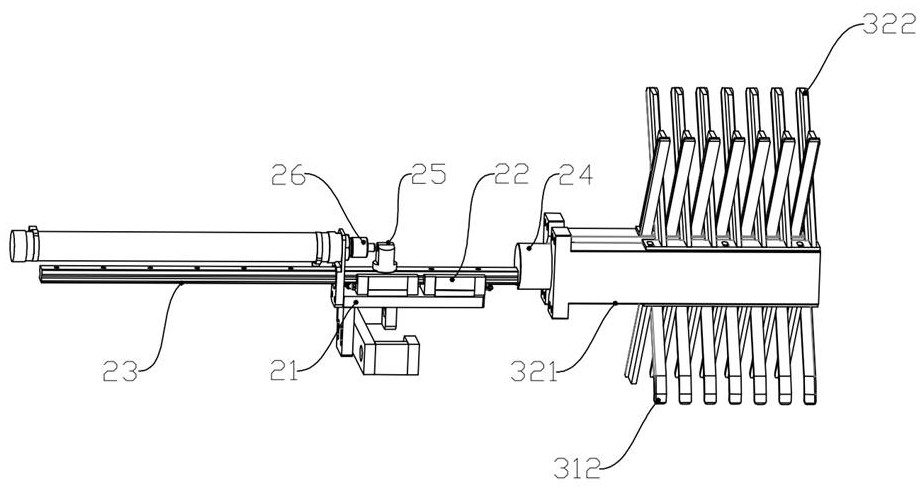

[0031] Such as Figure 1-10 As shown, a film grabbing device includes a base 1, a pushing device 2, a grabbing manipulator 3 and a driving device 4;

[0032] The base 1 is provided with a through hole 11, the pushing device 2 slides in the through hole 11, the grasping manipulator 3 is arranged on one side of the base 1, the driving device 4 is connected with the The grasping manipulator 3 is connected to drive the grasping manipulator 3 to grasp the film;

[0033] The grasping manipulator 3 includes a first gripper 31, a second gripper 32, a first connecting plate 33, a second connecting plate 34 and a hollow portion 35, and the top of the first connecting plate 33 is connected to the driving device 4 connection, the second connecting plate 34 is arranged on one side of the first connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com