Water heater and its control method

A water heater and controller technology, applied in water heaters, indirect heat exchangers, fluid heaters, etc., can solve the problems of long time for hot water and uneven temperature of water, achieve fast heat exchange and improve user experience The effect of feeling, temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

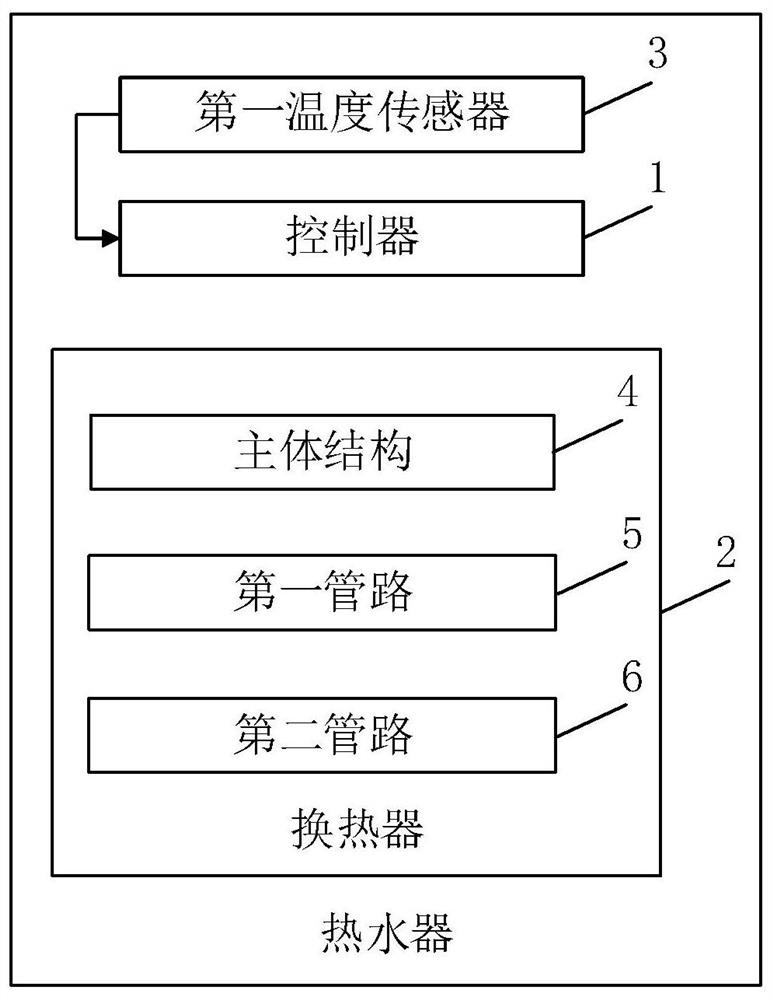

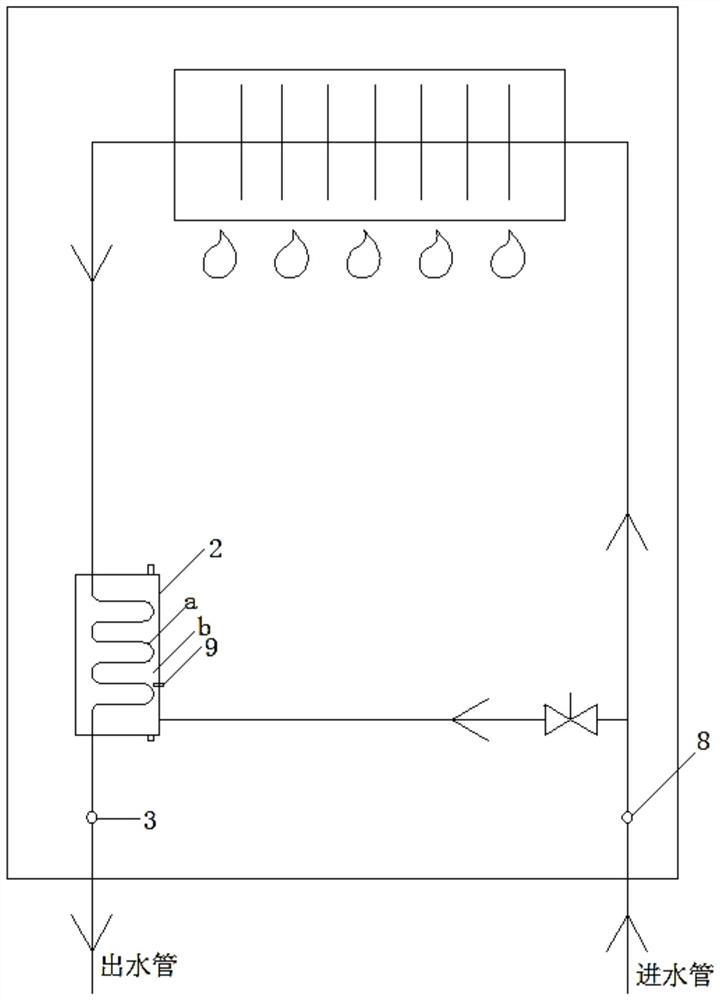

[0064] Such as figure 1 As shown, the water heater in this embodiment includes a controller 1 , a heat exchanger 2 and a first temperature sensor 3 .

[0065] Wherein, the heat exchanger 2 includes a main body structure 4, a first pipeline 5 and a second pipeline 6 that run through the main structure 4 and are independent of each other, the first pipeline 5 is arranged on the water outlet main pipeline of the water heater, and the second pipeline The channel 6 is used to store the buffer solution for heat exchange with the water flowing through the first pipeline 5 .

[0066] The first temperature sensor 3 is electrically connected to the controller 1, the first temperature sensor 3 is arranged at the water outlet end of the heat exchanger 2, and the first temperature sensor 3 is used to obtain the outlet water temperature and send it to the controller 1;

[0067] When the water heater is turned on for heating, the controller 1 is used to control the water heater to operate a...

Embodiment 2

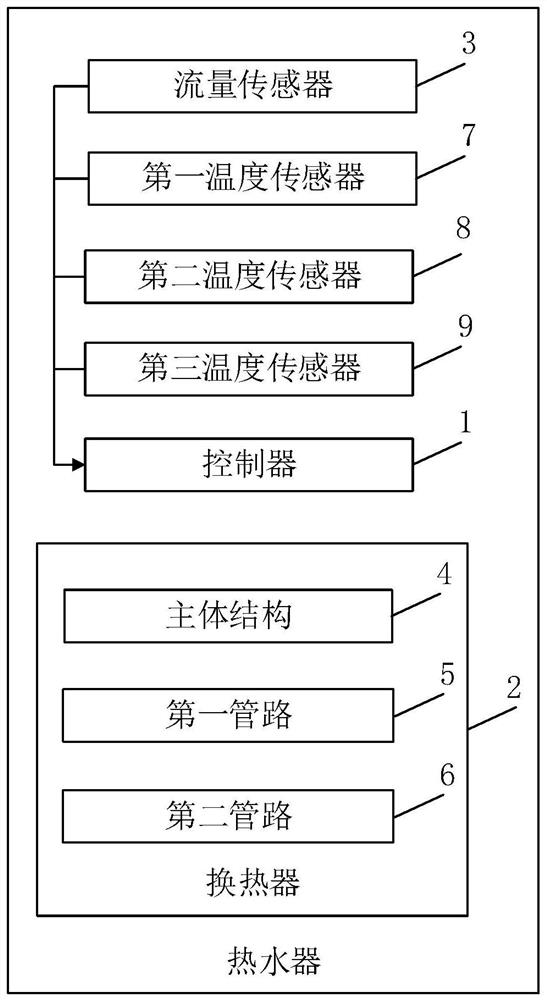

[0099] Such as Figure 4 As shown, the water heater of this embodiment is a further improvement to Embodiment 1, specifically:

[0100] In order to achieve a better temperature control effect of the outlet water, a heating module 10 is arranged in the heat exchanger 2 , the heating module 10 is arranged in the second pipeline, and the heating module 10 is electrically connected to the controller 1 .

[0101] When the water is turned on again after stopping the water for a set period of time, the controller 1 is used to control the heating module 10 to start heating the buffer in the second pipeline when the temperature of the buffer is lower than the set temperature; When the set temperature is reached, the heating module 10 is controlled to stop heating the buffer solution in the second pipeline.

[0102] Through the setting of the heating device, the temperature of the buffer solution is always kept at the preset buffer solution temperature, so as to ensure that the user ca...

Embodiment 3

[0116] Such as Figure 6 As shown, the water heater of this embodiment is a further improvement to Embodiment 1 or 2, specifically:

[0117] The main structure of the heat exchanger 2 in this embodiment includes a cover plate 12 , a bottom plate 13 , a plurality of first metal sheets 14 and a plurality of second metal sheets 15 .

[0118] The first metal sheet 14 and the second metal sheet 15 are stacked between the cover plate 12 and the bottom plate 13, and the cover plate 12 is covered on the bottom plate 13; in an optional embodiment, the first metal sheet 14 and the second metal sheet The metal sheets 15 are sequentially stacked between the cover plate 12 and the bottom plate 13 .

[0119] The cover plate 12 is provided with a buffer solution inlet hole P1, a user water inlet hole P2 and a user water outlet hole P3;

[0120] Wherein, the surface of each first metal sheet 14 is provided with a buffer flow channel 16, and each buffer flow channel 16 is in communication wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com