A transmission line live operation spanning device

A live operation and transmission line technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inability to be reused, and the inability to fold the spanning frame, so as to reduce labor costs, shorten the construction period, and increase the efficiency of installation and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

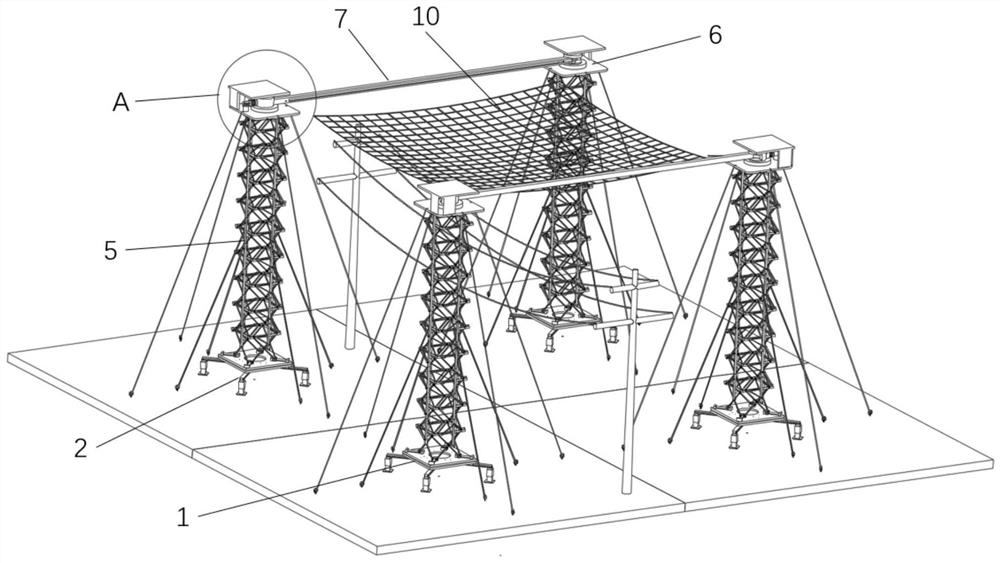

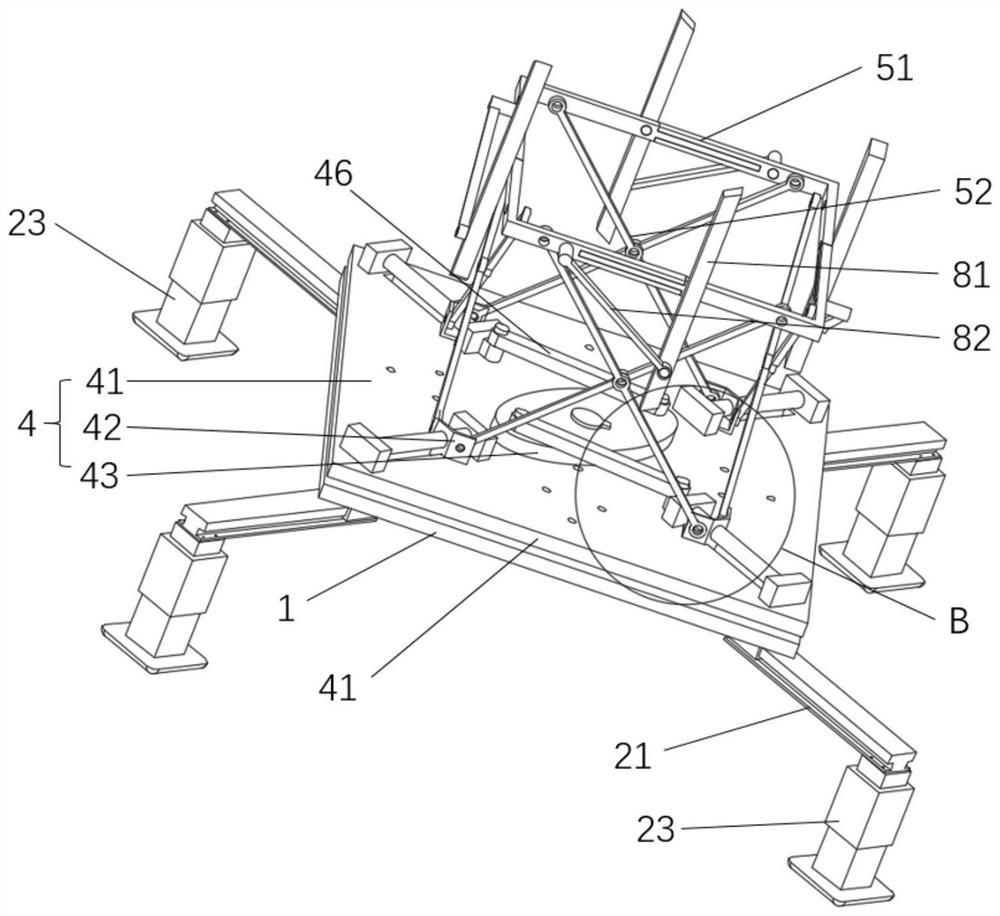

[0037] Such as Figure 1 to Figure 13As shown, the present invention provides a live operation spanning device for transmission lines, which includes several bases 1, and the bottom of the bases 1 is provided with a horizontal adjustment device 2; further, there are four bases 1, and the four bases 1 are respectively provided with Level adjustment device 2, to adjust the balance of the spanning device through four level adjustment devices 2, thereby improving the support strength of the spanning device; the base 1 is provided with a driving assembly 3 and a folding mechanism 4, and the driving assembly 3 and the folding mechanism 4 Connect; the folding mechanism 4 is hinged with a cross-type lifting mechanism 5, so as to drive the folding mechanism 4 through the drive assembly 3 to drive the cross-type lifting mechanism 5 to carry out lifting movement; the top of the cross-type lifting mechanism 5 is hinged with a top cover 6 The top cover 6 is rotatably provided with a spanni...

Embodiment 2

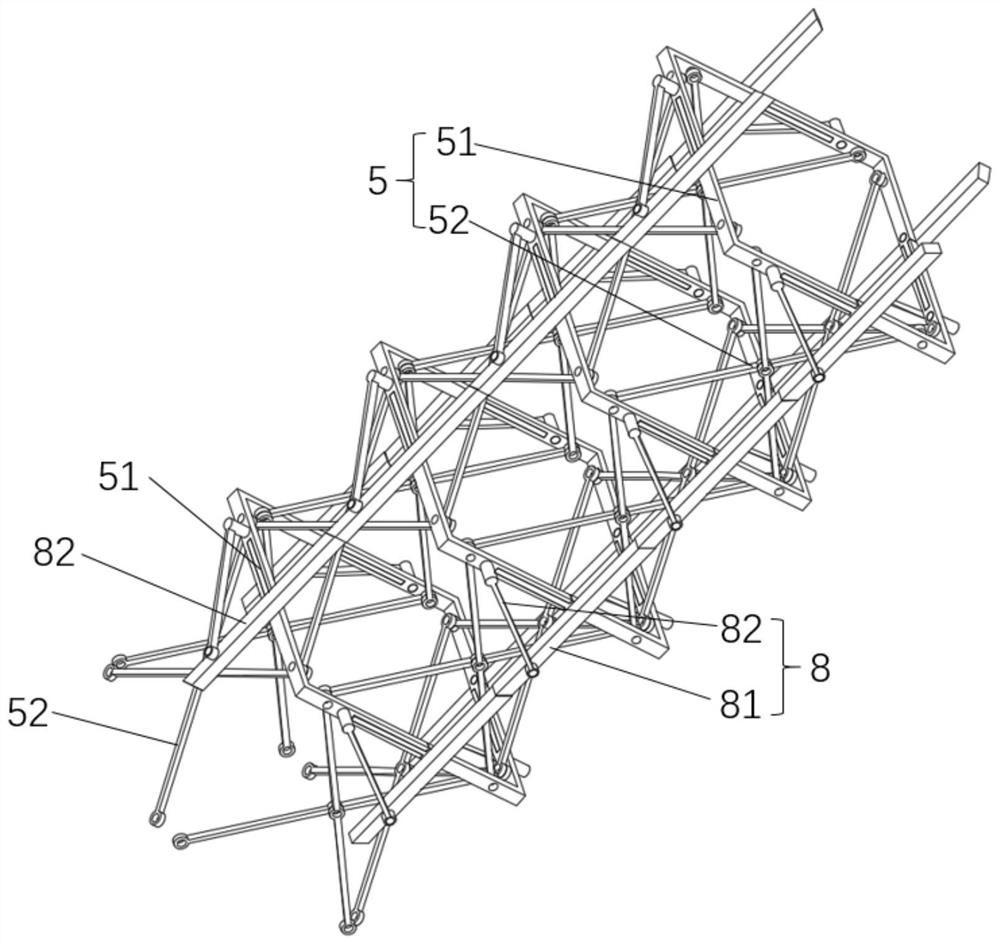

[0040] Such as Figure 1 to Figure 8 As shown, in combination with the technical solution of Embodiment 1, in this embodiment, the cross-type lifting mechanism 5 includes several horizontally telescopic rectangular frames 51 and hinged cross bars 52 that can rotate around the center. Rods 52 are connected; when the hinged cross bar 52 rotates around its center, the rectangular frame 51 will be opened or contracted to realize the change of its horizontal area, thereby realizing the adjustment of the vertical distance between the multiple rectangular frames 51 to Realize the lifting function of the cross-type lifting mechanism 5; adopt the above-mentioned scheme, can effectively improve the telescopic amount and telescoping speed of the cross-type lifting mechanism 5, greatly speed up the construction efficiency of the spanning device; further, four cross-type lifting mechanisms 5 can be Realize the folding and spreading of 15-20m, and can span the 110kv line at a distance of 15...

Embodiment 3

[0048] Such as Figure 10 and Figure 11 As shown, in combination with the technical solution of Embodiment 2, in this embodiment, a stepper motor 61 and a turntable 62 are provided on the top cover 6, and the output end of the stepper motor 61 is connected to the turntable 62; specifically, the turntable 62 can be moved through the bearing The rotation is provided on the top cover 6, and a circle of teeth is provided on the turntable 62. The stepping motor 61 engages with the turntable 62 through the gear, so as to drive the turntable 62 to rotate through the stepping motor 61; one end of the span rod 7 is connected to the turntable 62 Above, the spanning rod 7 is driven by the rotation of the turntable 62 to rotate at an angle of 0-90°, thereby realizing the connection of the cross-type lifting mechanism 5 on both sides of the transmission line; one end of the spanning rod 7 is rotatably provided with a driving wheel 63, and the spanning rod The other end of 7 is rotatably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com