High-voltage wiring harness branching equipment for new energy automobile

A technology for new energy vehicles and high-voltage lines, which is applied to vehicle components, electrical components, circuits or fluid pipelines, etc. It can solve problems such as easy dust entry at joints, easy damage to the outer skin of lines, and no protective measures for branching joints. Reduce the probability of accidental contact with the outgoing line, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

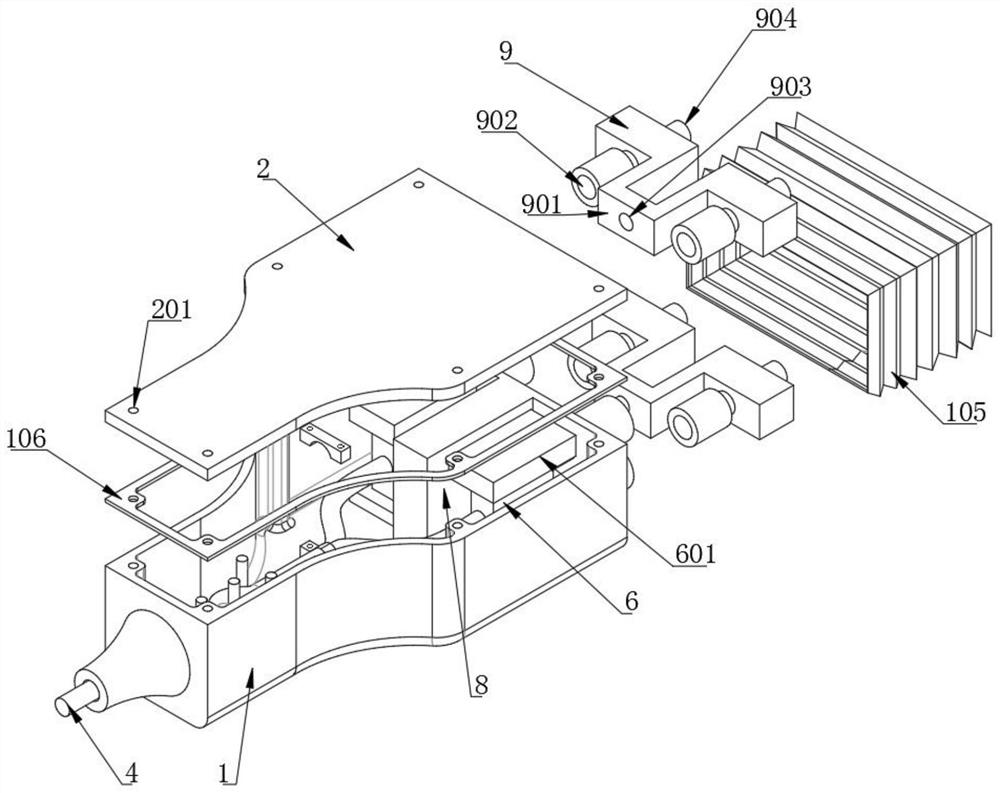

[0030] Please refer to the attached Figure 1-6 , a high-voltage wire harness branching device for new energy vehicles, comprising: a bottom case 1, a protective cover 105 and a wire seat 9.

[0031] Wherein, the end of the bottom case 1 is welded with a wire end protection seat 3, a winding post 104 is arranged at the bottom of the bottom case 1, an insulating plate 8 is arranged at the top of the bottom case 1, and an outlet protection tube 701 is welded at the top of the bottom case 1;

[0032] A protective cover 105 is bonded to the top edge of the bottom case 1, the outlet protection tube 701 is located inside the protective cover 105, and the top of the bottom case 1 is equipped with a cable seat 9;

[0033] Both ends of the wire base 9 are welded with a wire base plug 902 , the wire base plug 902 is socketed in the outlet protection tube 701 , and the wire base 9 is located inside the protective cover 105 .

[0034] In a further embodiment, the bottom case 1 can protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com