Spiral winding device of strength training machine and strength training machine

A spiral winding and training machine technology, applied in the field of strength equipment, can solve the problems of affecting the training effect, the change of the exit angle of the pull rope A3, and the inability to achieve the training effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

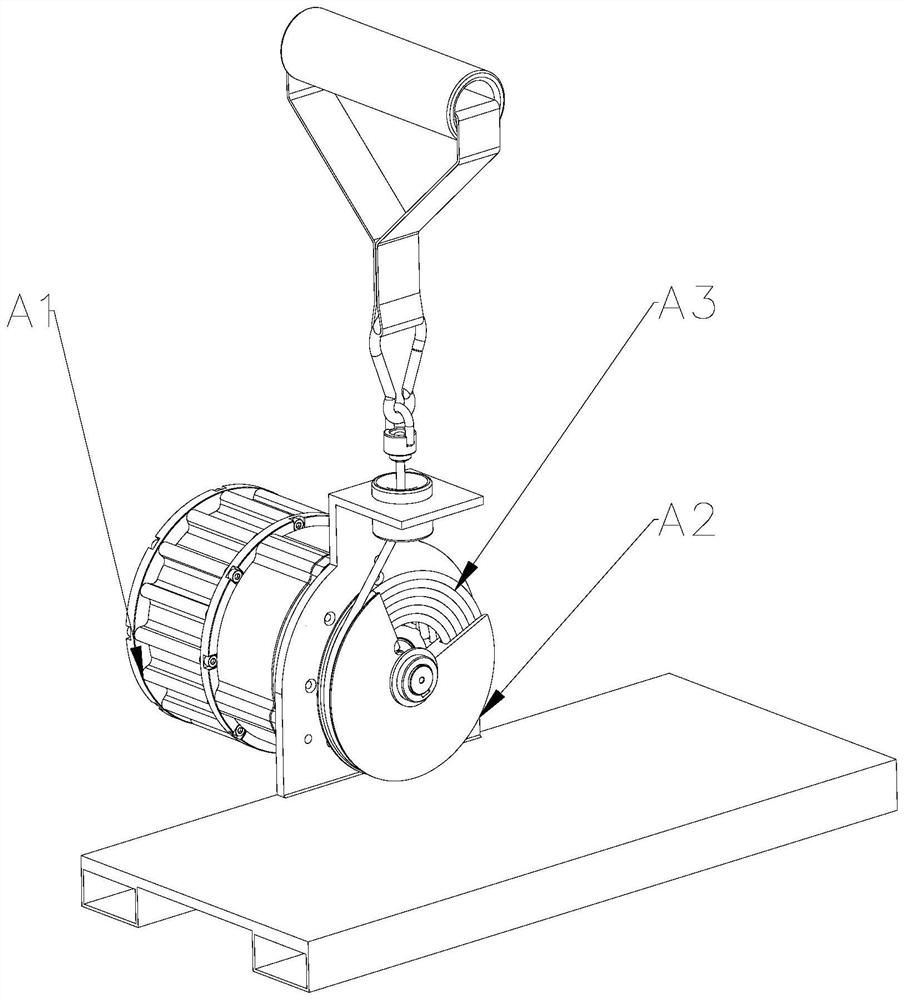

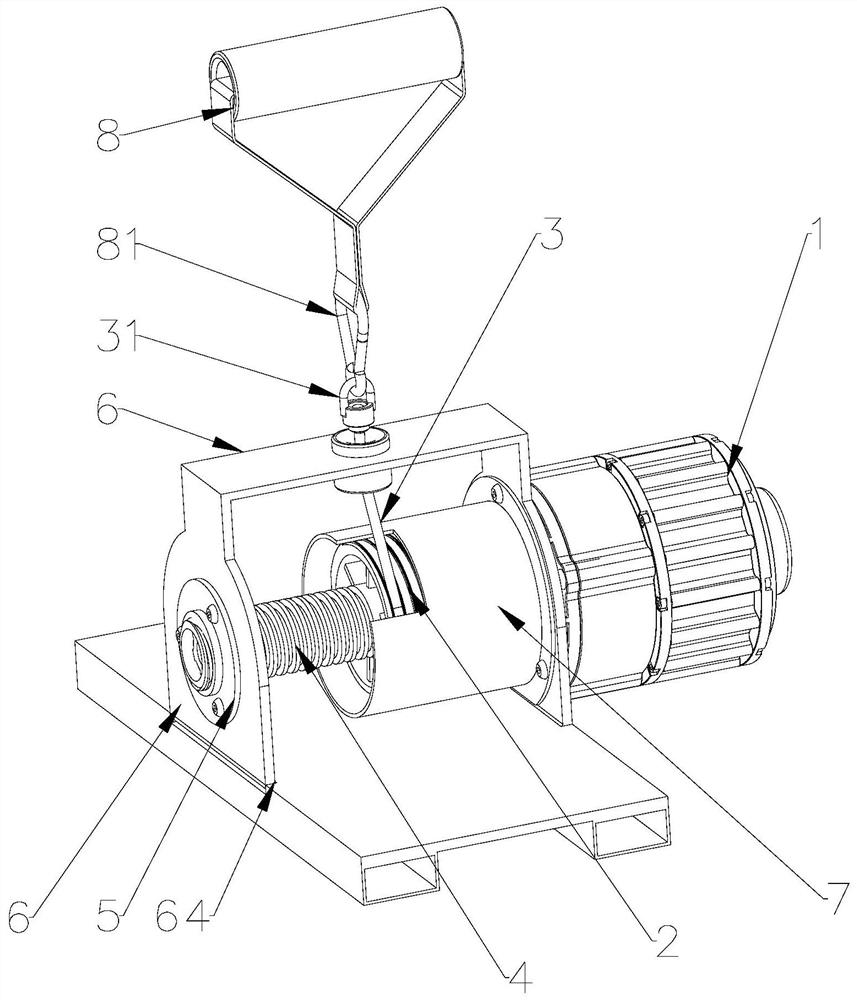

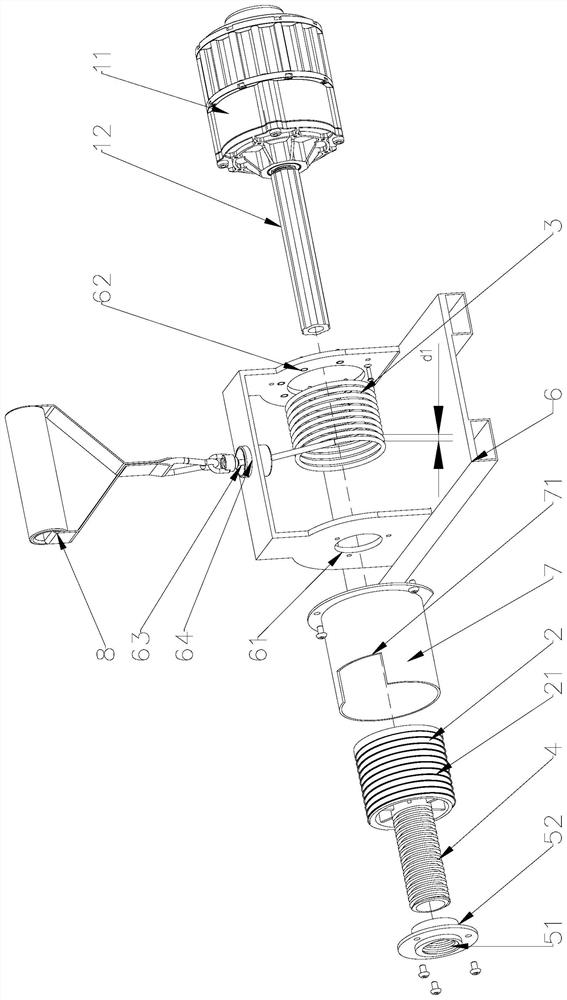

[0027] Such as figure 2 and image 3 As shown, this embodiment provides a helical winding device for a strength training machine, which includes the resistance source 1 , the winding wheel 2 , the flexible connector 3 , the screw 4 and the mounting frame 6 .

[0028] The resistance source 1 includes a resistance source body 11 and an output shaft 12 , and the resistance source 1 outputs torque through the output shaft 12 .

[0029] The reel 2 is cylindrical, and grooves 21 are provided on its side, and the grooves 21 are arranged in a spiral shape along the side of the reel 2 . One end of the flexible connecting member 3 is fixed on the reel 2 , and the flexible connecting member 3 is accommodated in the groove 21 and rotates on the reel 2 along the groove 21 one by one. One end of the reel 2 is sleeved on the output shaft 12, and the other end is fixedly connected with the screw rod 4, and the reel 2, the screw rod 4 and the output shaft 12 are coaxial.

[0030] The mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com