Envelope machine gluing device with good gluing effect

A gluing device and gluing technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve problems such as low work efficiency, easy sticking of objects on the gluing strip, and difficulty in detaching from the gluing strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

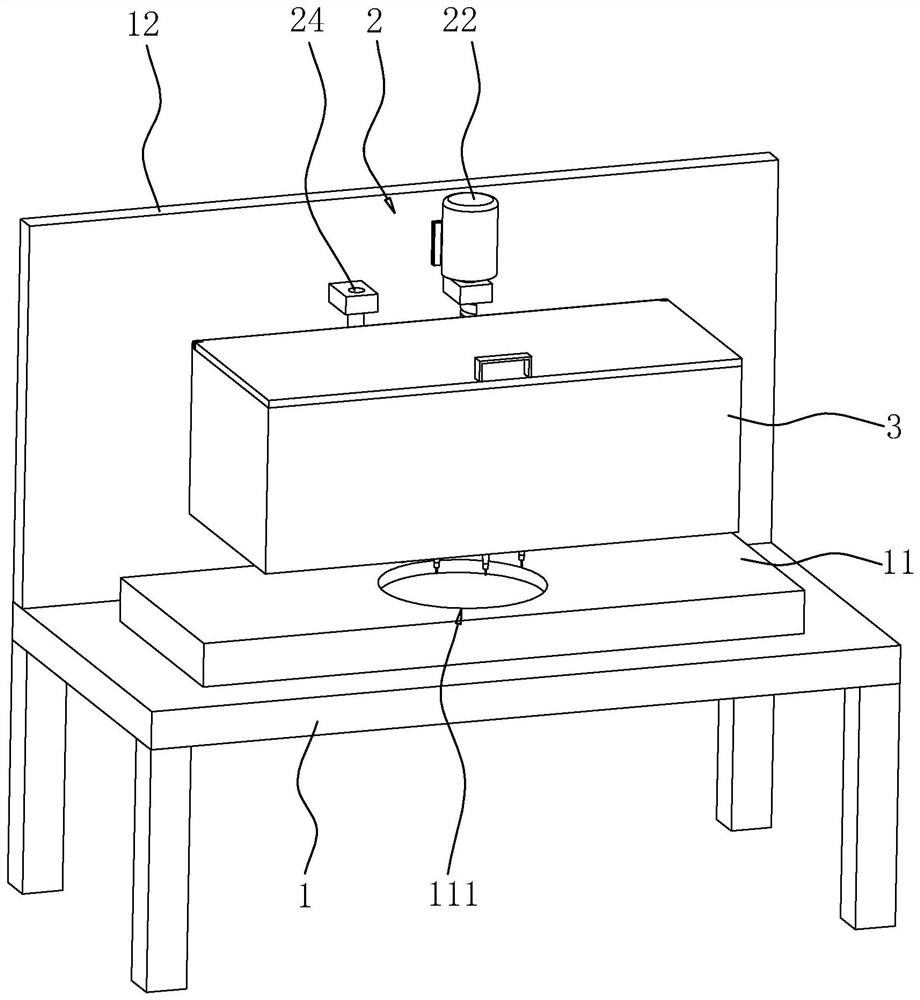

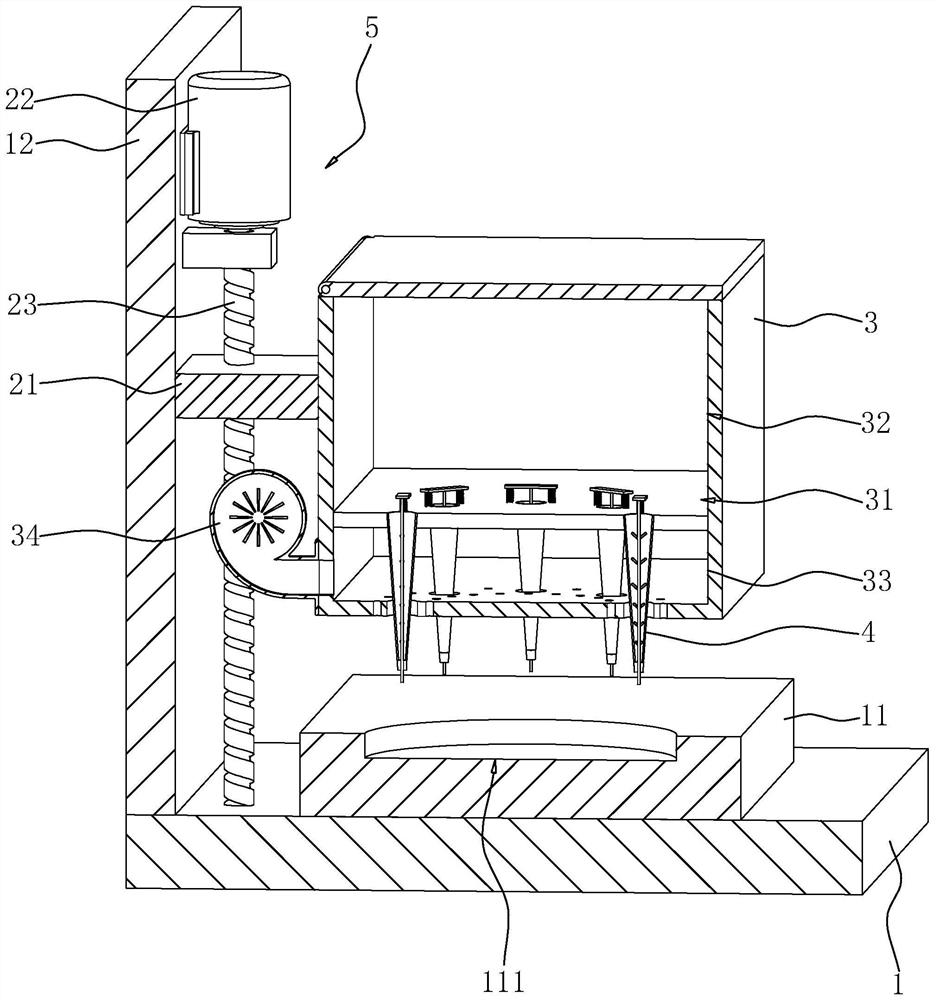

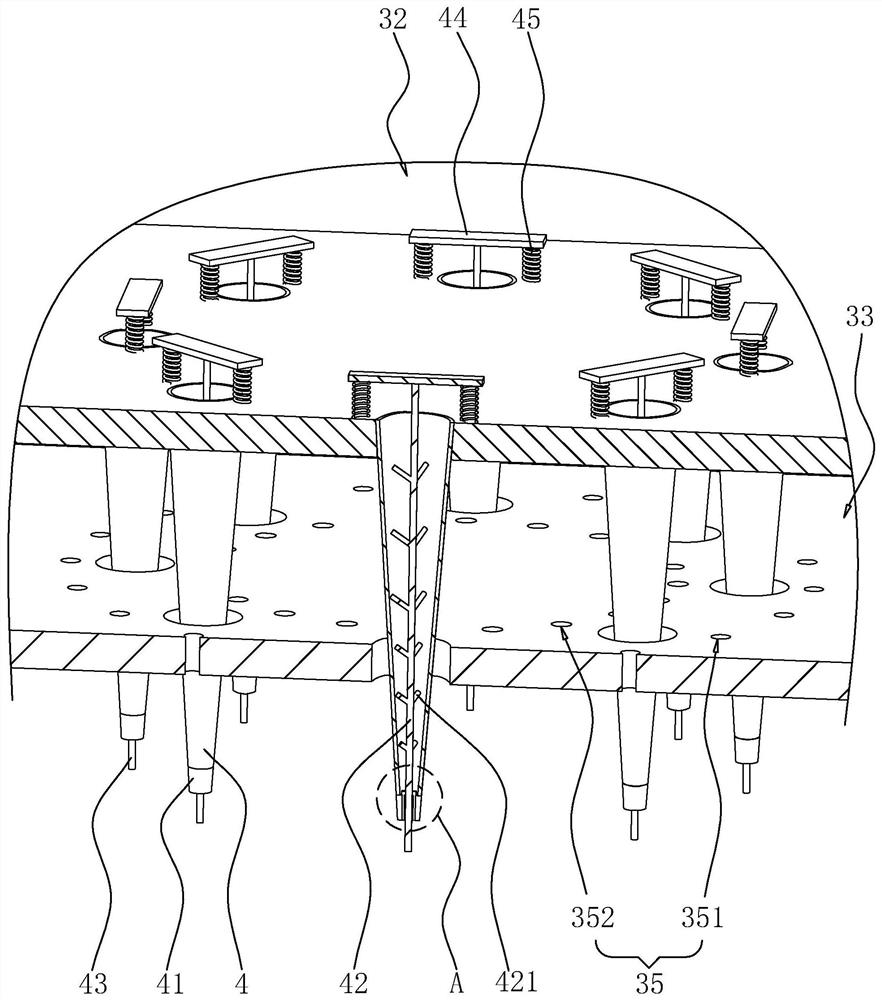

[0032]The following is attachedFigure 1-4Give further details on this application.

[0033]The embodiment of the application discloses a gluing device for an envelope machine with better gluing effect. Referencefigure 1 , The gluing device includes a support frame 1, and the upper surface of the support frame 1 is fixedly connected with a placing plate 11 for holding objects. The upper surface of the support frame 1 is fixedly connected with a support plate 12 arranged vertically upward at a position close to the side of the support frame 1. The support plate 12 is provided with a mounting box 3 on the side close to the support frame 1, and the support plate 12 is connected with a device that drives the mounting box 3 to lift. Lifting mechanism 2.

[0034]Referencefigure 2 , The inside of the installation box 3 is fixedly connected with a horizontal partition plate 31, and the partition plate 31 divides the inside of the installation box 3 into a glue storage cavity 32 and a transition ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com