Packaging and shaping device for coolant

A shaping device and cold storage agent technology, applied in the field of modern logistics, can solve the problems of uneven heating expansion, easy damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

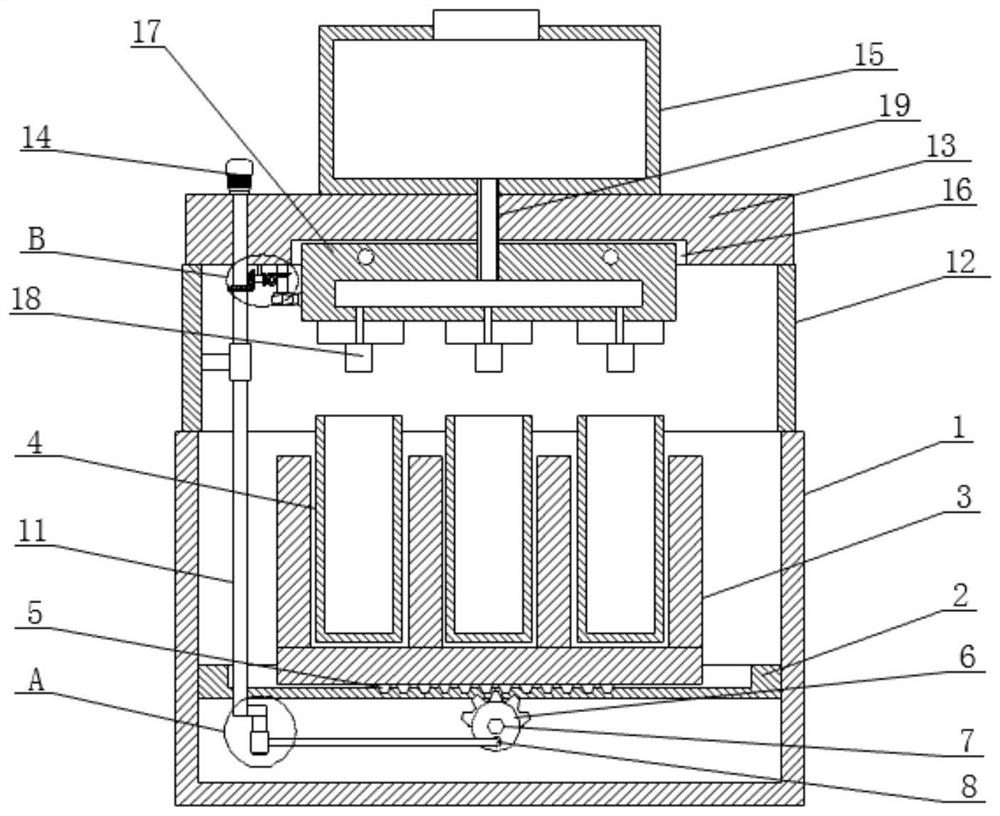

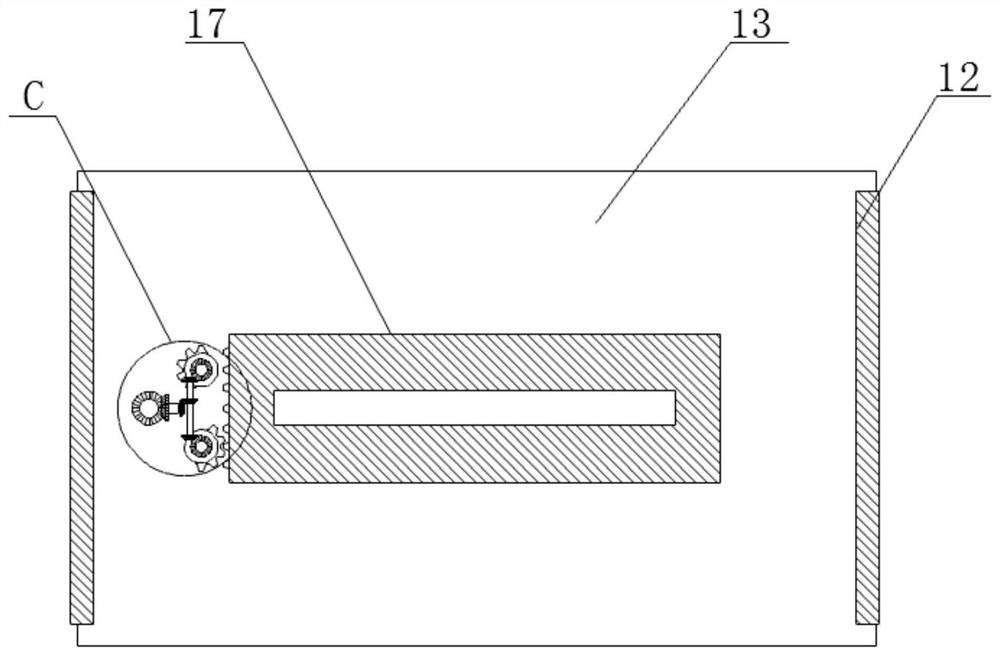

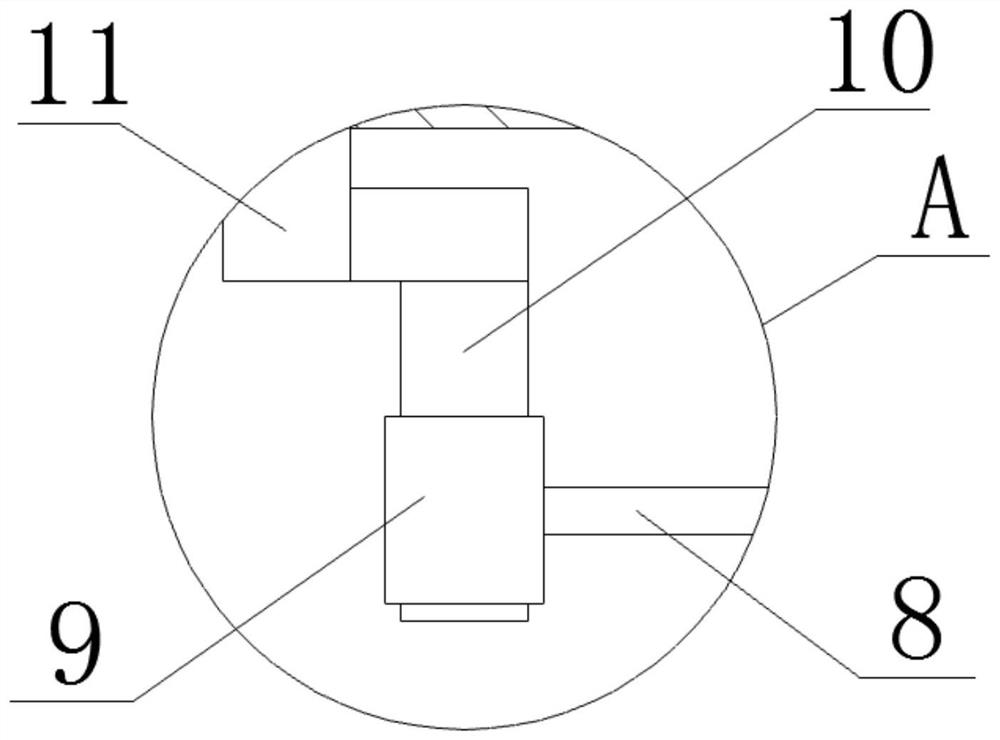

Embodiment 1

[0025] refer to Figure 1-5 , a packaging and shaping device for cold storage, comprising a packaging box 1, the packaging box 1 is in the shape of a cuboid or a cube, the packaging box 1 is fixedly connected with a partition 2, the partition 2 is slidingly connected with a shaping box 3, and the inside of the shaping box 3 A plurality of sizing boxes 4 are placed, and each sizing box 4 can be stuck in a respective groove in the sizing box 3 to avoid shaking. The interval between the sizing boxes 4 can be made of heat insulating material, preferably soft material such as foam, and the foam can be The heat insulation can also buffer shaking. The bottom of the shaping box 3 is fixedly connected with the first rack 5, the first rack 5 is meshed with the first sector gear 6, and the first sector gear 6 is fixedly sleeved with the first roller 7. The first roller shaft 7 is rotatably connected in the packaging box 1, the first sector gear 6 is hingedly connected with a connecting r...

Embodiment 2

[0034] refer to Figure 1-5 , a packaging and shaping device for cooling agent, comprising a packaging box 1, the packaging box 1 is in the shape of a cuboid or a cube, the packaging box 1 is fixedly welded with a partition 2, the partition 2 is slidingly connected with a shaping box 3, and the shaping box 3 A plurality of sizing boxes 4 are placed, and each sizing box 4 can be stuck in a respective groove in the sizing box 3 to avoid shaking. The interval between the sizing boxes 4 can be made of heat insulating material, preferably soft material such as foam, and the foam can be Heat insulation can also buffer shaking. The bottom of the shaping box 3 is fixedly welded with the first rack 5, the first rack 5 is meshed with the first sector gear 6, and the first sector gear 6 is fixedly sleeved with the first roller 7. The first roller 7 is rotatably connected in the packaging box 1, the first sector gear 6 is hingedly connected with a connecting rod 8, and one end of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com