Novel ceramsite backfilling method

A new type of ceramsite technology, applied in soil protection, on-site foundation soil survey, construction, etc., can solve the problems of inability to compact ceramsite and meet the requirements of ceramsite backfill, etc., and achieve good compaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] The present invention will be described below in conjunction with the backfilling of the ceramsite layer in the molten salt cold tank of the 950MW photothermal photovoltaic hybrid power station in Dubai. The foundation radius of molten salt cold tank of Dubai 950MW photothermal photovoltaic hybrid power station is 22.5m, and the inside is graded sand and ceramsite from bottom to top (thickness is 1.5m, area is about 1600m 2 ), gravel layer.

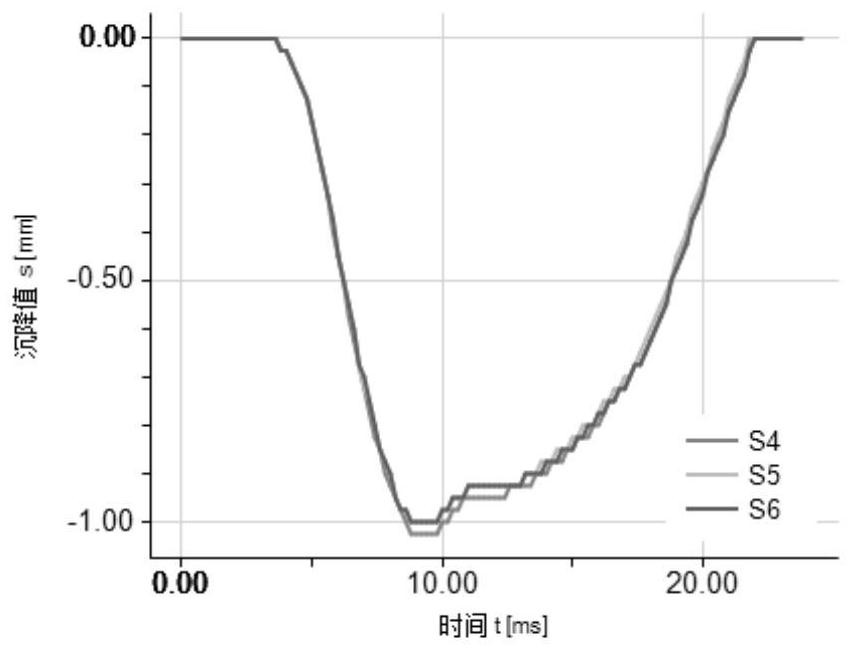

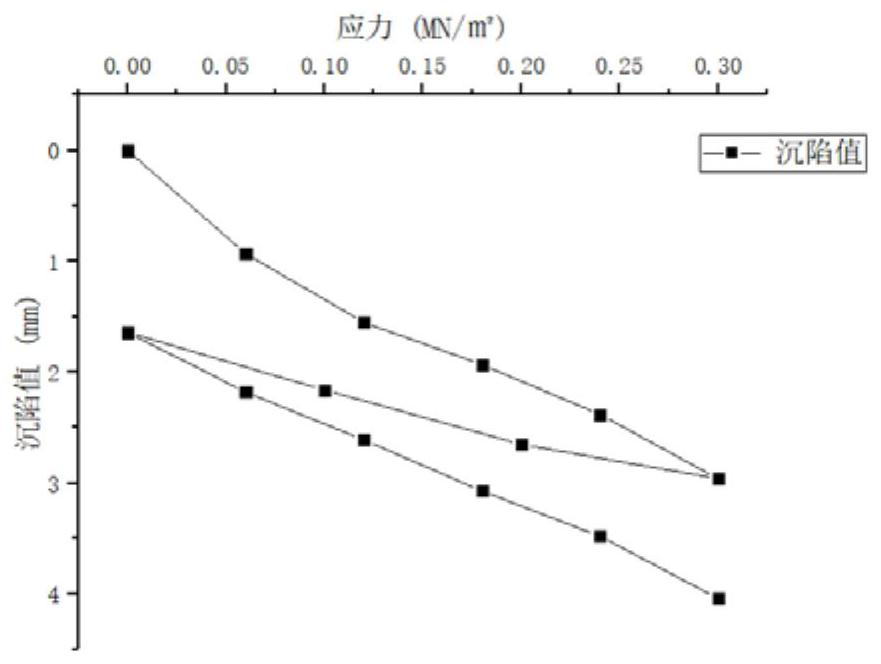

[0014] The particle size of the ceramsite used in the present invention is not more than 20mm, and the density is 340kg / m 3 , The compression rate of the ceramsite soil layer is 13%-17%. In order to achieve the required compressibility, the compaction of the ceramsite soil layer requires a lot of time and human and mechanical input. If the compression rate is too large, such as greater than 17%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com