Self-locking wire pressing device for weak current engineering cable wiring

A technology of weak current engineering and crimping device, which is applied in the direction of electrical components, etc., can solve the problems of easy entanglement of cables and achieve the effects of improving efficiency and accuracy, preventing bending and entanglement, and good wiring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

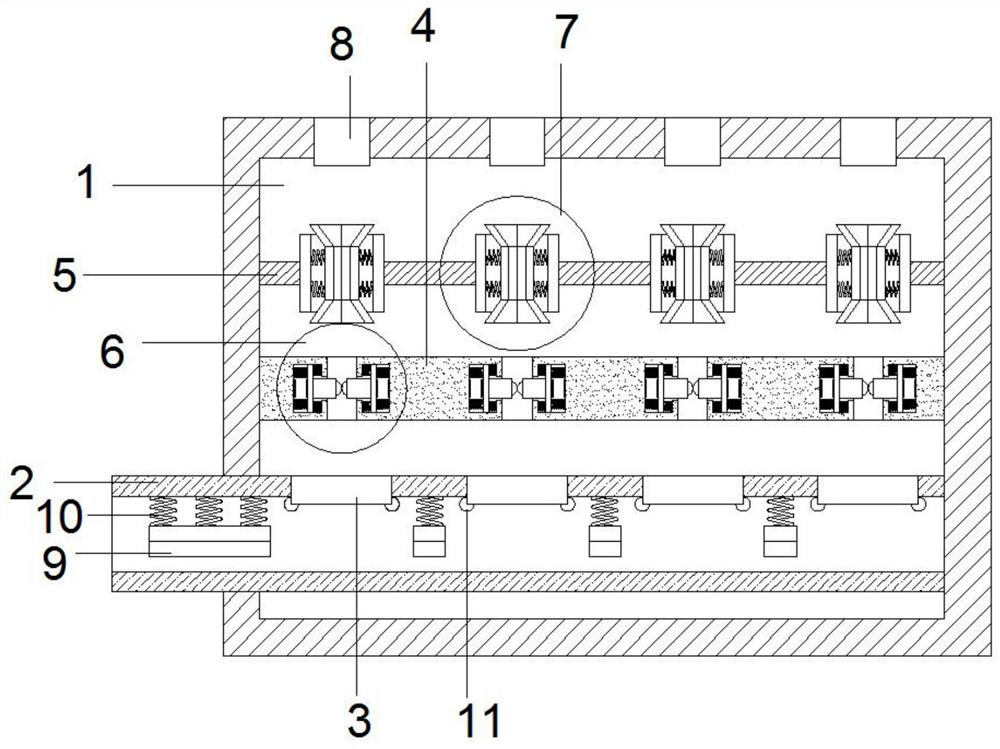

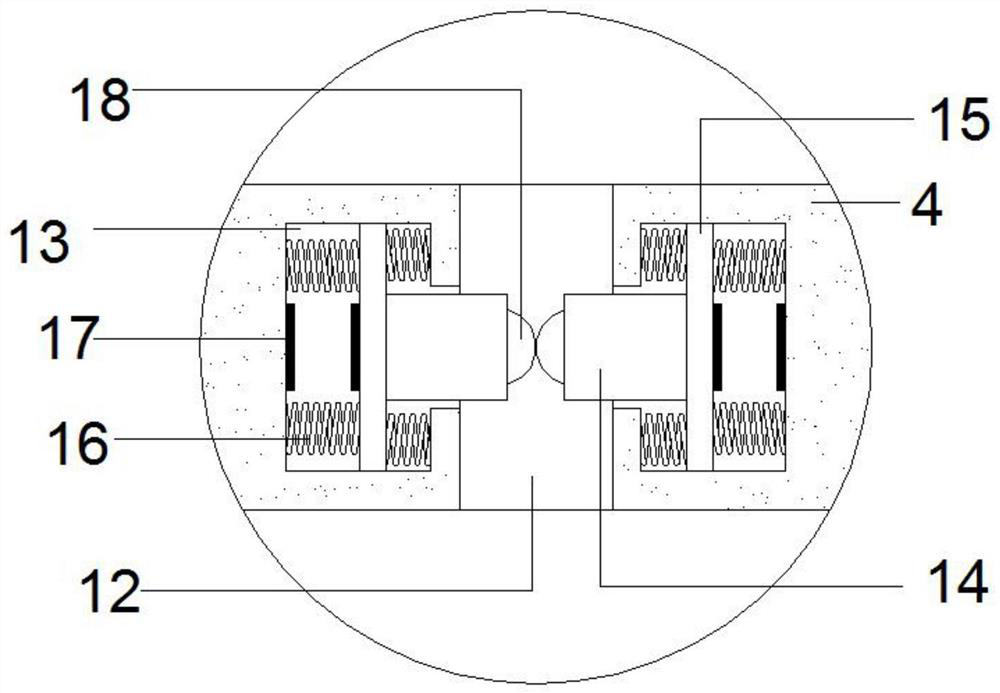

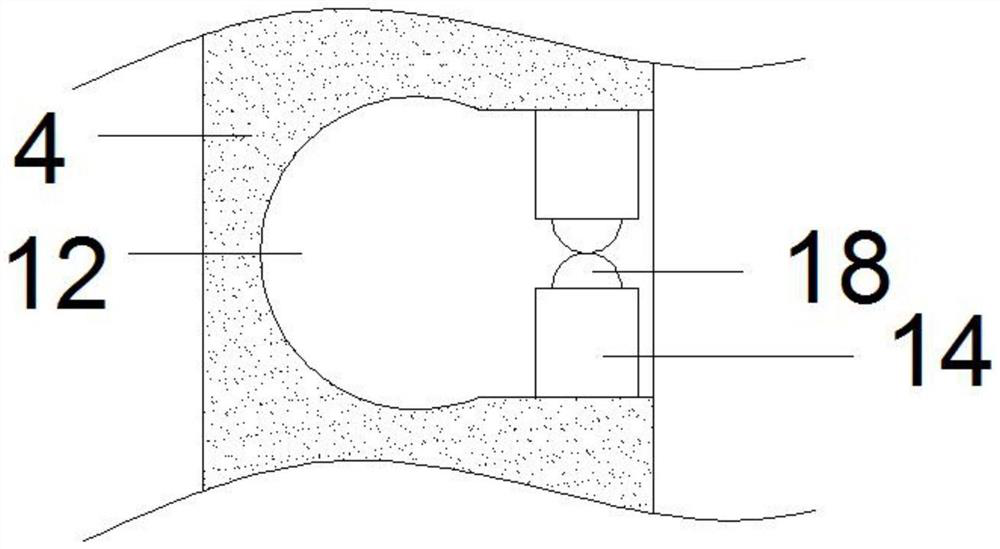

[0028] refer to Figure 1-6 , a self-locking crimping device for cable wiring in weak current projects, comprising a device box 1, a wire inlet pipe 2 arranged at the lower end of the device box 1 and a plurality of wire outlets 8 arranged at the top of the device box 1, the wire inlet pipe A plurality of cable management openings 3 are opened above 2, and the two ends of the connection plate 4 are connected with the inner side wall of the device box 1 and arranged directly above the line inlet pipe 2, and a plurality of first locking mechanisms 6 are arranged on the connection plate 4, The first thread locking mechanism 6 includes a wire slot 12 provided on the connecting plate 4. The inner side of the wire slot 12 is arc-shaped, and the outer side is a square opening shape. The opening of the wire slot 12 is symmetrically opened with T-shaped Slot 13, one end of extrusion block 14 is inserted into the T-shaped slot 13 and connected with the limiting plate 15, and the limitin...

Embodiment 2

[0030] Such as Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. In order to improve the smoothness of the placement of the main cable inside the wire inlet pipe 2, preferably, a plurality of wire crimping plates 9 are arranged inside the wire inlet pipe 2 to crimp the wires. The plate 9 is connected with the upper end of the inlet pipe 2 through the first elastic member 10 .

[0031] In order to further improve the stability of the fixing of the total cable, preferably, the wire pressing plate 9 is in an inverted arc shape.

Embodiment 3

[0033] Such as Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. In order to prevent the cables from being scratched by the side of the cable management port 3 when they are pulled out from the side of the cable management port 3, preferably, the two sides of the cable management port 3 are arranged symmetrically. There are rollers 11, and the rollers 11 are rotatably connected with the cable management port 3.

[0034] In order to facilitate the entry of cables into the wire slot 12 and prevent damage to the cables, preferably, balls 18 are provided at the adjacent ends of the two symmetrical extrusion blocks 14 , and the balls 18 are rotatably connected to the extrusion blocks 14 .

[0035] In order to improve the extrusion stability of the extruding block 14 , preferably, two magnet blocks 17 of the same polarity are arranged symmetrically adjacent to the limiting plate 15 and the T-shaped slot 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com