A kind of preparation method of continuous fiber resin matrix composite material fastener

A continuous fiber and composite material technology, applied in the field of resin-based composite material preparation, can solve the problems of thread formation, insufficient mechanical properties, weak transverse strength of continuous fiber, etc., and achieve the effect of high yield and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

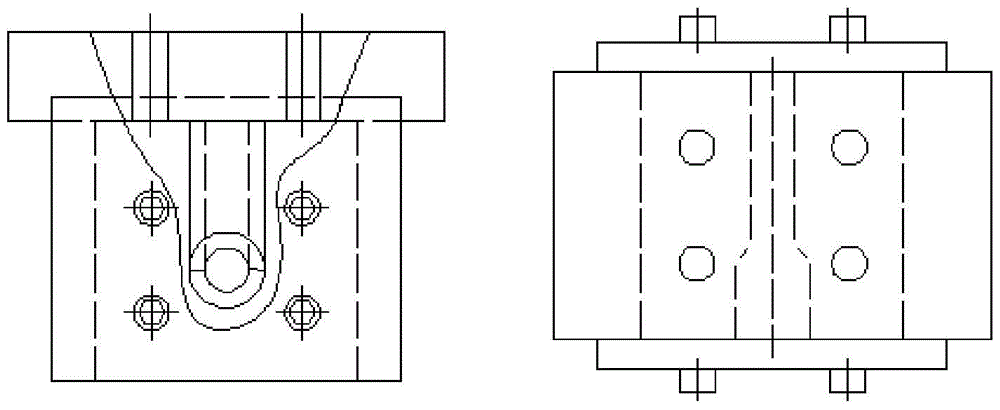

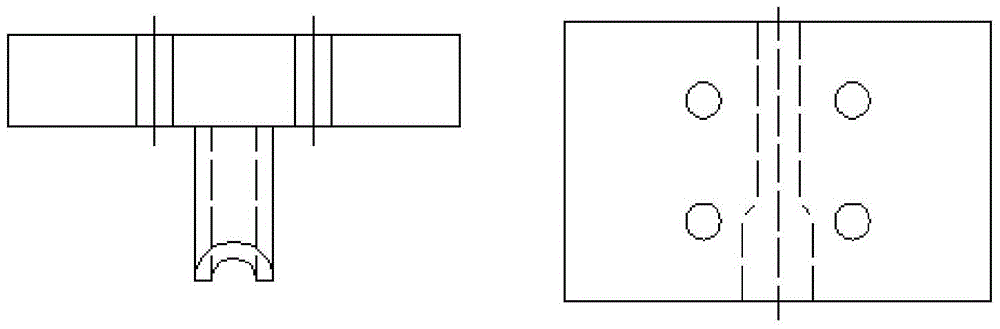

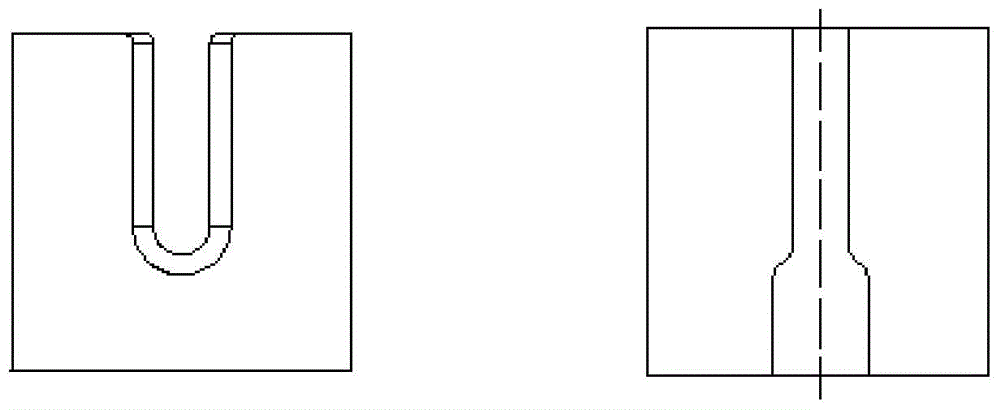

Image

Examples

Embodiment 1

[0031] Preparation of M6 hex head bolts

[0032] Prepare M6*15 hexagon head bolt fasteners with a strength above 200MPa, weave a bundle of 3K carbon fibers (single filament diameter 7μm) and 16 polyetheretherketone resin filaments (single filament diameter 0.15mm) into a composite filament, and control the carbon fiber The volume ratio is 28.5%. According to the size of M6 hex head bolts (various size parameters can be obtained by referring to the fastener standards of relevant specifications), determine the size of each part of the intermediate bar, that is, the volume of the large head is about 346.2mm 3 , the height of the big head is 8mm, and the volume of the thin rod (threaded rod plus threaded part) is about 332.9mm 3 , the diameter of the thin rod is 4.4 mm, the height of the intermediate rod is 30 mm, and then 56 composite wires are cut with a length of 30 mm. Put the intercepted composite wire into a preforming mold made according to the size of the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com