Adjustable anti-galloping spacer

A spacer and anti-galling technology, which is applied in the direction of mechanical vibration attenuation devices, devices for maintaining the distance between parallel conductors, electrical components, etc., can solve problems affecting workers' construction, adjustment of relative positions of spacers, and extension of construction period, etc., to achieve the suppression of the same period Dancing and non-synchronous dancing, stronger connection structure, firm and stable connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

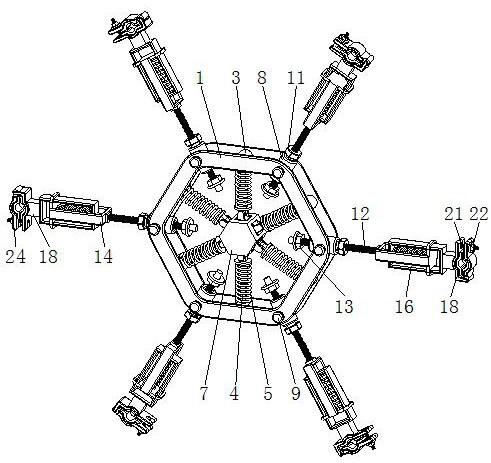

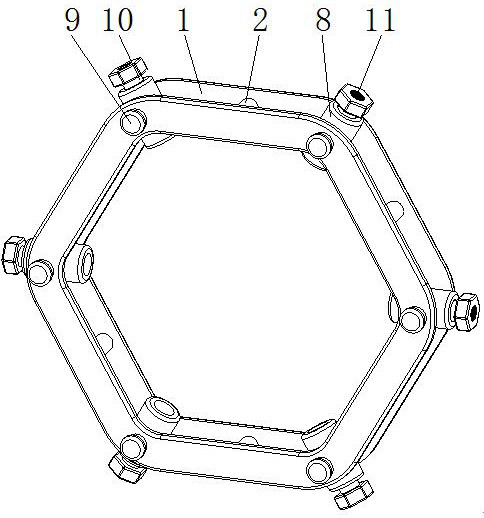

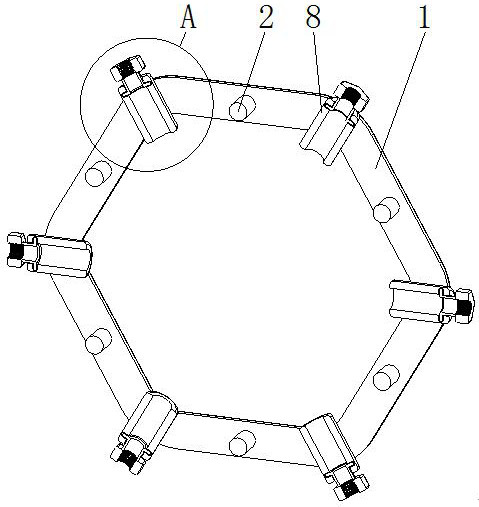

[0026] see Figure 1-6 , the present invention provides a technical solution: an adjustable anti-galling spacer, including a spacer body 1, a fixed rod 2 is fixedly installed inside the spacer body 1, and a sleeve ring block is movably socketed on the outside of the fixed rod 2 3. The bottom of the sleeve ring block 3 is fixedly installed with a telescopic sleeve rod 4, and the outer movable sleeve of the telescopic sleeve rod 4 is connected with an anti-galling spring 5, and the bottom of the telescopic sleeve rod 4 is movably installed with a movable base 6, and the bottom of the movable base 6 A fixed center block 7 is fixedly installed, and a socket pipe 8 is installed movable inside the spacer body 1, and the inner movable socket of the socket pipe 8 is connected with a limit inner ring 10, and the end of the limit inner ring 10 away from the socket pipe 8 is fixedly installed with an adjustment Nut 11, the internal movable socket of adjusting nut 11 is provided with thre...

Embodiment 2

[0029]On the basis of Embodiment 1 of the present invention, there are two spacer rod bodies 1, six fixed rods 2, six fixed rods 2 are fixedly installed between the two spacer rod bodies 1 in the form of a circle, and six movable bases 6 , the six movable bases 6 are fixedly installed on the outside of the fixed center block 7 in the form of a circle, and there are six socket ring blocks 3, and the six socket ring blocks 3 are respectively movably socketed on the outside of the six fixed rods 2, and the socket pipe 8 Extension rods 9 are fixedly installed at both ends of the two extension rods 9. One end of the two extension rods 9 away from the socket pipe 8 respectively penetrates the two spacer rod bodies 1 and extends to the outside. There are six socket pipes 8, and the six socket pipes 8 are in a circular motion. Installed between the two spacer rod bodies 1, the inside of the sleeve pipe 8 is provided with a rotating groove that matches the specification and size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com