Plastic-coated rotor, motor and fan

A technology of overmolding and rotors, applied in the fields of motors, ventilators, and overmolded rotors, can solve the problems of high technological requirements, difficult shaft sleeve processing, poor reliability, etc. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

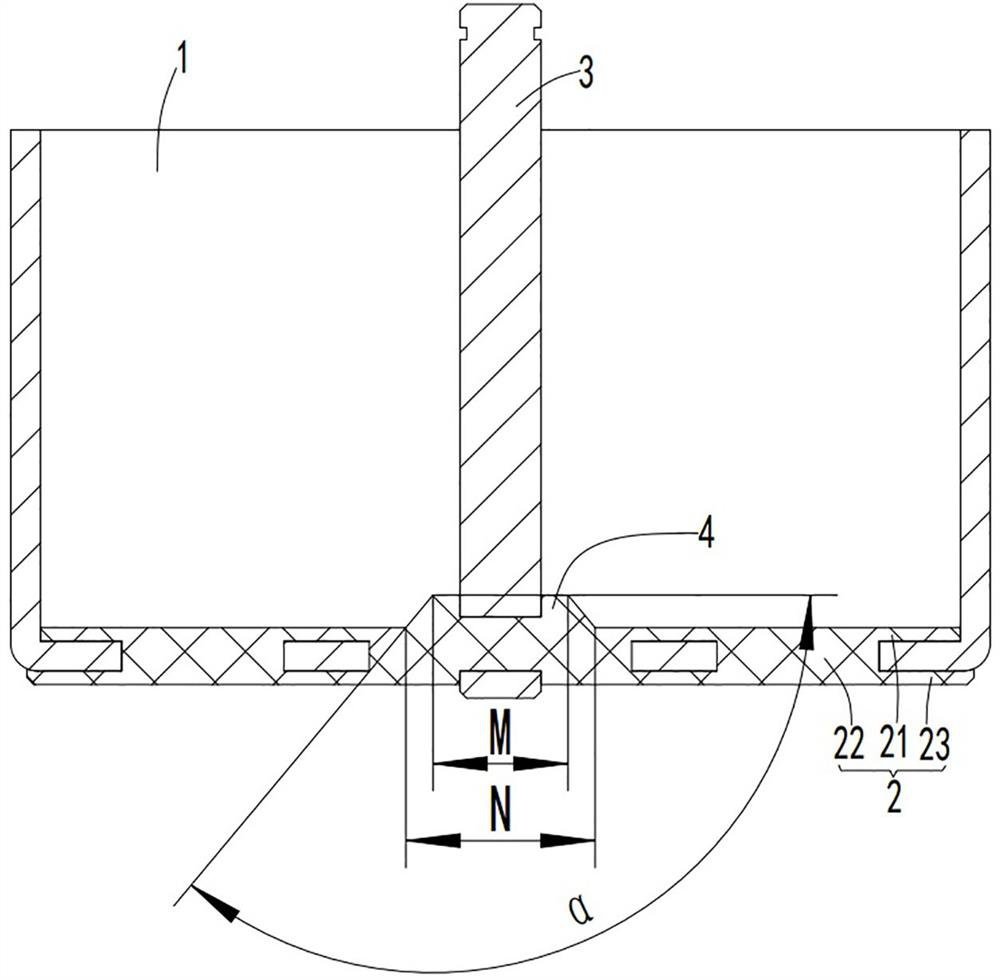

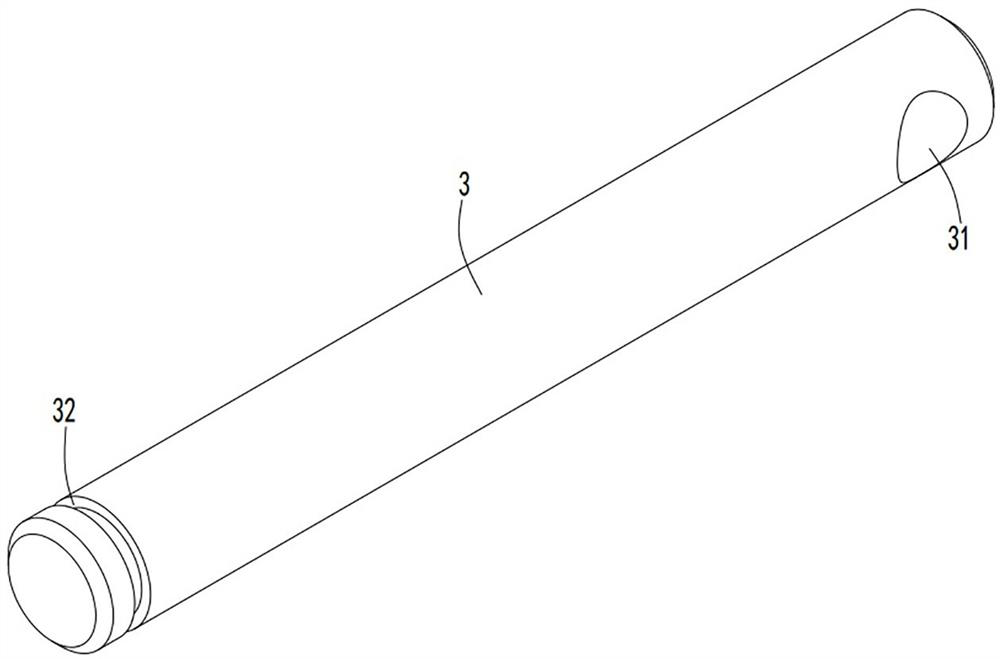

[0025] refer to Figure 1 to Figure 4 , a plastic-coated rotor provided by the present invention includes a rotor housing 1, a plastic-coated body 2 arranged at the bottom of the rotor housing 1, a rotor shaft 3 connected to the plastic-coated body 2, and a plastic-coated body 2 is fitted with the rotor housing 1, and the rotor housing 1, the overmolded body 2, and the rotor shaft 3 are integrally formed, specifically by injection molding.

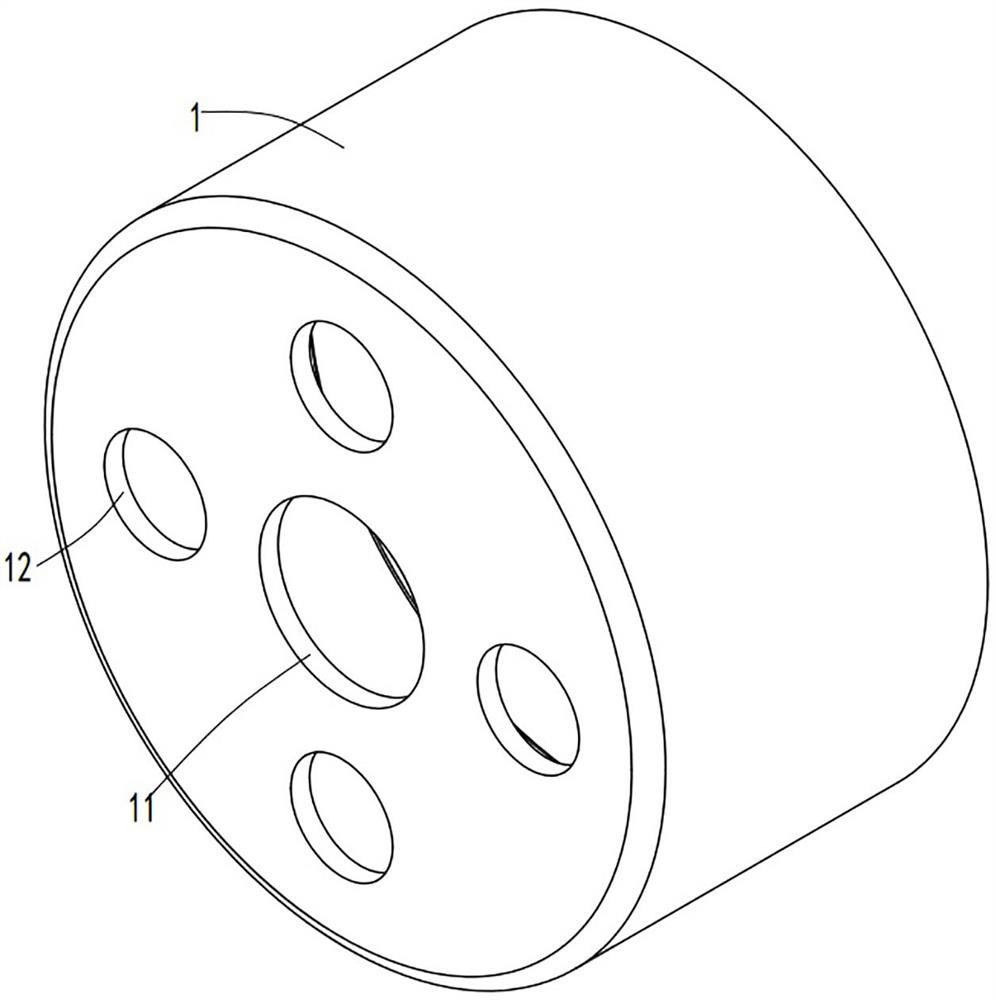

[0026] The bottom of the rotor housing 1 is provided with a first injection runner 11 at a position corresponding to the rotor shaft 3, and a plurality of second injection runners 12 are uniformly arranged at the bottom of the rotor housing 1; the first injection runner 11 and the second injection molding runner 12 run through the bottom of the rotor housing 1, and the overmolding body 2 is connected with the rotor housing 1 through the first injection molding runner 11 and the second injection molding runner 12. During injection molding ...

Embodiment 2

[0037] In this embodiment, there is no restriction on the distribution of the second injection molding runners 12, as long as the distribution is uniform and the structural strength meets the standard, for example, there are more than four, or there is no need to arrange them in a circular array. The rest of the structures are the same as those in Embodiment 1, and will not be repeated here.

[0038] The present invention is provided with a first injection molding flow channel and a second injection molding flow channel at the bottom of the rotor shell, and the distribution of the injection molding flow channels is even and reasonable, which realizes uniform filling in the injection molding process and facilitates the overmolding body and the rotor shell in the injection molding process. The reliable combination of body improves the reliability of the overmolding process. At the same time, the rotor shaft is provided with a third injection molding flow channel, so that the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com