Manufacturing method of embedded cavity and PCB

A manufacturing method and a technology for burying a cavity, which are applied in the manufacturing of printed circuits, printed circuits and electrical components connected with non-printed electrical components, etc. Simple and reliable, high alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

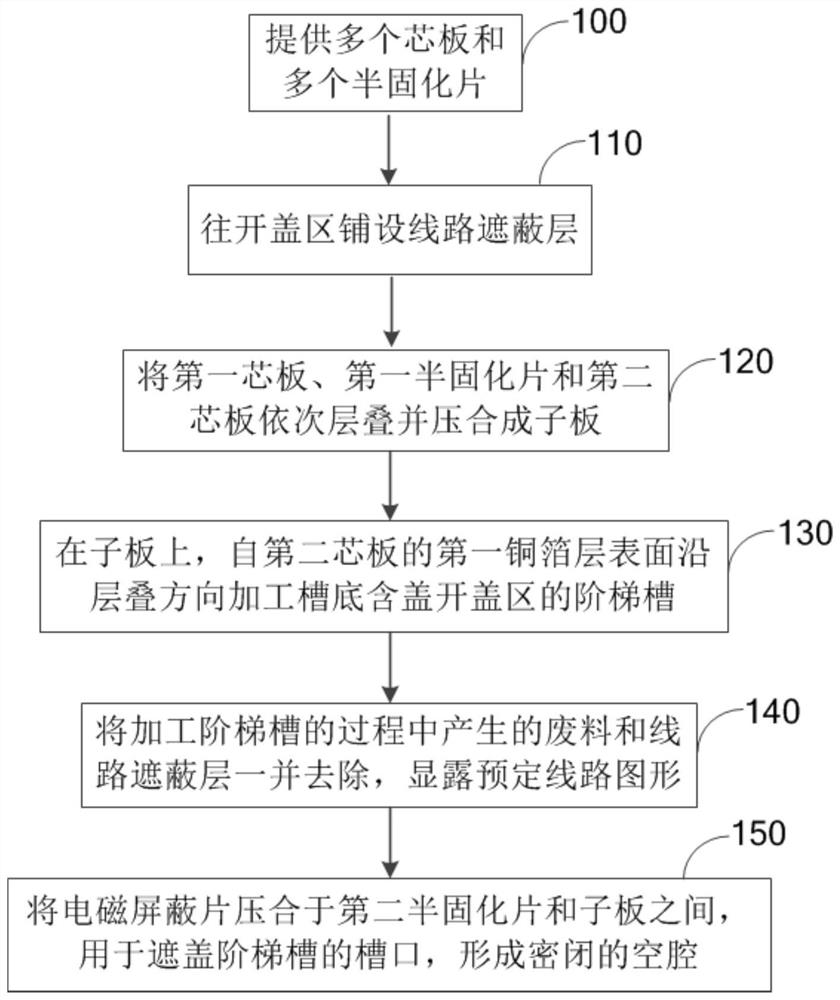

[0047] see figure 1 and figure 2 , the present embodiment provides a method for fabricating a buried cavity, comprising the steps of:

[0048] Step 100 , providing a plurality of core boards 10 and a plurality of prepregs 30 .

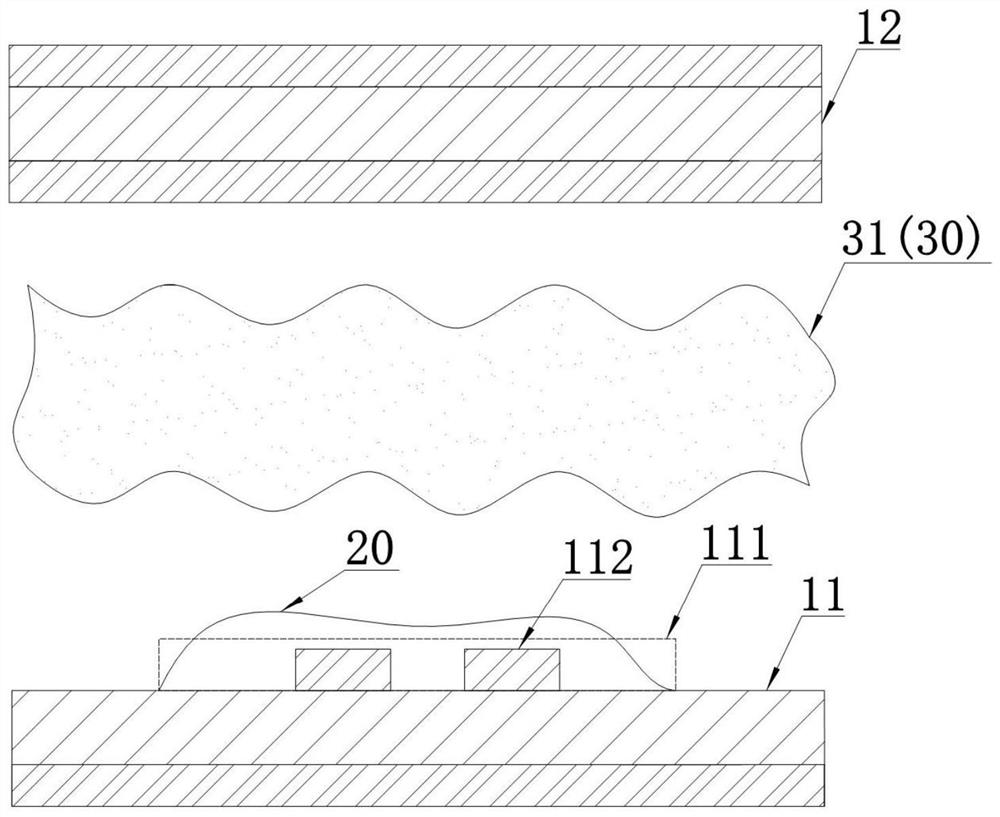

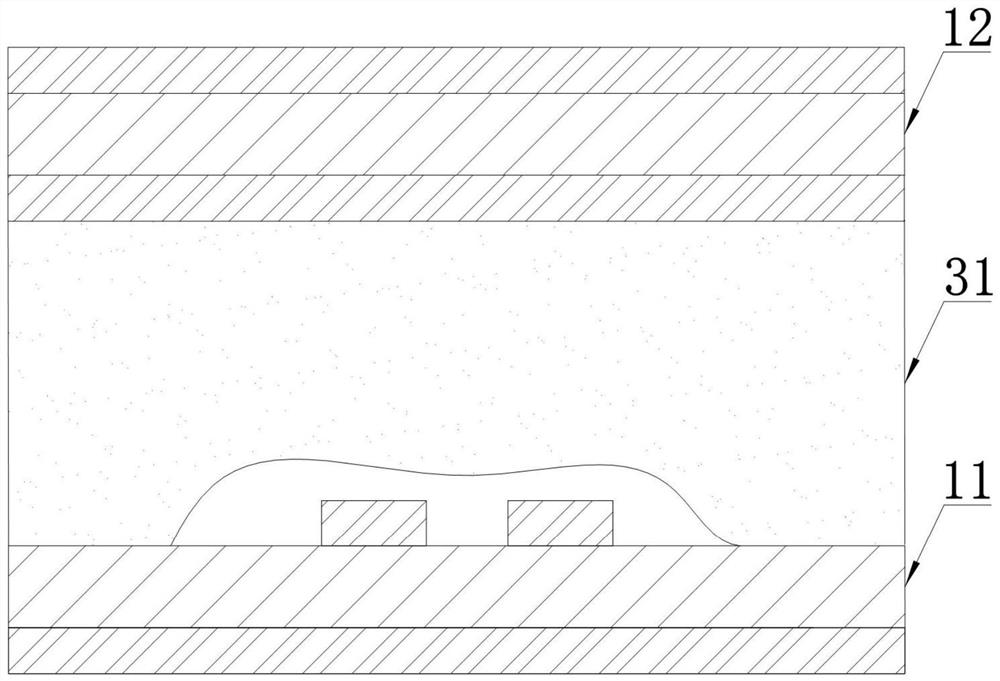

[0049] In this step, the core board 10 includes a first core board 11 and a second core board 12; a predetermined circuit pattern 112 is formed on the surface of the first copper foil layer of the first core board 11; the first copper foil of the first core board The surface of the layer is preset with an opening area 111. It should be noted that according to different application scenarios, the predetermined circuit pattern 112 may be partially or completely located in the opening area 111; the surface of the first copper foil layer of the first core board can also be preset. There are a plurality of opening areas 111;

[0050] The prepreg 30 includes a first prepreg 31 and a second prepreg 32 . In this embodiment, the prepreg 30 is a common prepr...

Embodiment 2

[0084] This embodiment also provides a PCB in which a closed cavity 60 is embedded, and the cavity 60 is fabricated according to the manufacturing method provided in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com