Method for compensating for an error function of a field device in an automation technology system

A technology of automation technology and field equipment, which is applied in the field of error function compensation of field equipment in the automation technology system, and can solve problems such as high cost and time investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

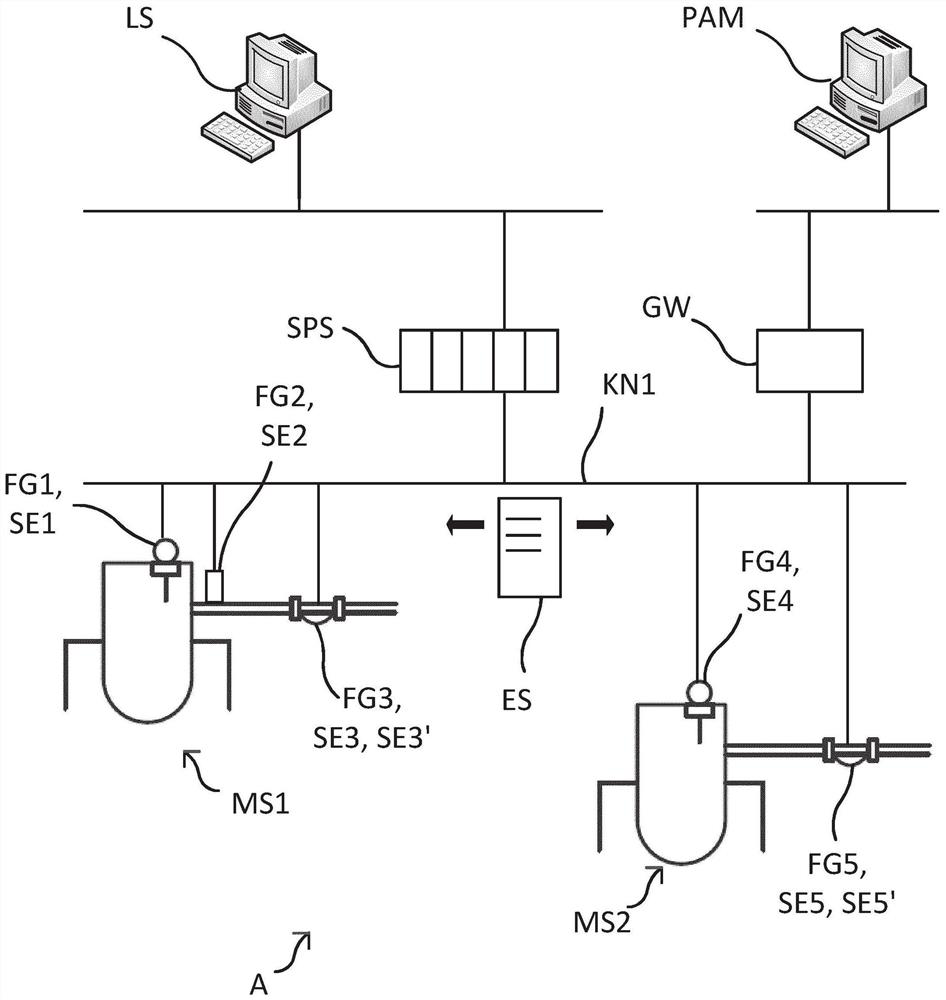

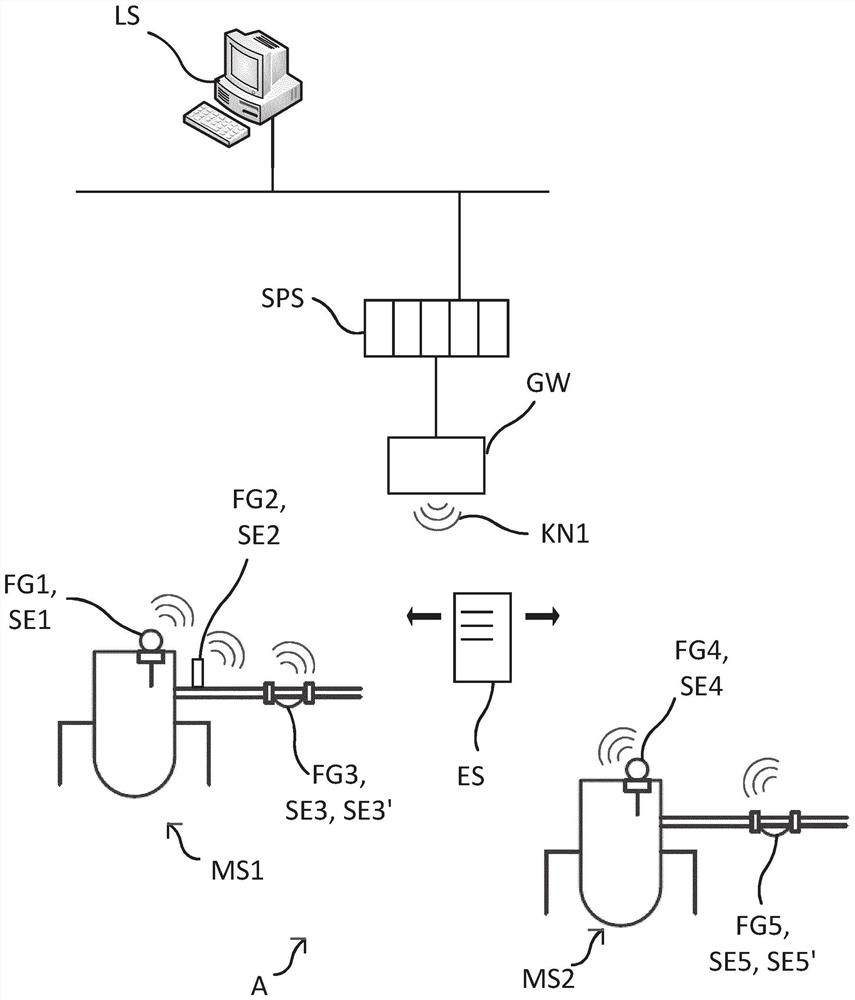

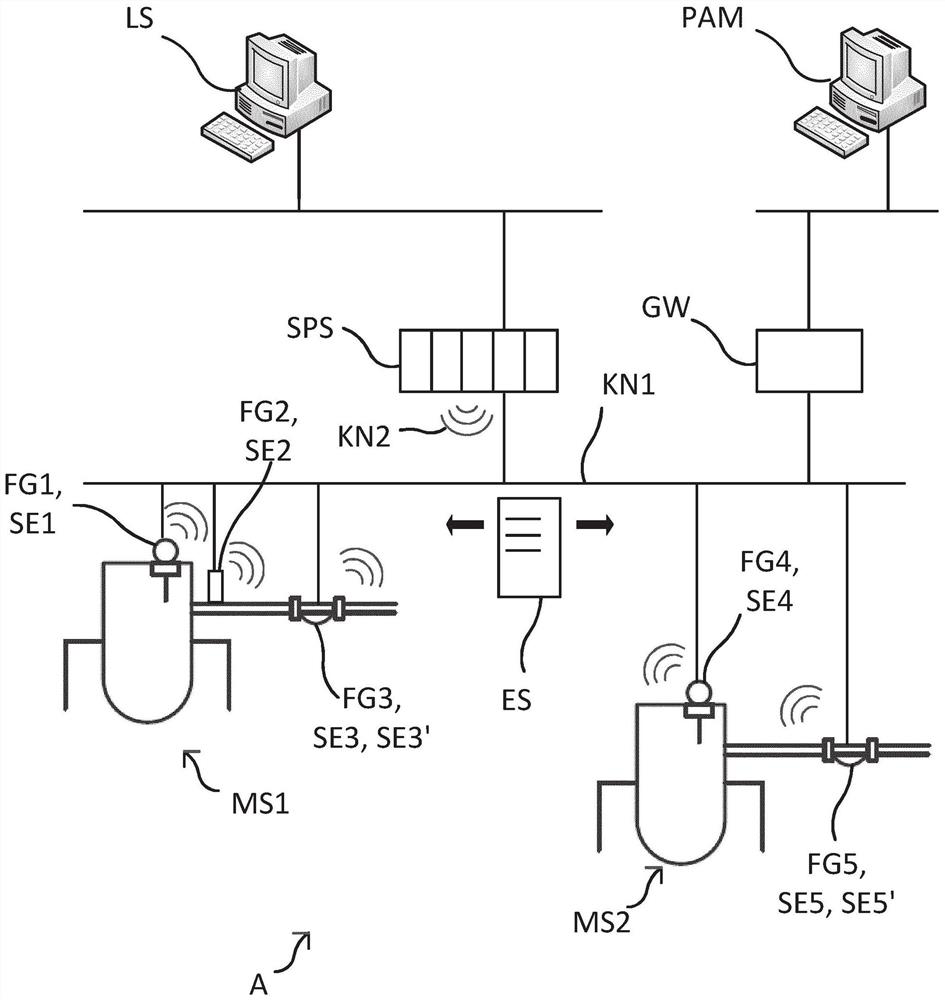

[0033]figure 1 The various parts of the automation technology system A are shown. Specifically, it shows two measurement points MS1, MS2. They respectively consist of a storage tank and a pipeline that drains from the storage tank. In order to measure the liquid level of the storage tank as a process variable, the field devices FG1, FG4 (for example, by means of a radar as a level gauge of the sensor units SE1, SE4) are attached to the storage tank, respectively. In order to measure the flow velocity in the pipeline, field devices FG3 and FG5 are attached respectively, and its sensor units SE3 and SE5 determine the flow velocity of the medium flowing through the pipeline as the main process variable according to the Coriolis principle. Each field device FG3, FG5 also has a temperature sensor SE3', SE5' as another sensor unit, which detects the temperature of the medium flowing through the pipeline as an auxiliary process variable. In addition, another field device FG2 is attached to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com