Small direct-driven type all-metal sealing piezoelectric proportional valve

A direct-drive, all-metal technology, applied in valve details, multi-port valves, valve devices, etc., can solve problems such as high requirements for gasket materials, small working pressure range, and inability to achieve proportional control, and achieve small change, avoid the use environment of alternating force, and have the effect of large output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

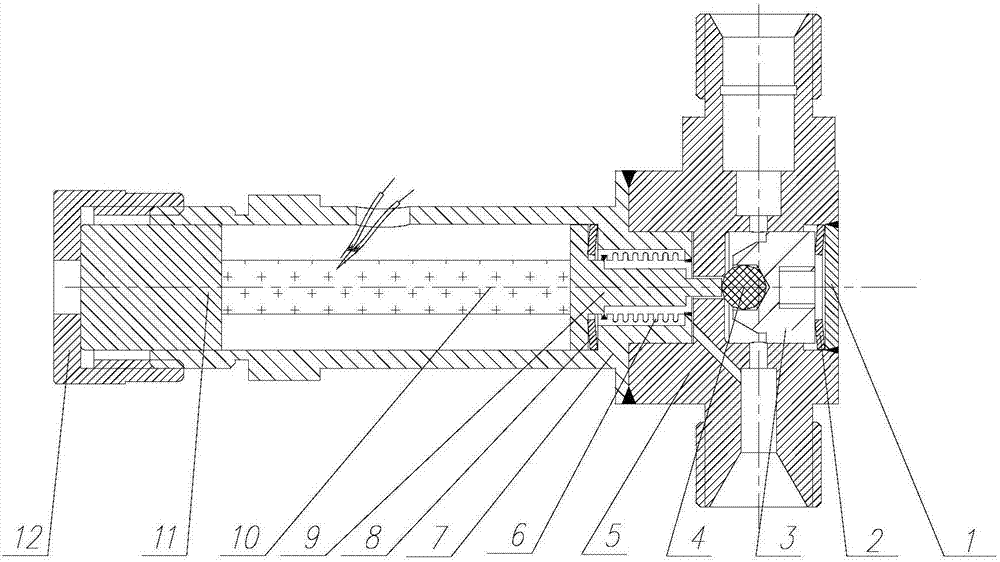

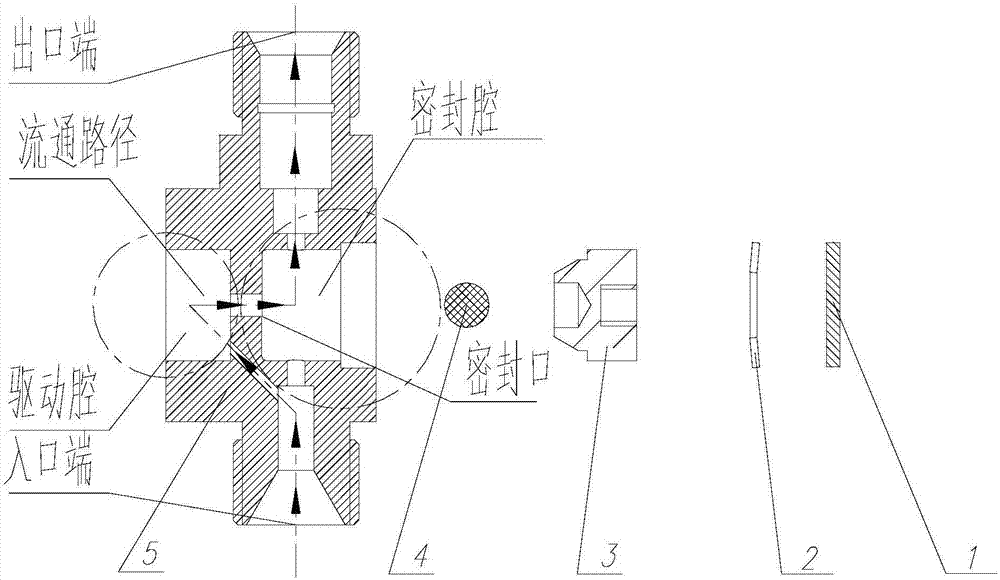

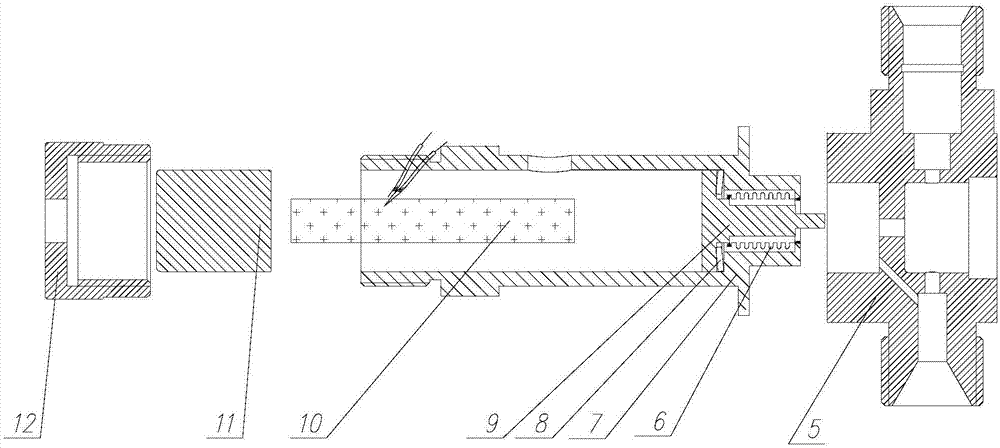

[0030] Such as figure 1 As shown, it is a structural schematic diagram of a direct-drive all-metal sealed piezoelectric proportional valve of the present invention, which mainly includes a pressure plate 1, a sealing disc spring 2, an armature 3, a ceramic ball 4, a valve body 5, a bellows 6, a driver valve body 7, and a Tension disc spring 8, push rod 9, piezoelectric driver 10, push block 11, nut 12. Among them, the ceramic ball 4 is made of hard ceramics, the piezoelectric actuator 10 is ceramics with piezoelectric function, the pressure plate, the sealing disc spring, the armature, the ceramic ball, the valve body, the bellows, the driver valve body, the pre-tightening force disc spring , ejector rod, piezoelectric driver, push block and nut are made of metal.

[0031] The present invention adopts a structure in which the piezoelectric driving part is separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com