Part surface spraying device for automobile production

A technology for surface spraying and parts, which is applied in the field of surface spraying devices for automobile production parts, can solve problems such as uneven spraying and physical injury of operators, and achieve the effect of ensuring the working environment, improving uniformity and improving operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

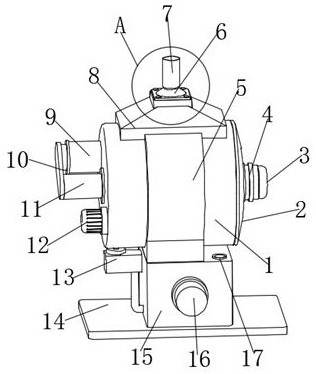

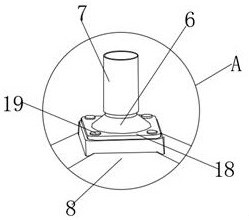

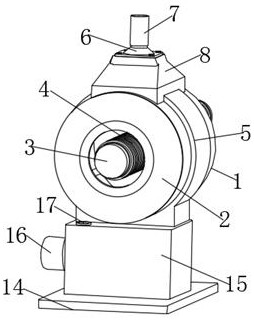

[0027] Such as Figure 1-Figure 7 The shown a kind of surface spraying device for parts used in automobile production comprises a spraying cylinder 1, the top of the spraying cylinder 1 is provided with an exhaust mechanism, and the inside of the spraying cylinder 1 is provided with an expansion mechanism, and the expansion mechanism includes a cylinder fixedly mounted on the inner wall end of the spraying cylinder 1 The limit plate frame 26 at the middle position of the upper part, the limit plate frame 26 and the end of the spraying tube 1 are jointly horizontally slid and inserted with a pull rod 11, both ends of the pull rod 11 extend to the outside of the spray tube 1, and the pull rod 11 is far away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com