Keyboard rubber die cutting production method and production system

A production method and plastic mold technology, applied in metal processing and other directions, can solve problems such as unfavorable factory production, waste of consumable resources, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

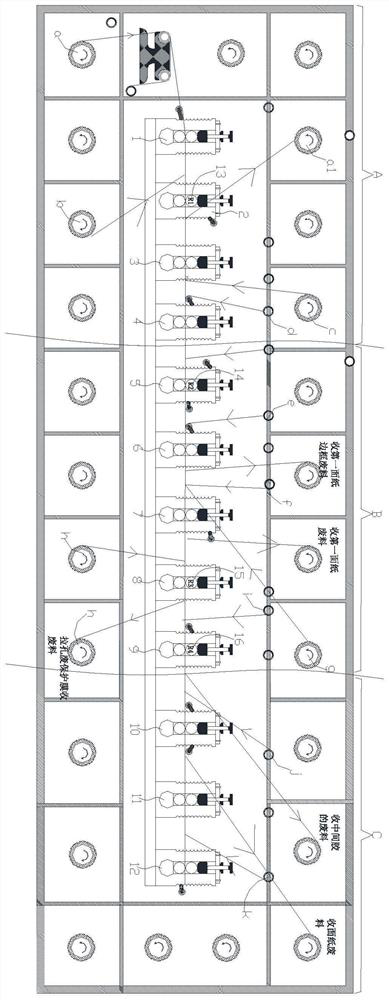

[0050] figure 1 Schematically shows a keyboard rubber die-cutting production method according to an embodiment of the present invention, comprising the following steps,

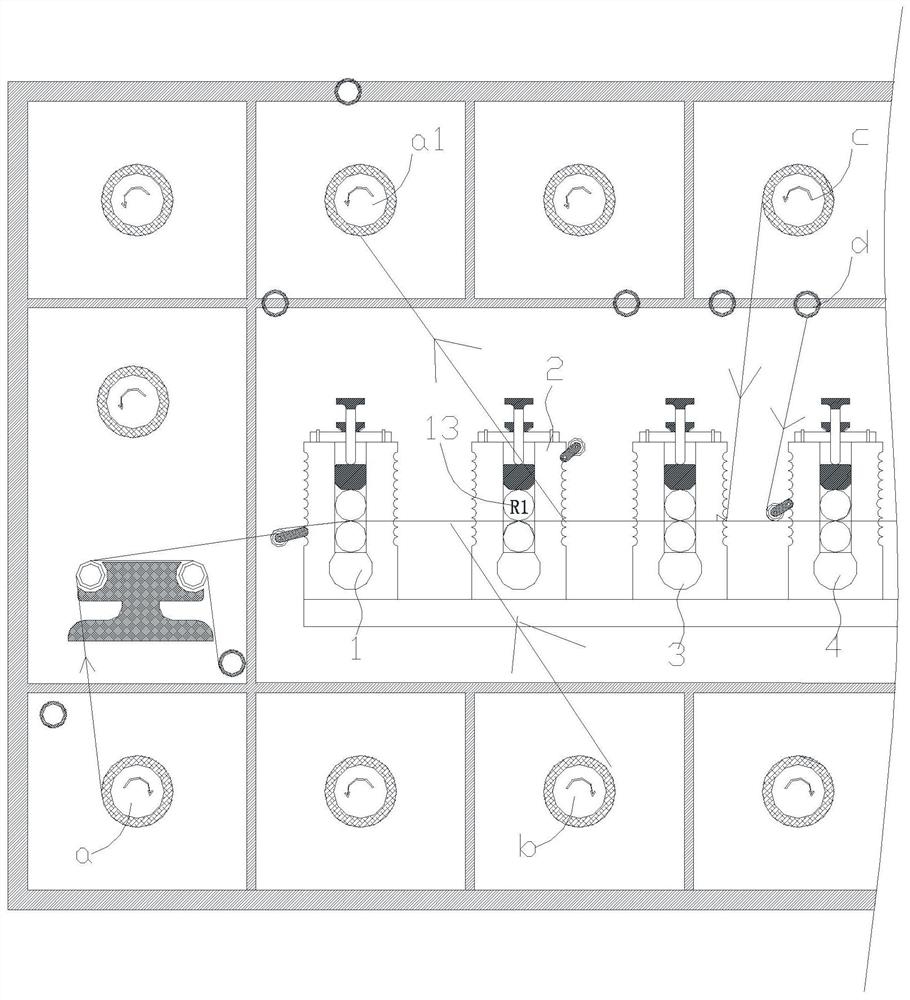

[0051] Feeding: Input the first material belt a, the first material belt a includes the shipping protection film a1 and the first release film a2;

[0052] S1: Input the bottom protective film b from below, so that the bottom protective film b is attached to the above-mentioned film material;

[0053] S2: Die cutting with R1 rolling knife 13, and discharge part of the first release film a2 from above;

[0054] S3: Input the waste lifting mat c and the first face paper d sequentially from above, so that the waste lifting mat c and the first face paper d are bonded to the above-mentioned film material;

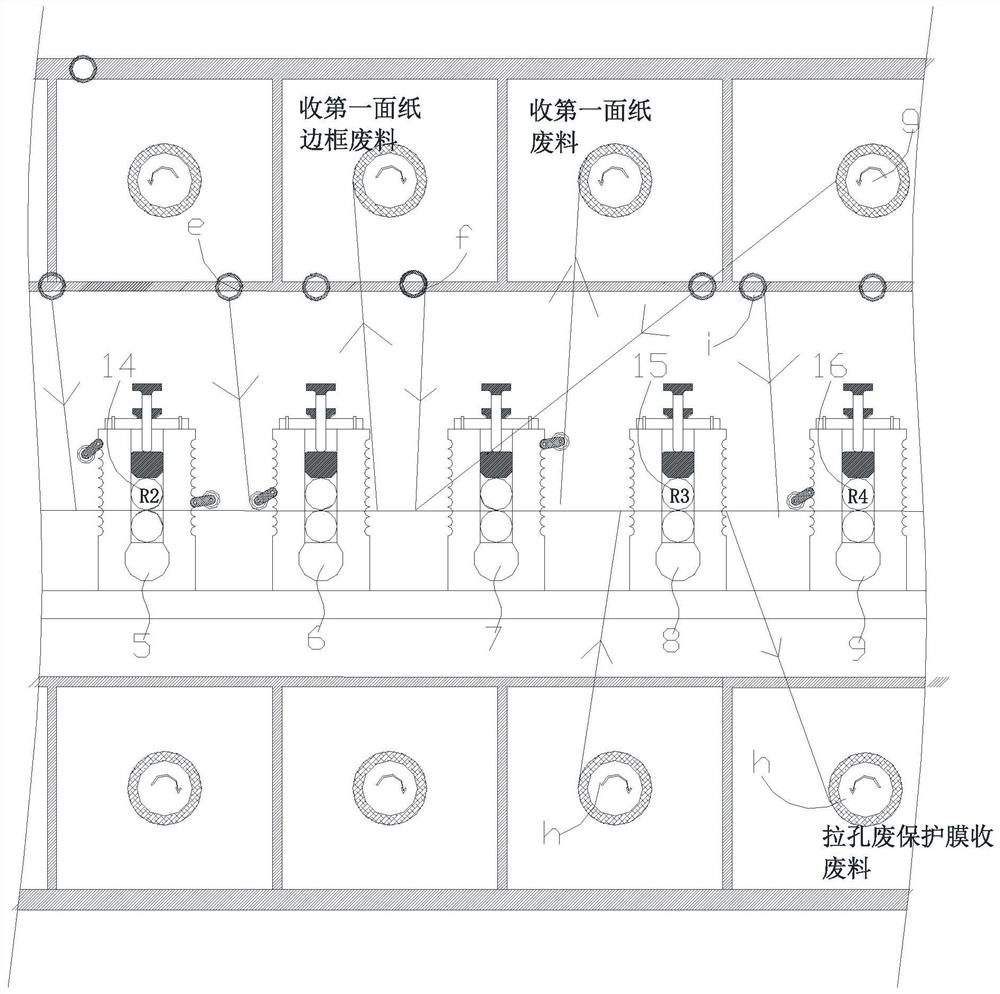

[0055] S4: Die cutting with R2 rolling knife 14, input the first waste lifting tape e f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com