Measurement method of weak mud pulse pressure wave under high standing pressure

A technology of mud pulse and measurement method, which is applied in the direction of pressure difference measurement, measurement, and measurement devices among multiple valves, to achieve accurate measurement, reduce bit error rate, and the effect of simple and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

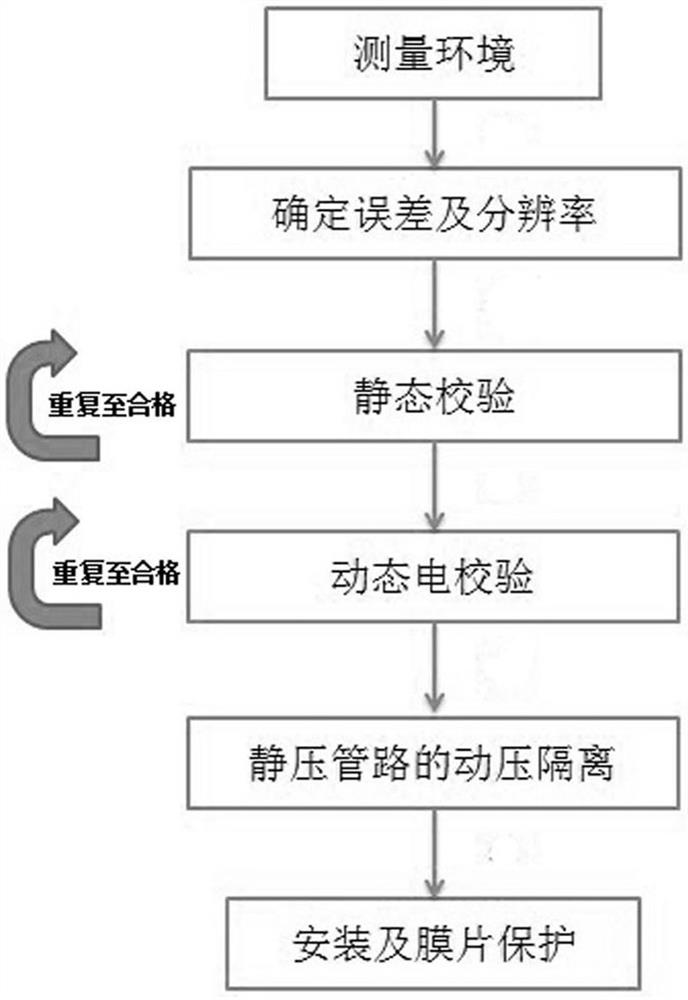

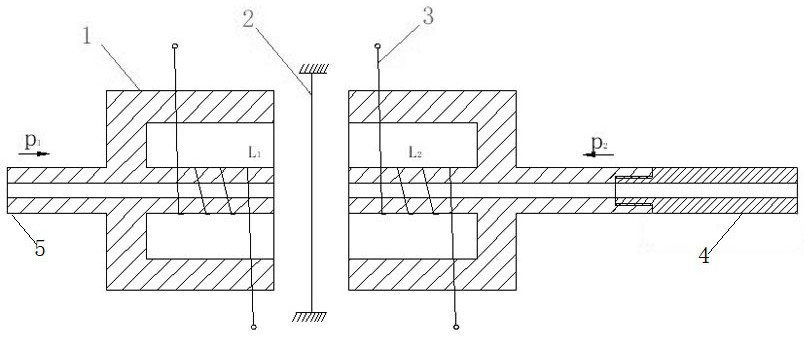

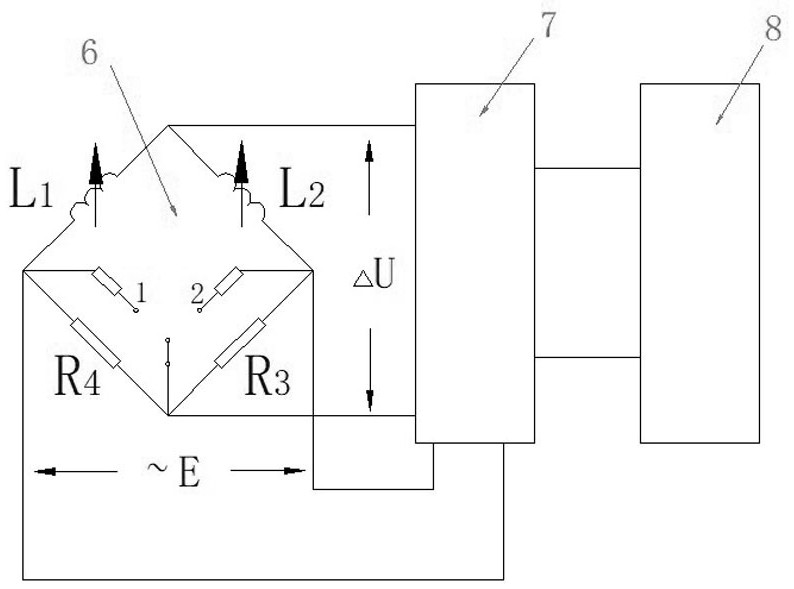

[0035] Embodiment 1: as attached Figures 1 to 3 As shown, the measurement method of the weak mud pulse pressure wave under high vertical pressure includes the following steps:

[0036] The first step: determine the error and resolution;

[0037] According to the measured mud pulse pressure amplitude, select a differential pressure sensor with appropriate range, error and resolution.

[0038] If the maximum amplitude of the measured mud pulse is 0.1MPa and the maximum allowable absolute error is 0.01MPa, the total accuracy of the measurement system is required to be better than 10%. If a differential pressure sensor with a total error of less than 5% is selected, the maximum allowable absolute error is 0.01MPa. It is required that the maximum range of the measurement system (differential pressure sensor) does not exceed 0.2MPa, so choosing a differential pressure sensor with a range of 0.1MPa to 0.2MPa can ensure the required measurement accuracy, and choosing a static range ...

Embodiment 2

[0058] Embodiment 2: Measurement environment: standpipe pressure 35 MPa, pulse signal pressure amplitude 0.5 MPa, ratio of dynamic pressure to static pressure 1.4%. The waveform of the dynamic pressure is as Figure 4 shown.

[0059] For this measurement environment, the measurement method of the weak mud pulse pressure wave under high vertical pressure includes the following steps:

[0060] (1) Determine the error and resolution

[0061] Using the error theory about the error relationship between the measuring tool and the detected object, the ratio of the random error of the measurement system to the fluctuation of the measured signal should be less than 1 / 3, that is, under the condition of 35MPa standpipe pressure, the total accuracy should be better than 1.4%×1 / 3=0.5%, the absolute error of measurement should not be greater than 0.5MPa×1 / 3=0.17MPa. The lowest measurable vibration level in the process of dynamic pressure measurement is when the signal-to-noise ratio is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com