Air seal type wet spraying machine material distributing device and using method

A technology of a material distribution device and a wet spraying machine, which is applied in the field of mechanical processing, can solve the problems affecting the stability and reliability of the operation of the shotcrete feeding operation, and the inability to effectively convey and distribute the materials at the discharge port of the material distributor. It can improve the stability of the feeding operation, the operation efficiency and quality stability of the shotcrete operation, the good material distribution ability, and the high processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

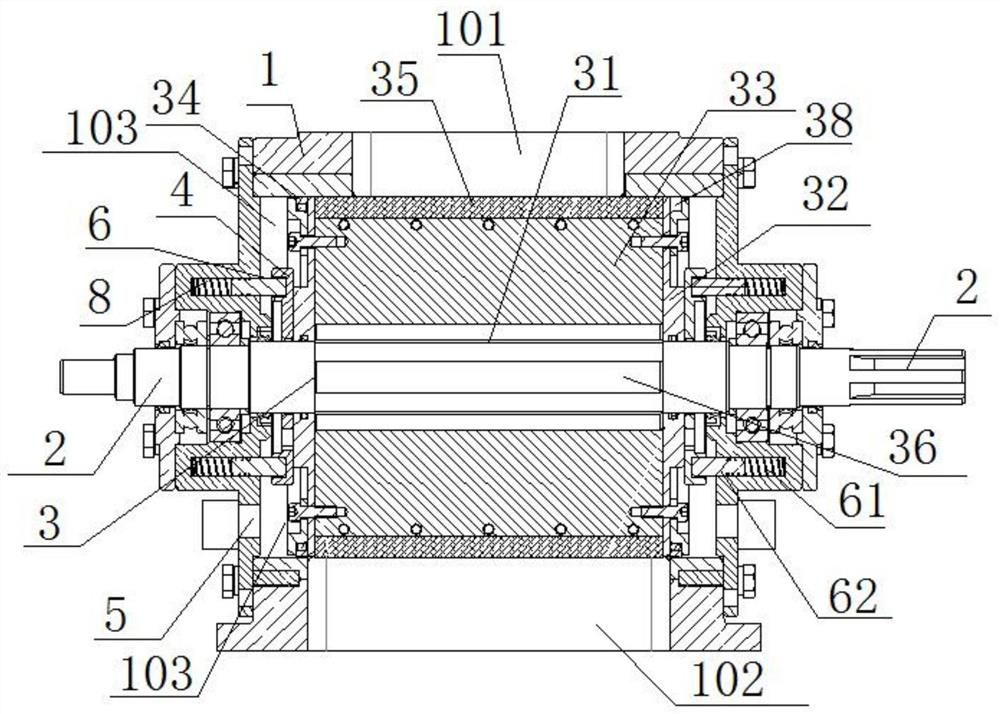

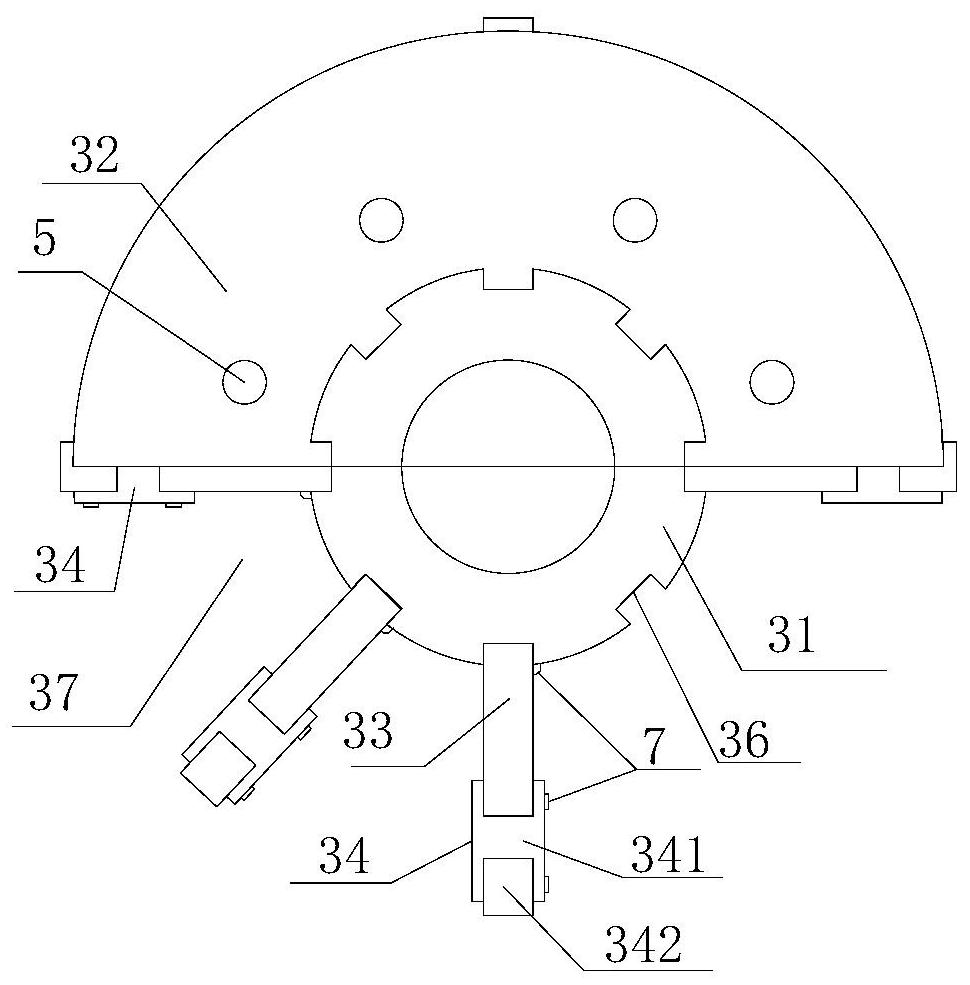

[0020]Such asfigure 1 with2As shown, an air-sealed wet spraying machine material distributing device includes a material barrel 1, a transmission shaft 2, a material distributing wheel 3, a sealing baffle 4, and an air inlet 5, wherein the material barrel 1 is a cylindrical closed cavity structure , The barrel 1 is provided with an outlet 101 and an inlet 102 respectively, the outlet 101 and the inlet 102 are communicated with the barrel 1, and the distribution wheel is embedded in the barrel 1 and connected with the barrel 1. Distributed coaxially, the front and rear ends are respectively connected to the side wall of the barrel 1 through the transmission shaft 2, and are coaxially distributed with the transmission shaft 2, and the front ends of the transmission shaft 2 are respectively located outside the barrel 1, and the distributing wheel is located at the outlet Between the inlet 101 and the inlet 102, the length of the dividing wheel 3 is greater than the width of the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com